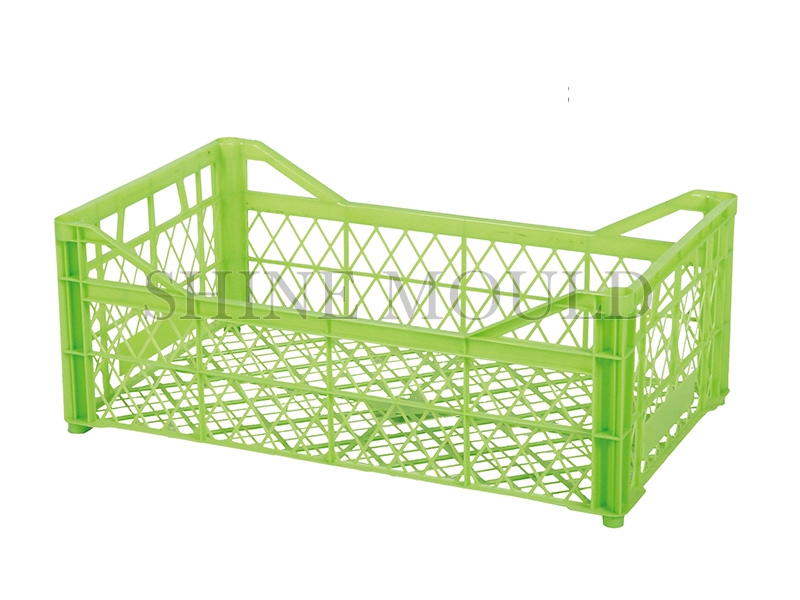

Evaluating the Suitability of Crate Mould for Multi-Cavity Production

Multi-cavity moulding is a widely used technique to increase production efficiency and reduce cycle time. For products like storage crates, which are produced in large volumes, the ability to produce multiple units simultaneously can significantly lower production costs. However, not all moulds are equally suitable for multi-cavity production. The design, material properties, and precision of the mould play a critical role in determining whether high-quality, consistent parts can be achieved. Crate Mould, commonly used in the production of plastic crates, must meet several technical requirements to be viable for multi-cavity applications.

Structural Considerations of the Mould

The structural design of the Crate Mould is a fundamental factor in its suitability for multi-cavity production. A multi-cavity mould requires uniform distribution of molten plastic to each cavity to ensure consistent part quality. This demands precise engineering of the runner and gate system, as well as proper venting to prevent air entrapment. The mould must also maintain dimensional stability under the high pressures generated during injection. Any deformation or misalignment can result in defective parts, uneven wall thickness, or surface imperfections. Therefore, a well-engineered Crate Mould with reinforced plates and accurate alignment systems is essential for reliable multi-cavity operation.

Material and Durability Requirements

Material selection and durability are crucial when using a Crate Mould for multi-cavity production. Multi-cavity operations subject the mould to higher stress and repeated thermal cycling. High-quality tool steel or alloy materials with good wear resistance and thermal conductivity are preferred. These materials help maintain cavity integrity over prolonged production runs and ensure uniform heat distribution. Proper surface treatment, such as nitriding or polishing, can also enhance the mould’s resistance to wear and corrosion. By selecting durable materials, manufacturers can prevent premature mould failure and reduce downtime caused by maintenance or repairs.

Process Control and Consistency

Even a well-designed Crate Mould requires precise process control to function effectively in multi-cavity production. Injection pressure, temperature, and cooling rates must be carefully balanced to guarantee consistent filling across all cavities. Variations in these parameters can cause differences in part weight, dimensions, or mechanical properties. Advanced manufacturing systems often use sensors and automated controls to monitor and adjust processing conditions in real time. Ensuring uniformity in each cavity is critical for producing crates that meet strict quality standards and decrease waste.

Economic Considerations

The cost implications of using a Crate Mould for multi-cavity production are also significant. While multi-cavity moulds can greatly increase output, they require a higher initial investment in design, materials, and maintenance. Manufacturers must evaluate the balance between upfront costs and long-term productivity gains. In high-volume production scenarios, the efficiency improvements and reduced per-unit costs often justify the initial investment. However, for smaller production runs, the complexity and cost of a multi-cavity mould may not be economically viable.

Crate Mould can be highly suitable for multi-cavity production if certain conditions are met. Proper structural design, durable materials, precise process control, and careful economic evaluation are all essential for successful implementation. When these factors are addressed, multi-cavity moulding can significantly enhance productivity, ensure consistent quality, and reduce production costs for large-scale crate manufacturing. Conversely, inadequate design or process management may result in defects and operational inefficiencies, highlighting the importance of thorough planning and engineering expertise in multi-cavity applications.

Search...

Search... English

English

.jpg)