Critical Cavity and Wall Thickness Design for Armchair Moulds

Importance of Cavity Design in Armchair Moulds

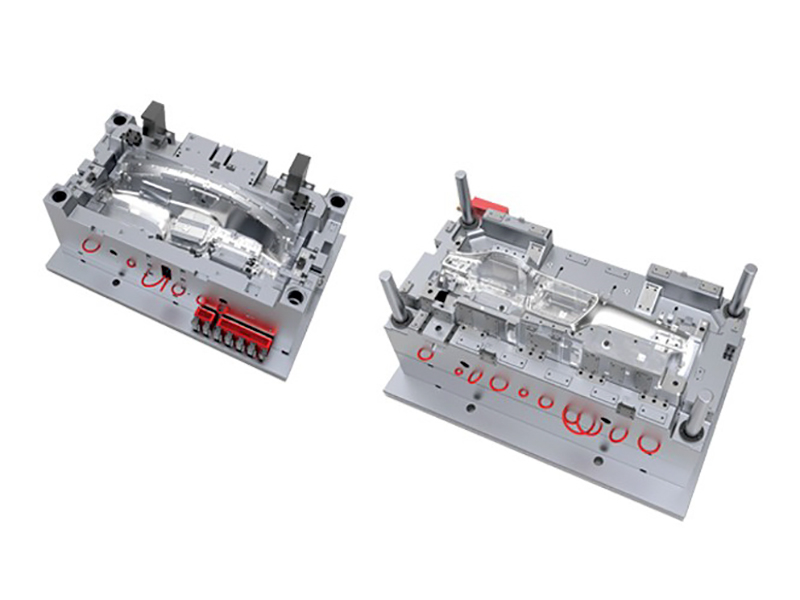

In the production of plastic chairs with both armrests and backrests, the cavity design of an Armchair Mould is a key factor that determines product quality, structural integrity, and manufacturing efficiency. Each cavity must accurately replicate the complex geometry of the chair, including ergonomic contours, armrest angles, and backrest curvature. Improper cavity design can cause defects such as sink marks, warpage, and uneven surface finish, which compromise both aesthetics and functionality. Engineers must pay careful attention to draft angles, radii, and transitions to facilitate smooth ejection and consistent filling.

Wall Thickness Considerations for Strength and Stability

Wall thickness uniformity is critical for ensuring strength and stability in molded plastic chairs. Inconsistent wall thickness can cause differential cooling rates, causing warpage, sink marks, or even structural weaknesses. For armchairs, certain areas, such as the seat and backrest junctions or the points where the armrest connects to the legs, often experience higher stress during use. These areas require careful reinforcement through controlled wall thickness. A balanced approach is necessary to avoid over-thick sections, which can increase material usage, extend cycle times, and create internal stresses.

Addressing Complex Geometries

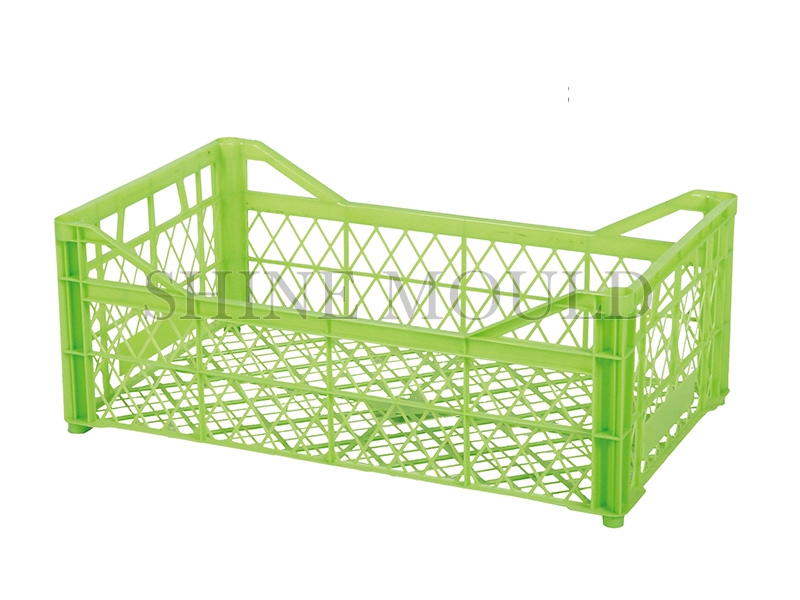

Plastic chairs with armrests and backrests often feature complex lattice structures, perforations, or ergonomic curves to enhance comfort and reduce material usage. The Armchair Mould must accommodate these features without compromising flow or causing incomplete filling. Designers often use flow simulation software to predict how molten plastic will behave within the cavity. Proper placement of gates and careful management of flow paths are essential to ensure that the molten material reaches every intricate feature before it solidifies.

Material Selection and Its Impact on Wall Thickness

The choice of plastic material directly affects wall thickness considerations. Materials such as polypropylene (PP), high-density polyethylene (HDPE), and glass-fiber reinforced plastics each have different flow characteristics, shrinkage rates, and cooling behaviors. The Armchair Mould must be designed with these material properties in mind. For example, PP tends to shrink more than HDPE, so designers may need to adjust wall thickness or add localized thickening to prevent warpage. Reinforced plastics may require slightly thicker walls in high-stress areas to maintain durability over the chair’s lifespan.

Optimizing Cooling and Ejection Systems

Proper wall thickness and cavity design also influence cooling and ejection efficiency. Thick sections can trap heat, causing uneven cooling and longer cycle times. Strategically placed cooling channels in the mould help maintain uniform temperature distribution, reducing the risk of defects. Draft angles and surface treatments on cavity walls also facilitate smooth ejection, reducing the chance of deformation or surface imperfections when the chair is removed from the mould.

Balancing Aesthetics, Strength, and Cost

Ultimately, designing an Armchair Mould involves balancing aesthetics, strength, and production cost. Wall thickness must be sufficient to provide durability, yet optimized to reduce material usage and cycle time. Cavity design should capture the desired ergonomic and visual characteristics while ensuring manufacturability. Iterative design, simulation, and prototyping are essential to achieving this balance, resulting in a chair that meets functional, safety, and visual expectations.

For plastic chairs featuring armrests and backrests, the Armchair Mould’s cavity design and wall thickness control are critical to successful production. Uniform wall thickness, precise cavity geometry, careful material selection, and efficient cooling all contribute to structural stability, aesthetic quality, and production efficiency. Attention to these design considerations ensures the final product delivers both comfort and durability, while reducing manufacturing defects and costs.

Search...

Search... English

English

.jpg)

.jpg)