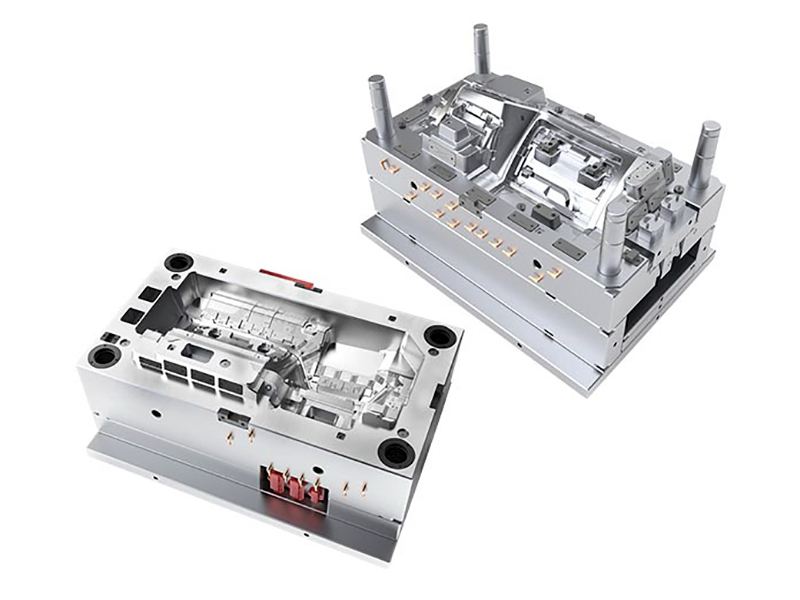

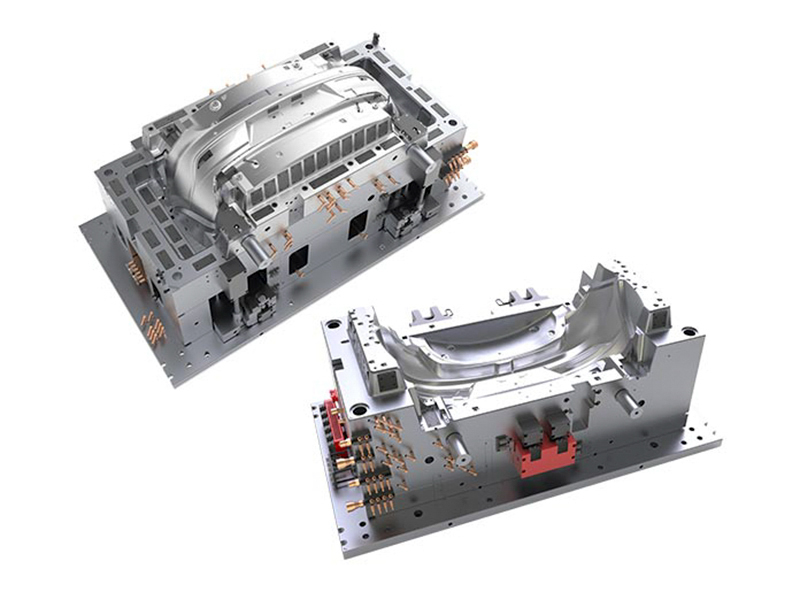

Effects of Surface Treatment on Basket Mould Demolding Performance

Surface treatment plays a crucial role in the performance and longevity of the Basket Mould used in manufacturing. Techniques such as polishing and electroplating are commonly applied to improve the surface quality, reduce friction, and enhance resistance to wear and corrosion. For moulds used in producing complex products, surface characteristics can directly affect the ease of demolding and the quality of the finished product. Understanding how these treatments influence mould behavior is essential for optimizing production efficiency and reducing defects.

Polishing and Its Influence on Demolding

Polishing is one of the common surface treatment techniques applied to moulds. By removing surface irregularities and creating a smooth, even finish, polishing reduces the adhesion between the mould and the material being shaped. This smooth surface allows for easier release of the product, reducing the need for excessive force during demolding. Additionally, a polished surface helps prevent the accumulation of residues or material buildup, which can otherwise cause defects or sticking. The quality of polishing, including the uniformity and degree of smoothness, determines how effectively the mould facilitates product release.

Electroplating and Surface Hardness

Electroplating involves coating the mould surface with a thin layer of metal, such as nickel or chromium, to improve hardness, wear resistance, and corrosion protection. This treatment enhances the durability of the mould, allowing it to withstand repeated use without surface degradation. A harder surface also maintains consistent dimensional accuracy, ensuring that demolding is predictable and smooth. Electroplating can reduce surface friction when combined with proper polishing, further improving demolding performance. However, any irregularities in the plating layer or improper adhesion can create rough areas, which may hinder product release or even damage delicate materials during demolding.

Impact on Product Quality and Production Efficiency

Surface treatment not only affects the mould itself but also the quality of the final product. Smooth, well-treated surfaces prevent marks, scratches, or uneven textures on the molded material. This is especially important for high-precision components or products with aesthetic requirements. Improved demolding efficiency reduces cycle times, lowers the risk of material damage, and decreases labor or mechanical intervention. Over time, the benefits of surface treatment translate into reduced maintenance costs and fewer rejected products, making it a crucial step in mould preparation.

Considerations for Optimizing Surface Treatment

To improve the positive impact on demolding performance, it is important to consider both the type of surface treatment and the material of the mould. Different alloys respond differently to polishing and electroplating, and selecting the right combination is key to achieving desired results. Regular inspection and maintenance are necessary to ensure that the treated surface retains its effectiveness, as wear or corrosion over time can compromise demolding performance. Manufacturers may also experiment with advanced coatings or hybrid treatments to further enhance mould release properties without affecting durability.

Surface treatment, including polishing and electroplating, significantly influences the demolding performance of moulds. Smooth, hard, and well-maintained surfaces reduce friction, improve release efficiency, and ensure consistent product quality. Attention to proper surface treatment techniques and ongoing maintenance ensures that moulds, including Basket Moulds, perform reliably and efficiently throughout their service life. By understanding and optimizing these treatments, manufacturers can achieve better production outcomes while reducing downtime and material waste.

Search...

Search... English

English