How to Clean Package Mold

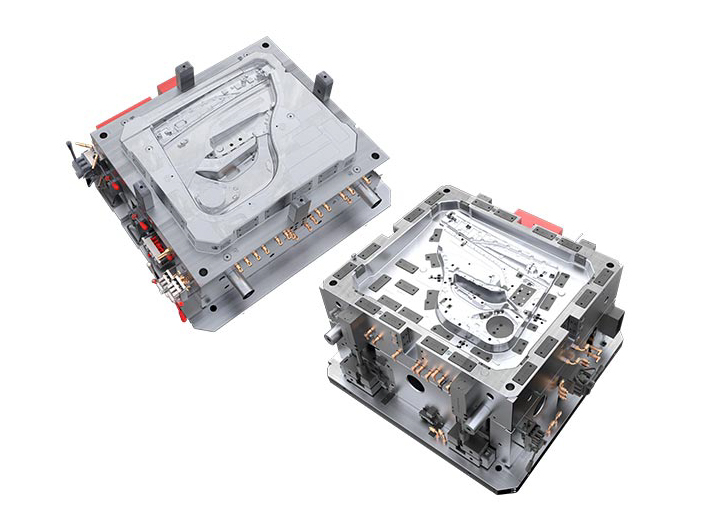

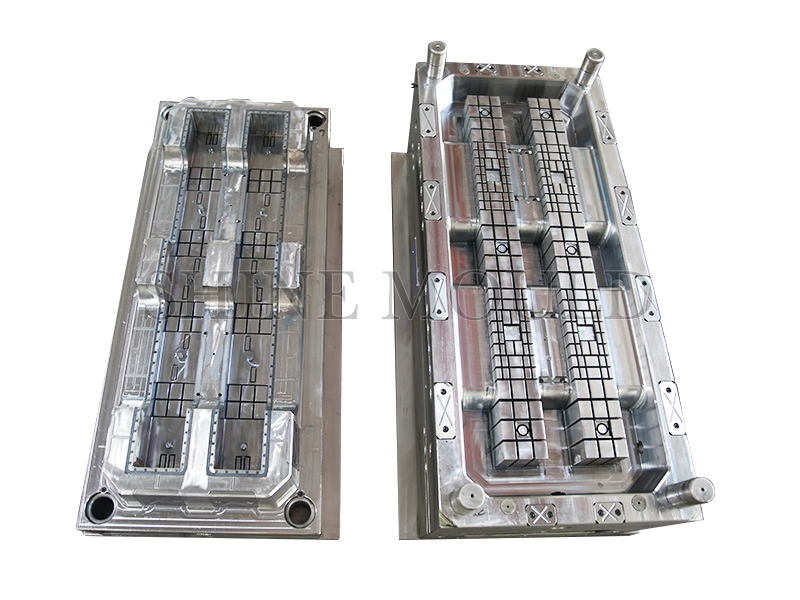

Cleaning package molds is essential for maintaining their quality and prolonging their lifespan. Package molds, also known as packaging molds, are used in the manufacturing of various types of packaging, such as plastic containers, bottles, and caps. Proper cleaning ensures that the molds remain free from residue, debris, and contaminants, preventing defects in the final products and ensuring efficient production. Here's a comprehensive guide on how to clean package molds effectively:

Before starting the cleaning process, prioritize safety. Wear appropriate personal protective equipment (PPE), such as gloves and safety glasses, to protect yourself from any chemicals or debris that may be present in the molds.

If the package mold is designed for easy disassembly, take it apart following the manufacturer's instructions. Disassembling the mold allows for more thorough cleaning, especially in hard-to-reach areas.

Use a brush or compressed air to remove loose residue, debris, or excess material from the mold surfaces. Pay close attention to corners, grooves, and intricate details where debris may accumulate.

Solvent cleaning is commonly used to dissolve and remove contaminants like oils, grease, and mold release agents. Select a suitable solvent based on the type of material used in the mold, such as isopropyl alcohol or a mild detergent solution. Apply the solvent with a soft cloth or brush to clean the mold surfaces thoroughly.

For stubborn residues, mechanical cleaning methods can be effective. Nylon brushes, scrapers, or cleaning pads can be used to gently scrub the mold surfaces, taking care not to damage or scratch them.

Ultrasonic cleaning is a powerful and efficient method for cleaning package molds. It involves immersing the molds in an ultrasonic cleaning solution and subjecting them to high-frequency vibrations. The vibrations create tiny bubbles that dislodge and remove contaminants from the mold surfaces.

Steam cleaning is another effective method for removing tough residues from package molds. The high-pressure steam helps dislodge and dissolve contaminants, leaving the molds clean and sanitized.

After cleaning the package molds, rinse them thoroughly with clean water to remove any remaining cleaning agents or residues. Ensure that all traces of solvents or detergents are washed away.

Proper drying is crucial to prevent moisture-related issues like corrosion or mold growth. Allow the molds to air dry or use compressed air to remove excess water from the mold surfaces.

Reassemble the mold and apply a suitable mold release agent or lubricant, as recommended by the manufacturer. Lubrication ensures smooth mold operation and prevents the sticking of the molded parts.

Before putting the package molds back into production, inspect them carefully for any signs of damage, wear, or lingering contaminants. Address any issues promptly to maintain the mold's performance and product quality.

Implement a preventive maintenance schedule for the package molds. Regularly clean and inspect the molds to address any potential problems early on and extend their lifespan.

Cleaning package molds is a crucial aspect of maintaining their quality and ensuring the efficient production of packaging materials. From solvent cleaning to ultrasonic and steam cleaning, there are various methods available for different types of molds and levels of contamination. By following proper cleaning procedures and preventive maintenance practices, manufacturers can maximize the lifespan of their package molds and produce high-quality packaging materials consistently.

Search...

Search... English

English

.jpg)

.jpg)