Cabinet Moulds Precision in Manufacturing

Cabinet moulds, often referred to as cabinet moulds, are specialized tools used in the manufacturing of cabinets and furniture components. They are designed to shape and form various cabinet parts, such as doors, drawers, and decorative trim, with precision and consistency. These moulds are a key component of the woodworking and cabinetry industry, ensuring that the final products meet exacting standards for quality and aesthetics.

The manufacturing process for cabinet moulds is a complex and precise one. It typically involves the following steps:

Design and Engineering: Before any cabinet mould can be created, a detailed design and engineering phase is essential. This phase includes the use of computer-aided design (CAD) software to create a 3D model of the desired cabinet component. Engineers and designers work closely to ensure that the mould will produce the exact shape and dimensions required.

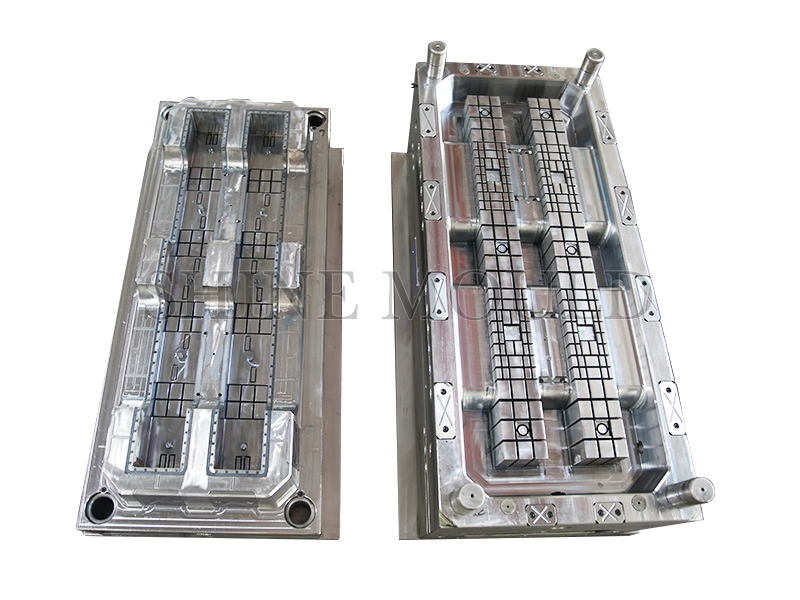

Material Selection: Once the design is finalized, the choice of materials for the mould is critical. The mould material must be durable, heat-resistant, and capable of withstanding the pressure exerted during the cabinet manufacturing process. Common materials used for cabinet moulds include steel and aluminium.

CNC Machining: The 3D model of the cabinet component is used to program a computer numerical control (CNC) machine. This machine precisely carves the mould shape from the chosen material. The accuracy of the CNC machining is vital to ensure that the final cabinet part will be an exact replica of the design.

Heat Treatment: Some cabinet moulds may undergo heat treatment processes to improve their strength and durability. This step is crucial in extending the lifespan of the mould, as it will be subjected to repeated use.

Finishing: After the mould is machined and heat-treated, it may undergo a finishing process to smooth any rough edges and add protective coatings. This ensures that the mould is ready for its role in cabinet production.

Testing and Quality Control: Before the cabinet mould is put into use, it undergoes rigorous testing to ensure that it produces cabinet components that meet the required specifications. Quality control checks are conducted to verify the mould's precision and consistency.

Cabinet moulds are invaluable to cabinet and furniture manufacturers, as they enable the mass production of high-quality products. These moulds ensure that each cabinet part is uniform and consistent, reducing the need for time-consuming manual adjustments and improving overall efficiency.

In addition to their role in mass production, cabinet moulds also play a significant role in custom cabinetry. Skilled artisans and cabinetmakers use moulds to create unique and intricate designs that meet their client's specific requirements. Cabinet moulds, in this context, act as tools that help turn creative visions into reality.

Cabinet moulds are vital components of the woodworking and cabinetry industry. They enable precision, consistency, and efficiency in the production of cabinets and furniture. The process of designing and manufacturing these moulds is a careful and meticulous one, involving detailed engineering, material selection, CNC machining, heat treatment, finishing, and quality control. Whether used in mass production or custom cabinetry, cabinet moulds are the unsung heroes of the industry, shaping the furniture we use and admire in our homes and workplaces.

Search...

Search... English

English

.jpg)