How Cavity Count Influences Bucket Mould Production Efficiency

In plastic injection molding, production efficiency is closely linked to mould design choices, among which cavity count plays a decisive role. For manufacturers producing plastic buckets at scale, determining the appropriate number of cavities is a strategic decision that affects output volume, cycle time, equipment utilization, and overall cost. A well-planned Bucket Mould balances cavity quantity with machine capability and process stability, allowing manufacturers to meet demand without compromising product quality or operational reliability.

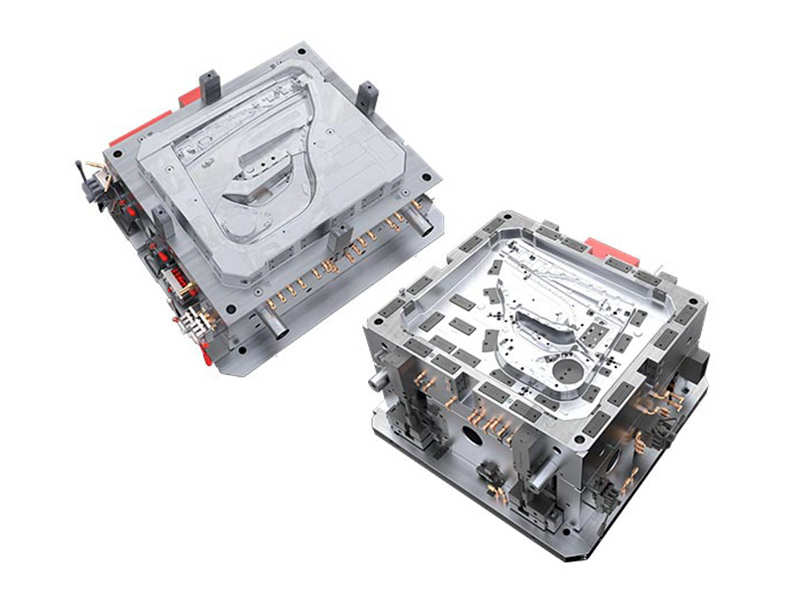

Understanding What Cavity Count Means

Cavity count refers to the number of identical product impressions within a mould. A single-cavity mould produces one bucket per cycle, while a multi-cavity mould produces several buckets simultaneously. Increasing the number of cavities theoretically increases output per cycle, but in practice, the relationship between cavity count and efficiency is more complex. Factors such as injection pressure, cooling capacity, clamping force, and material flow behavior all influence whether higher cavity counts truly improve productivity.

Machine Compatibility and Clamping Force

As cavity count increases, so does the total projected area and injection pressure required to fill all cavities evenly. This places greater demands on the injection molding machine, particularly in terms of clamping force and injection capacity. If the machine is undersized, issues such as short shots, flash, or uneven wall thickness may occur. To achieve suitable efficiency, the Bucket Mould cavity count must be matched carefully with the machine’s specifications, ensuring stable operation without excessive stress on equipment.

Material Flow Balance and Quality Consistency

Production efficiency is not only about quantity but also about consistent quality. In multi-cavity moulds, balanced runner systems are critical to ensure uniform filling of all cavities. Poor balance can result in variation between buckets produced in the same cycle, causing rejects and reduced effective output. A well-engineered mould ensures that material flow, pressure, and temperature are evenly distributed, maintaining product consistency while improving efficiency.

Tooling Cost Versus Productivity Gains

Increasing cavity count also affects tooling investment. Multi-cavity moulds are more complex to design and manufacture, causing higher initial costs. However, for high-volume production, these costs are often offset by reduced labor per unit, lower energy consumption per product, and faster order fulfillment. Manufacturers must evaluate production volume forecasts to determine whether the productivity gains of a higher cavity count justify the increased tooling expense.

Maintenance and Operational Considerations

Higher cavity counts can influence maintenance requirements and downtime. More cavities mean more surfaces, cooling channels, and ejection components that require regular inspection and upkeep. If maintenance is neglected, efficiency gains can be lost due to increased stoppages or inconsistent output. Proper maintenance planning ensures that a high-cavity Bucket Mould continues to operate efficiently throughout its service life.

Scalability and Production Flexibility

Cavity count also affects production flexibility. Lower cavity moulds may offer greater adaptability for product changes or smaller batch runs, while higher cavity moulds are ideal for standardized, long-term production. Selecting the right cavity count allows manufacturers to scale production efficiently while aligning with market demand and operational strategy.

The number of cavities in a Bucket Mould has a significant impact on production efficiency, influencing output capacity, cycle time, machine requirements, and overall cost structure. While higher cavity counts can dramatically increase productivity, they also demand careful consideration of machine capability, cooling efficiency, material flow balance, and maintenance planning. By selecting an appropriate cavity count based on production goals and technical constraints, manufacturers can achieve a balanced and efficient molding process that supports both quality and profitability.

Search...

Search... English

English

.jpg)

.jpg)

.jpg)