Bucket Mould processing capacity

Plastic bucket design ability

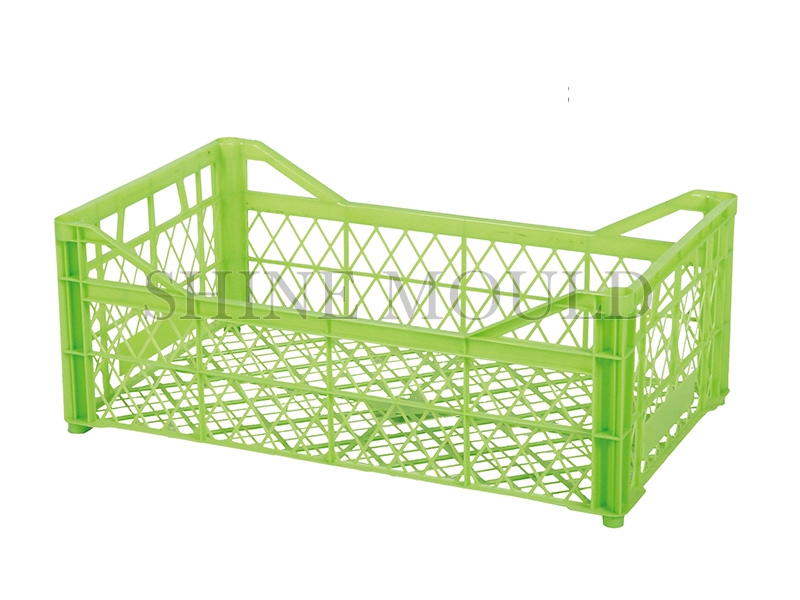

The success or failure of a business mainly depends on the product, so the development and manufacture of more competitive and exquisite plastic buckets is a key process of your plastic bucket business.

Bucket Mould's design capabilities

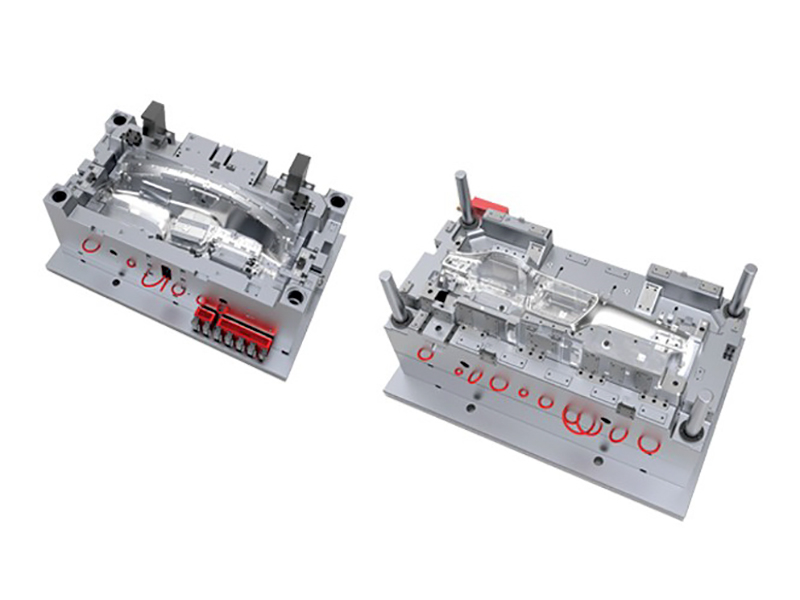

You may encounter the following challenge: "How can I produce plastic barrels as efficiently and profitably as possible?" Simply start with three aspects: mold structure, mold steel, and mold cooling.

Applicable mold structure

Depending on the details of the plastic bucket, such as the slider design that may not be needed when the bucket is straight and simple; the mechanical ejection design, where the robot automatically drops or collects; a certain fixed design for further thermal transfer printing.

Applicable die steel

It should be considered in conjunction with the production requirements of plastic barrels. The steel of different mold parts may be different, such as P20, 718H, H13, and DIN1.2316... The final customer will get a more cost-effective mold.

Optimal mold cooling

When customers require shorter and shorter cycle times, the cooling design will do well. In addition to the best cooling channels, Cu-Be inserts also help better cooling. The main part can be the bottom area and the top ribs. area.

Bucket Mould processing capacity

If the design of the plastic barrel and its mold is done well, the mold processing will be very easy and the size will be controlled if the quality of the mold equipment is good. For Bucket Mould, due to the high requirements for eccentricity and tightness, the requirements for tooling machines are also high.

Drawer Mould is also our product, welcome to consult and purchase.

Search...

Search... English

English

.jpg)