How to use Package Mold

Package molds are used to create packaging materials, such as plastic or paper containers, that are designed to fit specific products. Here are the basic steps to use a package mold:

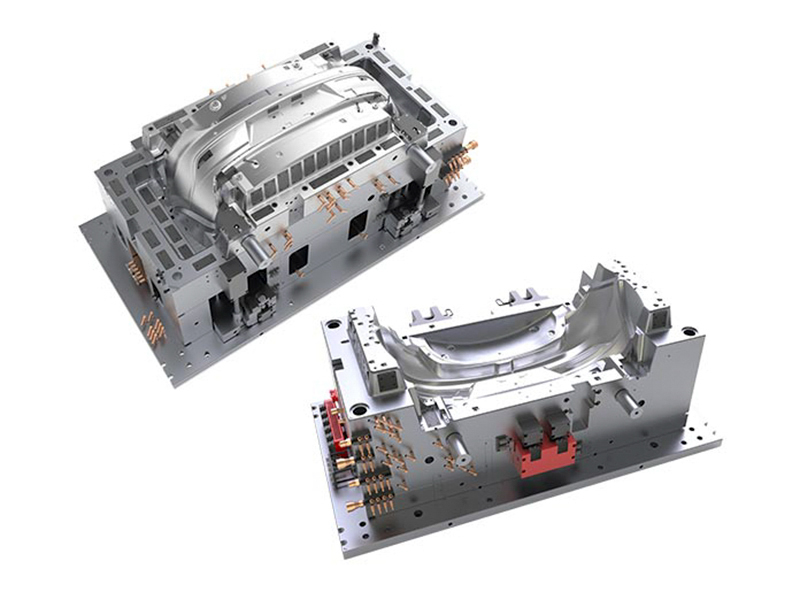

Design the mold: The first step is to design the package mold using computer-aided design (CAD) software or other design tools. The mold must be designed to fit the specific dimensions and shape of the product.

Fabricate the mold: Once the mold design is complete, it needs to be fabricated. This typically involves using a machine tool or CNC router to cut the mold out of a block of metal, such as aluminum or steel.

Install the mold: Once the mold is fabricated, it needs to be installed in a packaging machine. The mold is typically mounted on a machine bed and connected to the machine's hydraulic or pneumatic system.

Load the material: The next step is to load the packaging material into the machine. This can be done manually or automatically, depending on the type of machine.

Run the machine: With the mold installed and the material loaded, the machine is ready to run. The machine will apply heat, pressure, or both to the material, causing it to conform to the shape of the mold and create the desired packaging container.

Remove the finished product: Once the packaging material has cooled and hardened, the finished product can be removed from the mold. This can be done manually or with an automated ejection system.

Overall, using a package mold requires specialized equipment and expertise. It is important to work with a qualified packaging supplier who can design and fabricate molds to meet your specific needs, and who has the machinery and experience to produce high-quality packaging containers.

Search...

Search... English

English