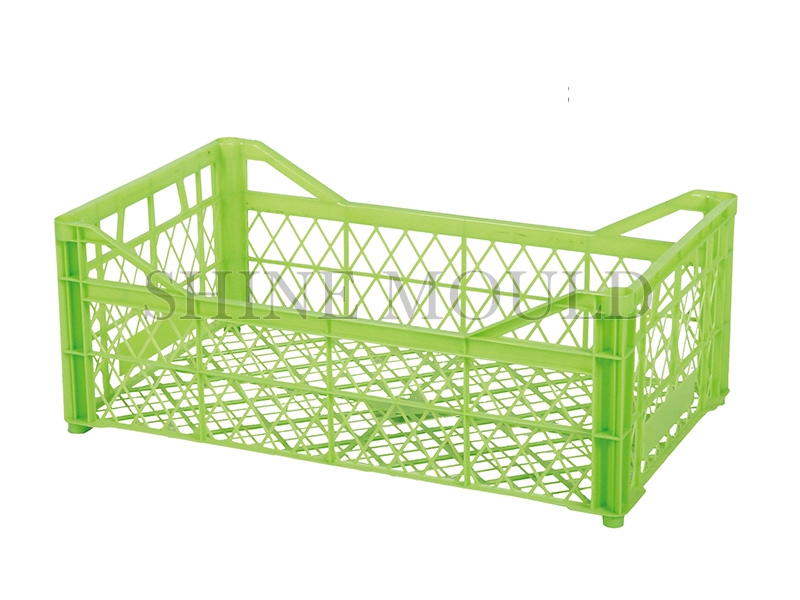

Important Factors Affecting The Quality Of Armchair Mould Throughout Its Life Cycle

Mold manufacturing is a complicated process. From design, processing, assembly, debugging to final use, there are many factors that affect the quality of Armchair Mould throughout its life cycle.

Steel is the decisive factor in determining the quality of the mold. Choosing reasonable steel is the most important factor. The criteria for selecting steel are:

- Requirements for injection molding materials

Different plastics should use different steel materials, such as requirements for high polishing, corrosion resistance, etc.

- Surface treatment

The surface treatment of the mold is also very important. Nitriding can increase the surface hardness of steel and effectively extend the life of the mold. Electroplating can effectively modify die steel. For certain high-brightness and corrosion-resistant plastic mold parts, electroplating can be used to enhance and improve the performance of steel.

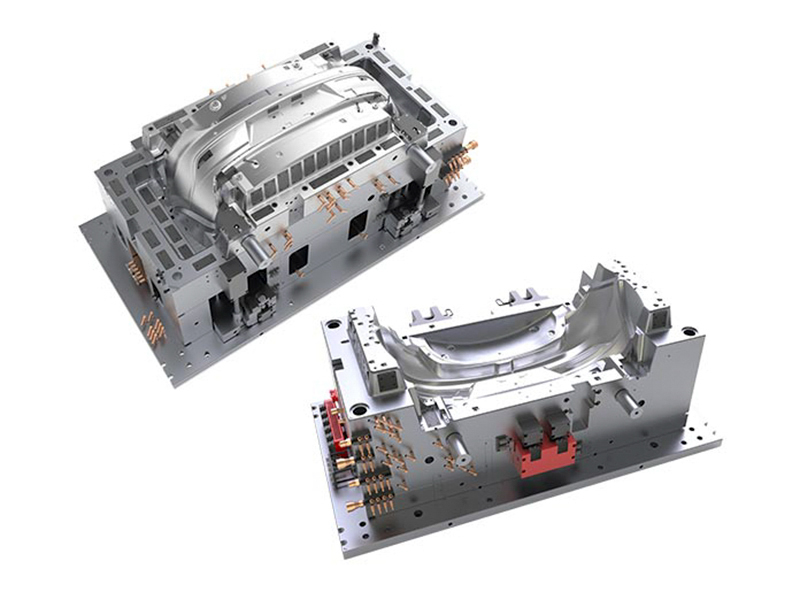

The mature mold structure not only considers the material properties of the product, shrinkage rate, molding temperature, elastic tensile deformation coefficient, etc. but also considers the cooling water channel and the opening and closing speed of the mold. A reasonable mold structure can effectively extend the life of the mold, ensure the stable production of the mold, improve efficiency, and reduce costs.

For workers to be good at doing things, they must first improve their tools. The arrangement of the molding process is particularly important. A reasonable process arrangement can speed up the production cycle, shorten the processing time, and effectively save costs. More importantly, an accurate and reasonable molding process can ensure the stability and life of the mold during the production process. Some machining errors will cause mold welding. Regardless of the quality of the welding, it will cause losses to the mold. In addition, a poor molding process may affect the movement of the mold, shorten the life of the mold, cause the mold to break, or even break during the production process.

The experience of mold assemblers is not conducive to seemingly simple work, but it is the most technical work. The main work related to complex molds is this work. The flat mold is the simplest, and as long as there is no flash, the fractal surface is basically fine. It is very troublesome for auto parts molds. The fractal surface is not only relatively irregular but also usually includes multiple sliders and top blocks. At the same time, it can improve and perfect other problems of the mold through touch, so it is a comprehensive work.

Anyone with mold experience knows the importance of cooling to molds. Due to the increase in prices and labor wages, it is unimaginable to reduce the profit of the one-second injection cycle in the mass production of products. However, when the production cycle is accelerated, the temperature of the mold will rise. If the mold cannot be controlled effectively, the mold will become too hot to form, and even deformed molds will be scrapped. Therefore, excellent waterway design is especially important, including the layout density, diameter, connection between the waterways, and so on.

Mold maintenance is mainly maintenance during the production process. The mold is like a car. If it is not used for a long time without maintenance, it may cause the mold to be scrapped. Therefore, every time the mold is used, it must be fully maintained, especially the rust prevention of the plastic mold parts and the rust prevention of the main moving parts. Since the mold must be watered during the production process, it may fall into the mold during installation or disassembly, so please make sure that the mold is dry before applying an oil-repellent layer.

Search...

Search... English

English