Advantages and Challenges of Multi-Cavity Bucket Moulds

In the production of complex plastic buckets, such as those with handles, lids, or integrated bucket-lid assemblies, the choice between single-cavity and multi-cavity moulds is a critical decision. Multi-cavity Bucket Moulds allow multiple parts to be produced simultaneously, offering potential improvements in production efficiency and cost-effectiveness. However, designing and operating these moulds introduces technical challenges that must be carefully managed to ensure product quality and consistency.

Efficiency and Production Volume Benefits

One of the primary advantages of multi-cavity moulds is their ability to significantly increase output. For high-volume production of complex buckets, a multi-cavity Bucket Mould can reduce cycle time per unit and improve machine utilization. This causes lower labor and energy costs per piece compared to single-cavity moulds. Additionally, producing multiple buckets per cycle allows manufacturers to meet market demand more quickly, which is particularly valuable in industries where seasonal or bulk demand fluctuates.

Consistency and Quality Considerations

Multi-cavity moulds can enhance product consistency if designed and maintained properly. Each cavity must be balanced to ensure even distribution of molten plastic, preventing variations in wall thickness, shrinkage, or surface finish. Achieving this balance requires precise flow analysis, optimized gate placement, and careful temperature control. Single-cavity moulds, while simpler, are less prone to flow imbalances, but they cannot match the output rate of multi-cavity systems in large-scale production.

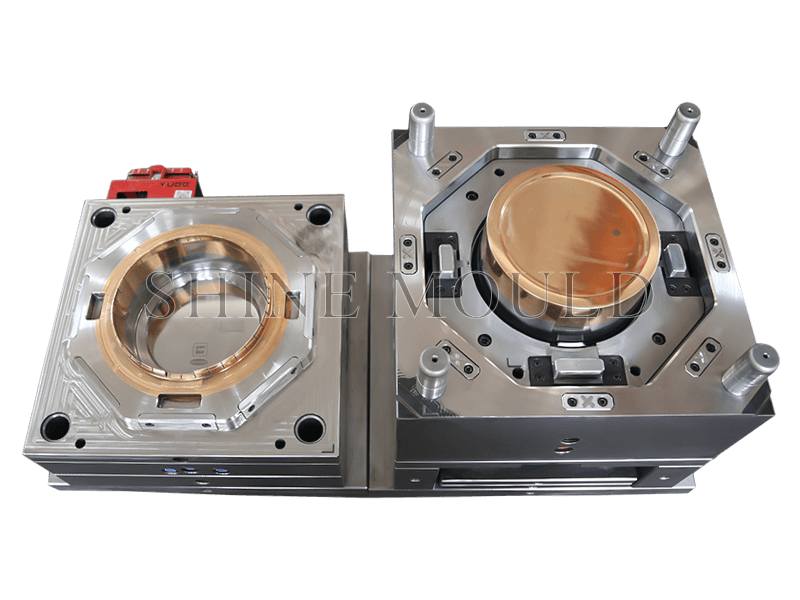

Challenges in Complex Bucket Design

Buckets with handles, lids, or interlocking components present unique challenges for multi-cavity moulds. The increased complexity can make it difficult to maintain uniform filling across all cavities, particularly for thicker sections such as reinforced handles or lid lips. Cooling systems must be carefully designed to prevent warping or sink marks, and ejector systems need to ensure smooth removal of all parts without deformation. Additionally, multi-cavity moulds require more precise alignment and higher-quality materials to withstand the mechanical stresses of repeated cycles.

Maintenance and Cost Implications

While multi-cavity Bucket Moulds offer efficiency advantages, they are more expensive to design and manufacture than single-cavity alternatives. The initial investment is higher due to more complex machining, increased steel usage, and additional components such as multiple gates and runners. Maintenance can also be more demanding, as wear or damage in one cavity can affect the performance of the entire mould. Regular inspection and preventive maintenance are critical to reduce downtime and maintain consistent product quality.

Material and Flow Optimization

Selecting the right plastic material and optimizing flow is especially important for multi-cavity moulds. Different plastics have varying viscosities and shrinkage rates, which influence how evenly they fill all cavities. Designers often use simulation software to predict flow patterns and adjust gate locations, runner sizes, and cooling channels accordingly. For complex bucket designs, such optimization ensures that all parts meet dimensional and structural requirements without defects.

Multi-cavity Bucket Moulds provide clear advantages in production speed, efficiency, and potential consistency for complex bucket designs with handles, lids, or assemblies. However, these benefits come with challenges in flow balancing, cavity alignment, cooling, and maintenance. Proper design, material selection, and process optimization are essential to fully realize the potential of multi-cavity moulds while reducing risks. When implemented effectively, multi-cavity systems can significantly enhance the competitiveness and profitability of large-scale bucket manufacturing operations.

Search...

Search... English

English

.jpg)

.jpg)