Cabinet Mould Creating Functional and Aesthetically Pleasing Storage

Cabinet moulds play a crucial role in the manufacturing of cabinets, providing the foundation for functional and visually appealing storage solutions. With their precise design and construction, cabinet moulds allow for the production of cabinets that are durable, customizable, and seamlessly integrated into various spaces. In this article, we will delve into the significance of cabinet moulds and explore the key aspects involved in their creation.

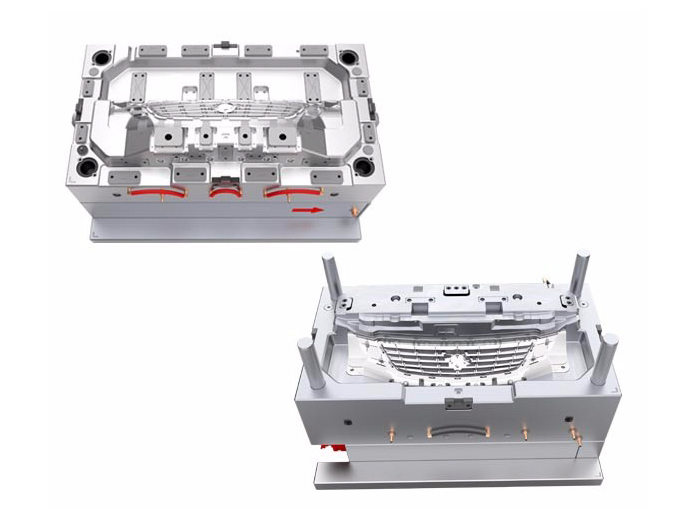

Cabinet moulds are meticulously designed to ensure accuracy and precision in the manufacturing process. Collaborating with experienced designers and engineers, manufacturers can create moulds that align with their specific cabinet designs and functional requirements. The customizability of cabinet moulds allows for variations in size, shape, and features, enabling the production of cabinets that cater to diverse needs and spaces.

The choice of material for cabinet moulds is crucial in determining the durability and longevity of the produced cabinets. Commonly used materials for cabinet moulds include steel, aluminium, and composite materials. Steel moulds offer exceptional durability, heat resistance, and a long lifespan, making them suitable for high-volume production. Aluminium moulds provide advantages such as faster cooling and reduced cycle times, making them ideal for smaller production runs. The selection of the appropriate material depends on factors such as production requirements, budget, and desired cabinet quality.

Cabinet moulds require meticulous attention to detail to ensure the precise replication of intricate cabinet features. From panelling and joinery to hardware placements and edge profiles, the mould design must capture every element of the desired cabinet design. Intricate details, such as grooves, handles, or decorative elements, are carefully incorporated into the moulds to achieve the desired aesthetics and functionality of the final cabinets.

Efficiency in cabinet production is greatly influenced by the design and construction of cabinet moulds. The moulds should be constructed to allow for quick and accurate assembly, disassembly, and part ejection. Proper venting and cooling channels are incorporated into the mould design to facilitate efficient heat dissipation and reduce cycle times. By optimizing the production processes through well-designed cabinet moulds, manufacturers can increase productivity and meet production targets effectively.

Maintaining consistent quality is of utmost importance in cabinet manufacturing. Cabinet moulds play a significant role in achieving this consistency. Regular quality control assessments ensure that the moulded cabinets meet the required standards for dimensions, finish, and functionality. Proper maintenance of the cabinet moulds, including cleaning, lubrication, and inspection, is crucial in ensuring the long-term consistency and quality of the produced cabinets.

Cabinet moulds allow for innovation and customization in cabinet design. Manufacturers can experiment with different materials, finishes, and styles to create unique and appealing cabinets. By incorporating innovative features into the mould design, such as hidden storage solutions, ergonomic considerations, or smart functionality, manufacturers can meet the evolving needs and preferences of consumers, offering them modern and functional storage solutions.

Cabinet moulds are instrumental in creating functional and aesthetically pleasing storage solutions. Through precision design, material selection, attention to detail, and efficient production processes, manufacturers can produce cabinets that are customized, durable, and consistent in quality. The versatility and innovation offered by cabinet moulds allow manufacturers to meet the diverse demands of consumers, ensuring that cabinets are not only practical but also enhance the overall design and functionality of various spaces. By prioritizing precision and quality in cabinet mould creation, manufacturers can deliver storage solutions that elevate both form and function.

Search...

Search... English

English