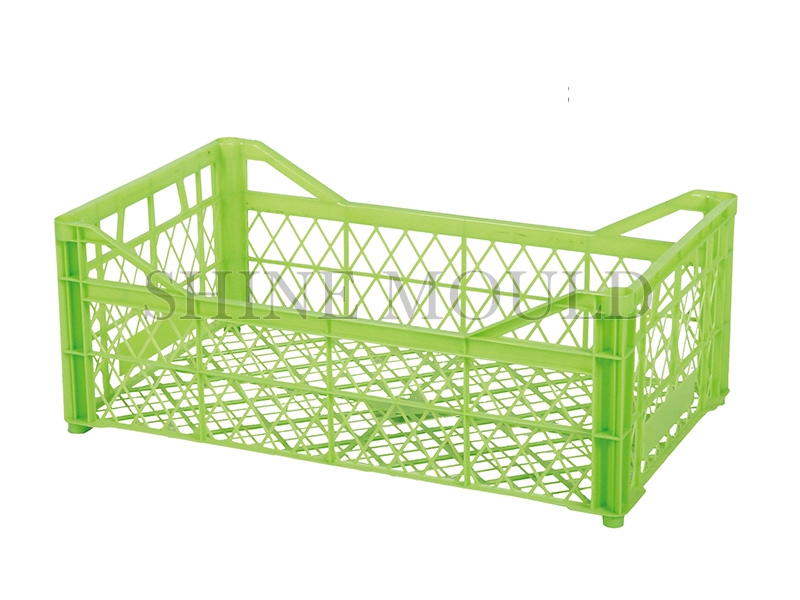

How To Maintain The Basket Mold To Prolong Its Service Life?

Maintaining and caring for a basket mold is essential to ensure its longevity and consistent performance in the production of plastic baskets. Proper maintenance practices can help prevent mold damage, reduce downtime, and extend the mold's lifespan.

1. Regular Cleaning:

Regularly clean the mold to remove residual plastic, dirt, and contaminants that can accumulate during the production process. Use a soft brush or compressed air to remove loose particles. For stubborn residues, consider using a mild solvent or cleaning agent compatible with the mold material. Ensure that the mold is completely dry before storage.

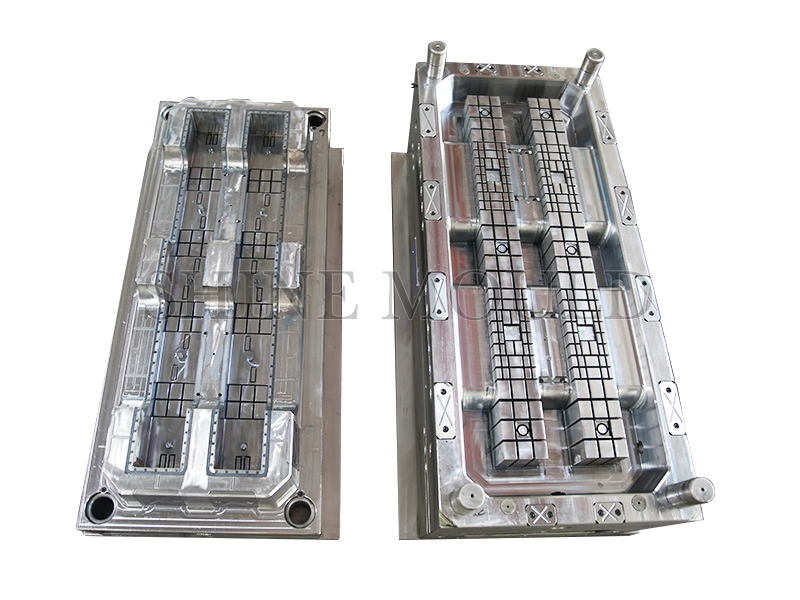

2. Inspection and Lubrication:

Conduct a thorough inspection of the mold components, including the core, cavity, sliders, ejector pins, and cooling channels. Look for signs of wear, damage, or rust. Lubricate moving parts with a suitable mold release agent or lubricant to reduce friction and prevent corrosion. Apply a rust inhibitor to exposed metal surfaces if needed.

3. Preventive Maintenance Schedule:

Establish a preventive maintenance schedule for the basket mold. Create a checklist of tasks to be performed regularly, such as cleaning, lubrication, and inspection. The frequency of maintenance will depend on the production volume and environmental conditions in your facility but should generally be done at least after every production run.

4. Monitor Cooling System:

Ensure that the cooling channels are free from blockages and are functioning correctly. Blocked or inefficient cooling can lead to uneven cooling of the mold, which can result in warping or other defects in the plastic baskets. Clean the cooling channels and check for any leaks.

5. Store Properly:

When the basket mold is not in use, store it in a dry, clean, and temperature-controlled environment. Protect the mold from dust, moisture, and direct sunlight. Consider using mold covers or protective coatings to prevent oxidation and corrosion of metal parts.

6. Handle with Care:

When handling the mold, use appropriate lifting equipment and ensure that it is not dropped or subjected to excessive force. Mishandling can lead to damage, especially in delicate mold components.

7. Address Minor Repairs Promptly:

If you notice any minor damage or wear during inspections, address it promptly. Minor repairs can prevent more extensive damage in the long run. Consult with a mold repair specialist if necessary.

8. Maintain Proper Mold Temperature:

Ensure that the mold operates at the appropriate temperature range for the plastic material being used. Excessive heat or cooling can affect the molding process and mold longevity.

9. Avoid Overloading:

Avoid overloading the mold with excessive injection pressure or tonnage. Operating within the specified limits helps prevent stress and damage to the mold components.

10. Document Maintenance Records:

Maintain detailed records of all maintenance activities performed on the mold. Document dates, tasks completed, and any issues identified. This information is valuable for tracking mold performance and scheduling future maintenance.

11. Training and Education:

Train the operators and maintenance personnel on proper mold handling, maintenance, and troubleshooting techniques. Educated personnel can help identify and address issues more effectively.

12. Collaborate with Specialists:

For complex maintenance tasks or major repairs, consider collaborating with mold maintenance specialists or professionals with expertise in mold repair and refurbishment.

13. Monitor Mold Performance:

Continuously monitor the performance of the mold during production runs. Pay attention to the quality of the produced baskets, cycle times, and any signs of mold wear or deterioration. Early detection of issues allows for timely intervention.

By following these maintenance and care guidelines, you can significantly extend the lifespan of your basket mold and ensure consistent, high-quality production of plastic baskets. Proper mold maintenance is an investment in the efficiency and reliability of your manufacturing process.

Search...

Search... English

English