Enhancing Operator Safety and Ergonomics in Package Mould Design

The Importance of Ergonomics in Mould Operations

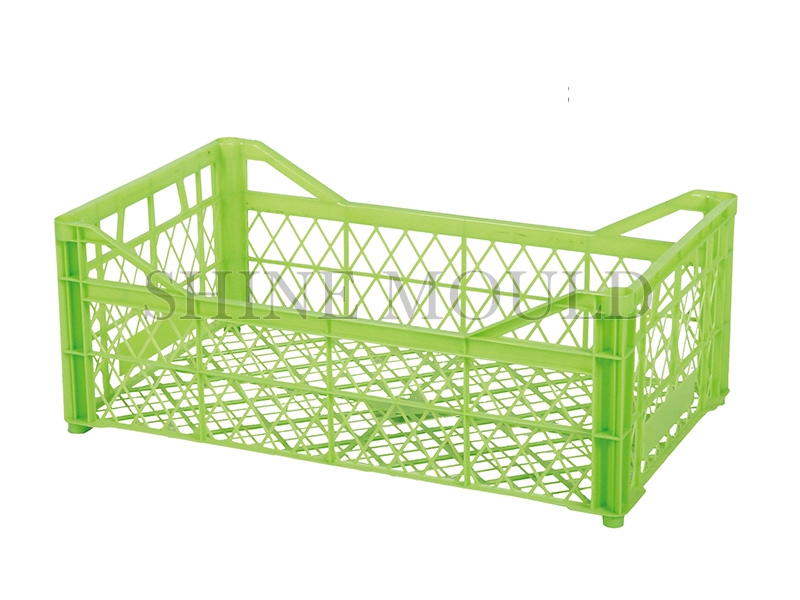

In packaging manufacturing, the design of a package mould extends beyond product quality and efficiency. Ensuring operator safety and comfort is equally essential, particularly in high-volume or high-pressure production environments. Ergonomically designed moulds reduce physical strain, minimize the risk of injuries, and enhance operational efficiency. Considering human factors during the design phase of a Package Mould is critical for fostering a safe workplace while maintaining consistent production performance.

Ergonomic Design Features

Ergonomically optimized moulds focus on reducing repetitive strain and awkward postures during setup, operation, and maintenance. Features such as accessible handles, lightweight modular components, and strategically positioned locking mechanisms allow operators to interact with the mould safely and efficiently. Proper alignment of the mould in the press or injection machine also reduces bending, reaching, or twisting motions that can cause fatigue or musculoskeletal disorders. By incorporating these ergonomic principles, manufacturers can improve productivity and reduce absenteeism due to work-related injuries.

Safety Considerations in Package Mould Design

Safety is a fundamental aspect of mould design. High temperatures, hydraulic or mechanical pressure, and moving components can pose hazards to operators. Package Moulds should include protective features such as safety guards, interlocks, and secure locking systems to prevent accidental contact with hot or moving parts. Clearly marked surfaces and warning labels further enhance safety awareness during operation. Additionally, quick-release mechanisms or guided inserts can reduce the time operators spend in potentially hazardous positions, minimizing risk exposure.

Maintenance and Ease of Handling

Maintenance and routine cleaning are also critical factors impacting safety and ergonomics. Moulds that are cumbersome or require awkward postures for disassembly increase the likelihood of operator strain or accidents. Designing moulds with modular inserts, standardized interfaces, and lightweight components allows easier handling and safer maintenance procedures. Ergonomic considerations in this phase not only protect operators but also reduce downtime, ensuring continuous production without compromising safety or quality.

Training and Operator Awareness

Even with ergonomically designed and safe moulds, proper training is essential. Operators should understand the correct procedures for handling, installing, and maintaining the mould. Awareness of potential hazards and the use of personal protective equipment (PPE) further reduce risk. Integrating ergonomic and safety considerations into standard operating procedures ensures that the design benefits are fully realized in practice.

Benefits of Ergonomic and Safe Moulds

Investing in ergonomically designed and safety-conscious package moulds offers multiple advantages. Reduced physical strain enhances operator comfort and morale, while minimizing injury risk decreases downtime and healthcare costs. Improved handling efficiency causes faster setup and maintenance, contributing to overall production performance. Additionally, a safe work environment aligns with regulatory compliance and corporate social responsibility, enhancing the company’s reputation and fostering a culture of safety.

Prioritizing Operator Well-Being in Mould Design

Considering human ergonomics and safety in the design of Package Moulds is essential for modern manufacturing operations. Features that reduce physical strain, prevent accidental injuries, and facilitate safe maintenance improve both operator well-being and production efficiency. By integrating ergonomic principles, protective mechanisms, and proper training, manufacturers can create mould systems that balance performance with safety, ultimately supporting sustainable and high-quality packaging production.

Search...

Search... English

English