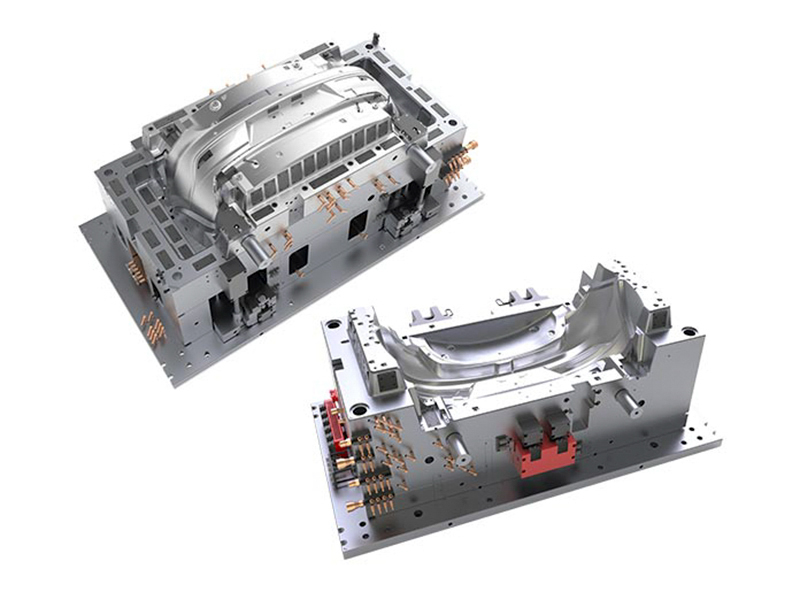

Influence of Complex Crate Mould Structures on Product Stability

The design of a mould plays a fundamental role in determining the quality and durability of injection-molded products. Crate Moulds with complex structures are widely used in manufacturing crates, containers, and other hollow products that require both strength and stability. These moulds often include intricate internal supports, ribs, and undercuts, which can enhance the mechanical performance of the final product. However, the very complexity that provides structural advantages also introduces challenges in terms of material flow, cooling uniformity, and dimensional precision, all of which can influence the product’s final properties.

Impact on Product Strength

Complex mould geometries directly affect the distribution of material within the molded item. Features such as reinforcing ribs and thicker wall sections can significantly increase the structural integrity of crates by resisting bending and impact forces. Properly designed internal structures help distribute load more evenly, preventing weak points that could cause premature failure. Conversely, poorly designed or unevenly filled areas can result in stress concentrations, reducing strength and causing warping or cracking under mechanical load. The precision of the mould design is therefore critical in ensuring that the product achieves the desired performance characteristics.

Influence on Dimensional Stability

The stability of injection-molded products is closely tied to how consistently the mold allows material to flow and cool. Complex Crate Moulds may have areas that cool faster or slower than others due to variations in thickness or intricate features. Uneven cooling can cause internal stresses and shrinkage, affecting dimensional accuracy and potentially causing deformation after demolding. Optimizing the design of cooling channels, as well as selecting appropriate processing parameters, is essential to decrease these effects and maintain the product’s geometric stability over time.

Challenges in Material Flow

Intricate mould structures can complicate the flow of molten plastic during injection. Areas with sharp corners, deep recesses, or narrow channels may experience incomplete filling or air entrapment, which negatively impacts both strength and surface quality. Flow simulation tools and careful gate placement are commonly employed to predict and correct potential issues, ensuring that the molten material fills the complex mould evenly. A well-balanced flow pattern reduces the risk of weak spots and enhances the overall performance of the finished crate.

Maintenance and Longevity Considerations

Complex Crate Moulds require careful maintenance to sustain consistent product quality. Wear, scratches, or residue buildup in intricate sections can compromise both strength and stability, causing defects in subsequent production cycles. Regular cleaning, inspection, and precise alignment of mould components are necessary to preserve the intended structural advantages and ensure reproducible results across large production volumes.

The use of complex Crate Moulds has a profound impact on the strength and stability of injection-molded products. While intricate designs provide significant mechanical benefits, they also introduce challenges related to material flow, cooling, and stress management. Proper engineering, careful simulation, and diligent maintenance are essential to fully leverage the advantages of complex mould structures. By addressing these factors, manufacturers can produce crates and containers that are both robust and dimensionally stable, meeting the high standards required in modern production environments.

Search...

Search... English

English