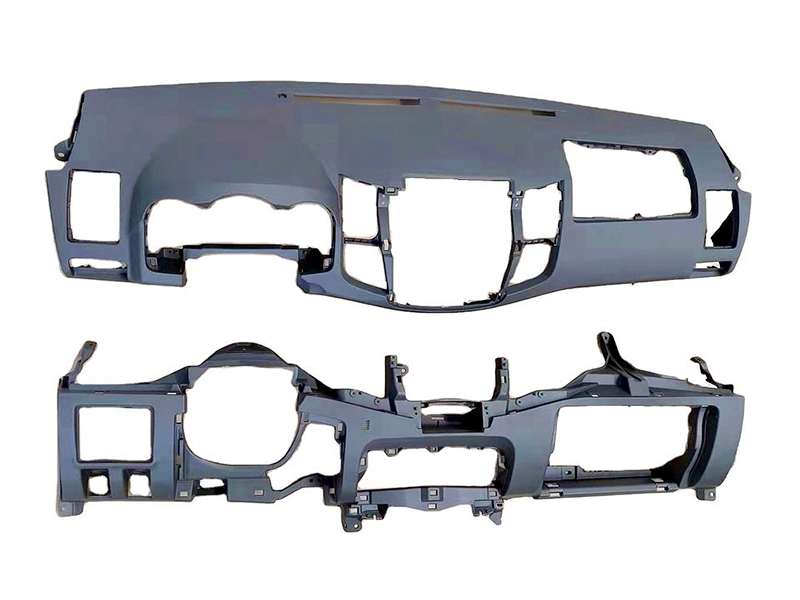

Designing Efficient Venting Systems in Armchair Mould for Large Products

Proper venting is crucial to ensure high-quality results. Air trapped inside the mould during injection can cause defects such as gas porosity, burn marks, and incomplete filling. For complex structures like armchairs, where thickness varies and internal cavities are common, designing an effective venting system is essential. Armchair Mould must allow air and gases to escape efficiently without compromising the structural integrity or aesthetics of the final product. Poor venting can increase scrap rates, reduce mechanical strength, and cause costly rework.

Understanding Air Flow in Large Molds

Large products pose unique challenges for air evacuation. When molten plastic is injected, air initially trapped in corners or deep cavities must find a clear path to escape. Inadequate venting can cause air pockets, which result in surface blemishes or internal voids. The flow of air is influenced by mould geometry, injection speed, and the viscosity of the plastic. Engineers must analyze the mould design carefully to identify potential air traps and incorporate venting channels at strategic locations to ensure uniform evacuation of gases.

Vent Placement Strategies

The placement of vents in an Armchair Mould is critical for effective air release. Vents should be located at further points from the gate, where air is likely to accumulate. Corners, ribs, and thick sections are typical areas prone to air entrapment. Incorporating fine vent slots along these areas allows gases to escape gradually during filling, reducing the risk of burn marks or voids. Proper vent placement also ensures that the molten plastic flows uniformly, improving filling consistency and overall part quality.

Vent Size and Design

The size and design of vent channels must balance airflow with plastic retention. Too small vents may become clogged or fail to release sufficient air, while overly large vents can allow molten plastic to seep out, causing flash. Suitable vent dimensions depend on the plastic material, injection pressure, and mould thickness. Engineers often use simulation tools to model air evacuation and identify the ideal vent size for specific sections of the mould. Additionally, vents may be angled or tapered to prevent backflow and promote smooth escape of gases during the injection cycle.

Material Considerations and Surface Finish

The material of the mould and its surface finish also affect venting performance. Polished or coated surfaces can reduce friction and allow trapped air to escape more easily. In Armchair Molds made for large products, maintaining consistent surface quality across all cavities is important to prevent air from being trapped in micro-gaps. Using high-quality steel with precision machining ensures that vent channels remain effective throughout multiple production cycles, reducing wear and maintaining consistent part quality.

Testing and Iterative Optimization

Even with careful design, practical testing is necessary to validate venting performance. Trial runs can reveal areas where air is trapped, which may not be apparent in theoretical models. Adjustments, such as adding additional vent slots or modifying vent orientation, can improve air evacuation. Iterative testing and optimization help ensure that large armchair components are free from gas porosity, enhancing both aesthetic appeal and structural integrity. Continuous monitoring and feedback during production further refine the venting system for consistent quality.

Designing an efficient venting system in Armchair Mould for large products is essential to reduce gas porosity and other injection-related defects. Proper vent placement, suitable channel design, material selection, and iterative testing all contribute to effective air evacuation. By addressing these factors, manufacturers can produce high-quality, defect-free armchair components, improving both performance and visual appeal while reducing waste and rework in large-scale production.

Search...

Search... English

English