Efficient Cooling System Design for Dustbin Mould Production

Introduction to Cooling Challenges in Dustbin Moulds

A Dustbin Mould is typically used to manufacture large, thick-walled plastic products that must withstand repeated mechanical stress and outdoor exposure. Compared with smaller household items, plastic dustbins have longer cooling times due to their size, uneven wall thickness, and high material volume. As a result, cooling system design becomes one of the critical factors affecting production efficiency. An optimized cooling system not only shortens cycle time but also improves dimensional stability, surface quality, and overall mould lifespan.

Role of Cooling in Injection Molding Efficiency

In injection molding, cooling accounts for a large portion of the total cycle time. Once molten plastic fills the cavity, it must cool and solidify sufficiently before ejection. If cooling is inefficient, the mould remains closed longer, reducing output and increasing energy consumption. For dustbin products, improper cooling can also cause warpage, sink marks, or internal stress. A well-designed cooling system ensures uniform heat removal, enabling faster cycles without compromising product quality.

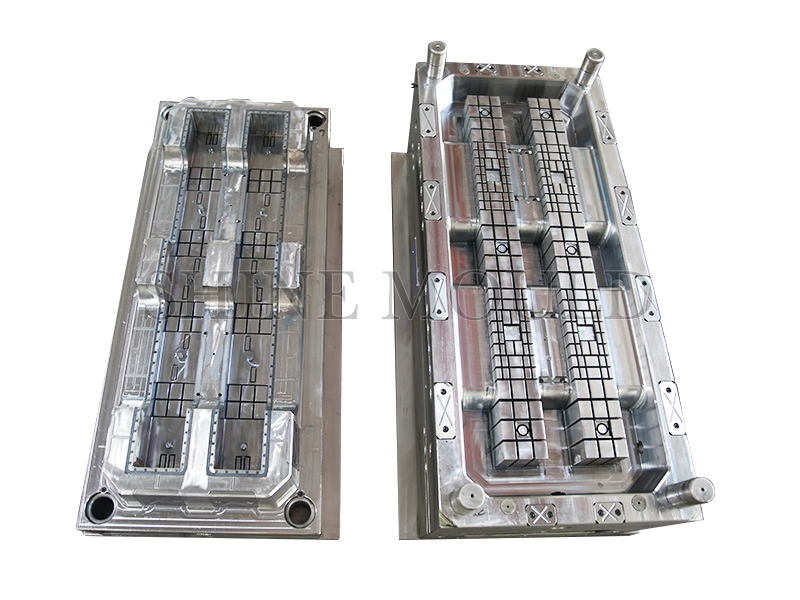

Strategic Cooling Channel Layout

The layout of cooling channels is the foundation of an efficient cooling system. Channels should be positioned as close as possible to the cavity surface while maintaining mould strength. In dustbin moulds, areas such as the bottom, corners, and thick rib sections require special attention because they retain heat longer. By following the contour of the cavity and maintaining consistent spacing, cooling channels can remove heat evenly across the entire product. This approach reduces temperature differences that often cause deformation or uneven shrinkage.

Balancing Cooling for Thick-Walled Structures

Dustbins usually feature varying wall thicknesses to enhance strength and durability. These variations make balanced cooling more challenging. Thicker sections cool more slowly and may become hotspots if not properly addressed. Designing additional cooling lines or localized cooling zones for these areas helps equalize cooling time across the part. Balanced cooling ensures that all sections of the dustbin solidify at a similar rate, which significantly improves dimensional accuracy and shortens overall cycle time.

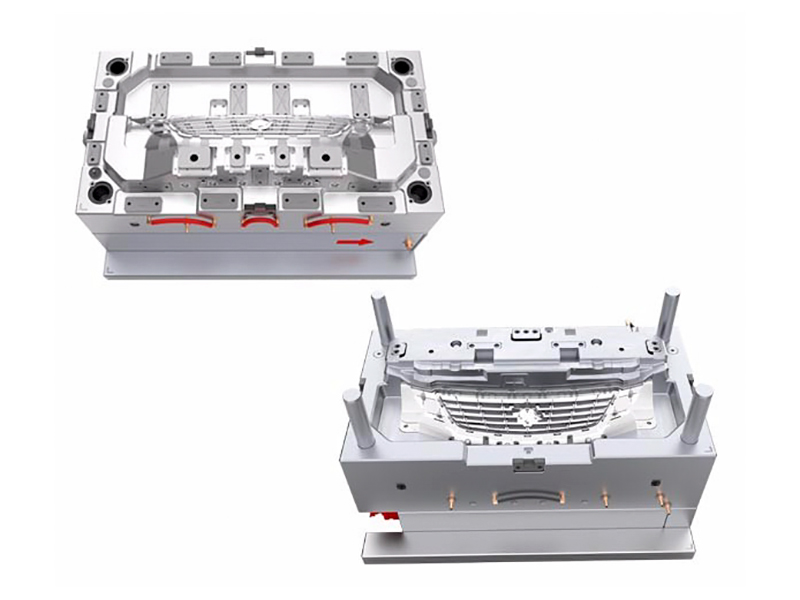

Selection of Cooling Methods and Media

Choosing the appropriate cooling method is essential for improving efficiency. Traditional straight-drilled cooling channels are widely used, but for complex dustbin shapes, advanced solutions such as baffle cooling or spiral channels can be more effective. Water is commonly used as the cooling medium due to its high heat capacity, but flow rate and temperature must be carefully controlled. Stable coolant circulation enhances heat transfer efficiency and maintains consistent mould temperature throughout continuous production.

Integration with Mould Material and Surface Design

The effectiveness of a cooling system is also influenced by the mould material and surface treatment. High-thermal-conductivity mould steels improve heat transfer from the cavity to the cooling channels. In addition, smooth internal channel surfaces reduce flow resistance and improve cooling efficiency. Coordinating cooling design with mould material selection allows heat to dissipate more rapidly, directly contributing to reduced cycle times and increased production output.

Impact on Productivity and Mould Longevity

An optimized cooling system improves not only short-term productivity but also long-term mould performance. Uniform temperature distribution reduces thermal stress within the mould, reducing the risk of cracking or deformation over time. Faster cooling cycles increase daily production capacity, lower energy costs, and improve return on investment. For manufacturers producing large volumes of dustbins, efficient cooling design becomes a key competitive advantage.

Designing an efficient cooling system is essential for improving the performance of a Dustbin Mould. By optimizing cooling channel layout, addressing thick-walled sections, selecting suitable cooling methods, and coordinating with mould materials, manufacturers can significantly reduce cycle time while maintaining product quality. A well-engineered cooling system ensures stable production, higher efficiency, and longer mould life, making it a critical element in successful dustbin injection molding operations.

Search...

Search... English

English