Assessing Deformation Risks of Package Mould Under Conditions

The Challenges of High-Temperature and High-Pressure Operations

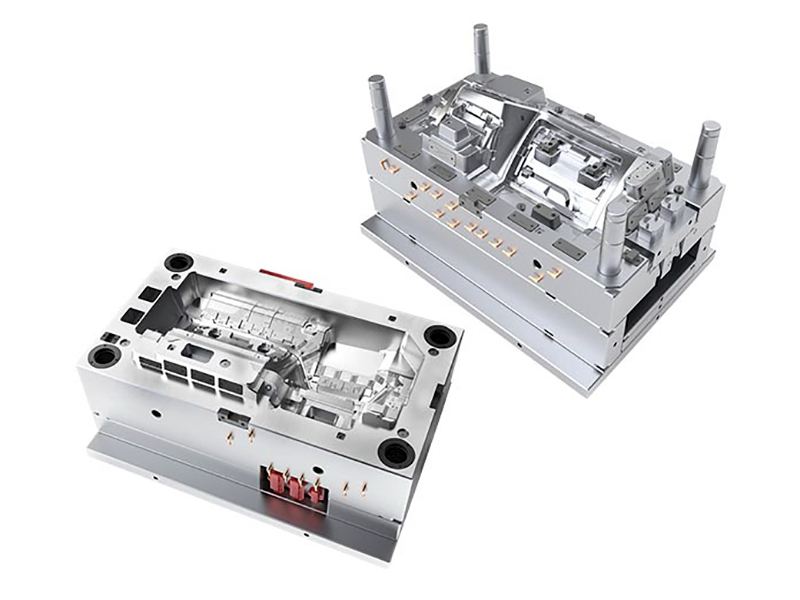

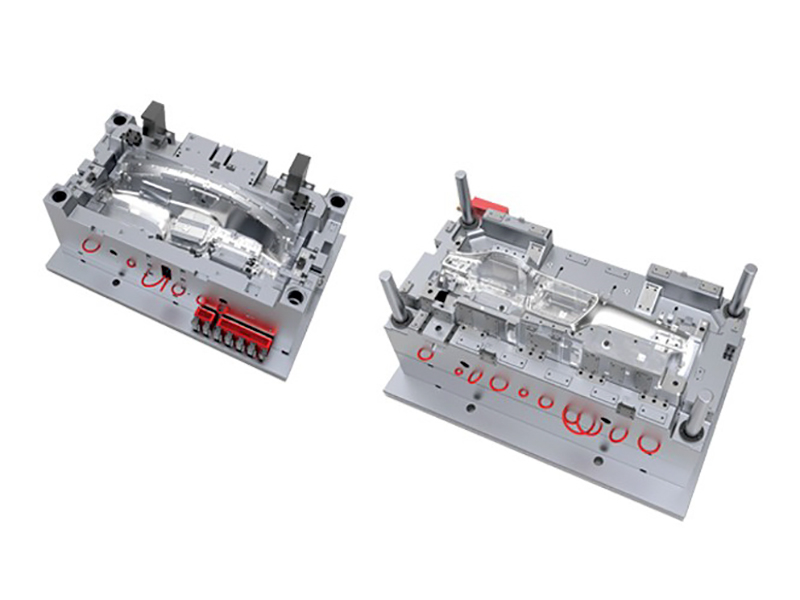

Package moulds are critical components in modern packaging production, shaping materials into consistent and precise products. During production, these moulds are often exposed to high temperatures and pressures, especially in processes such as injection molding, thermoforming, or compression molding. Maintaining dimensional stability under such conditions is essential to ensure product quality, reduce defects, and extend the service life of the mould. Understanding how high temperature and pressure affect mould performance is crucial for both design engineers and production managers.

Thermal Effects on Mould Integrity

High temperatures can significantly impact the structural stability of a package mould. When exposed to heat, metals expand, which may cause slight dimensional changes. For molds not specifically engineered to withstand elevated temperatures, this thermal expansion can result in warping, misalignment of cavities, or uneven surface finish on the final product. Additionally, repeated heating and cooling cycles can cause thermal fatigue, weakening the material over time and increasing the risk of permanent deformation. Selecting heat-resistant materials and implementing proper cooling channels are therefore critical design considerations.

Pressure-Induced Deformation

High pressures during molding processes exert substantial mechanical forces on the mold. Excessive pressure can cause elastic or even plastic deformation in areas that are not adequately reinforced. Moulds with thin walls or unsupported sections are particularly susceptible. Pressure-related deformation can cause variations in product dimensions, poor material flow, and defects such as flash or incomplete filling. Designing moulds with sufficient wall thickness, structural reinforcements, and stress-distributing geometries can mitigate these risks and ensure reliable performance under high-pressure conditions.

Material Selection and Surface Treatment

The choice of material plays a decisive role in preventing deformation under certain conditions. High-quality tool steels, hardened alloys, or composite materials are commonly used to enhance strength and thermal stability. Surface treatments, such as nitriding or coating with wear-resistant layers, improve durability and reduce the effects of thermal stress and friction. Combining robust materials with precise heat treatment ensures that the package mould maintains its shape, tolerances, and smooth surface finish even under prolonged exposure to challenging operational conditions.

Design Considerations for Stability

Modern package moulds are designed with stability in mind, incorporating features such as reinforced ribs, optimized cavity layouts, and strategically placed cooling channels. These design strategies help distribute heat and mechanical stress more evenly, reducing the likelihood of deformation. Finite element analysis (FEA) and computer-aided simulations are often used during the design phase to predict potential weak points and optimize structural integrity. Properly designed moulds can withstand high-temperature and high-pressure cycles while maintaining dimensional accuracy and consistent product quality.

Maintenance and Operational Practices

Even well-designed moulds require regular maintenance to maintain their stability under certain conditions. Monitoring for signs of wear, micro-cracks, or surface deformation is essential. Ensuring that production parameters, such as temperature and pressure, remain within recommended limits reduces stress on the mould. Regular maintenance and careful operation extend the lifespan of the mould and prevent costly production downtime caused by deformation or failure.

Ensuring Reliable Performance in Conditions

Package moulds can experience deformation if not properly designed, manufactured, and maintained for high-temperature and high-pressure conditions. Material selection, structural reinforcement, thermal management, and precision design are essential to reduce risks. By understanding and addressing the challenges of operational environments, manufacturers can maintain dimensional accuracy, ensure product quality, and prolong the service life of package moulds, ultimately improving overall production efficiency and reliability.

Search...

Search... English

English

.jpg)