Innovative Process for Automotive Lighting System Mould

OEM Custom Automotive lighting system Mould Supplier Supplier Factory

In the automobile manufacturing industry, the manufacturing process of lighting system molds is a crucial part. As a professional Automotive Mold Supplier, we know the importance of mold quality to the performance of automotive lighting systems. This article will take an in-depth look at how we carefully create each lighting system mold to ensure its excellence in the automotive industry.

The design phase of the lighting system mold is the starting point for the entire manufacturing process. Our design team works closely with customers to understand their specific needs and desired effects for their lighting systems. This includes considerations of light pattern, intensity, distribution and coordination with the overall design of the car. After the design is completed, we will use advanced CAD/CAM software to digitally simulate the mold design to ensure the accuracy and feasibility of the design.

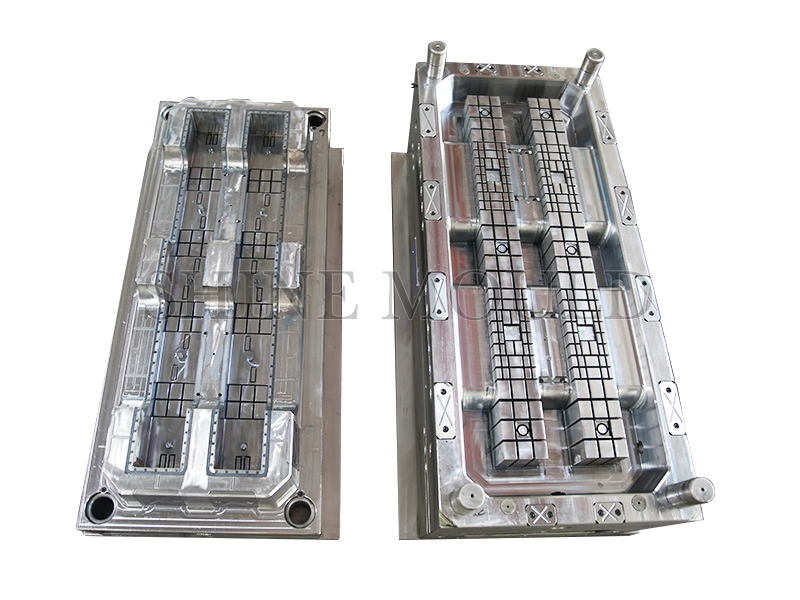

Next, enter the mold manufacturing stage. We use high-precision CNC processing equipment to manufacture the core components of the mold to ensure that every detail meets the design requirements. At this stage, we will pay special attention to the cooling system design of the mold, because good cooling effect is crucial to improve production efficiency and extend mold life. In addition, we also use electric discharge machining (EDM) technology to process the complex shapes and fine parts of the mold to ensure the accuracy and complexity of the mold.

After the mold manufacturing is completed, we will conduct strict quality inspection. This includes precise measurement of mold dimensions, as well as inspection of mold surface finish. We use precision measuring tools, such as coordinate measuring machines, to ensure that every dimension of the mold meets design standards. At the same time, we will also conduct trial mold testing to verify the performance of the mold in actual production.

Material selection is also a key factor in the manufacturing process of lighting system molds. We select high-quality steel and alloy materials, which have good wear resistance, corrosion resistance and thermal stability, which can ensure that the mold maintains stable performance during a long production process. Additionally, we heat treat and surface treat the mold to further improve its durability and anti-stick properties.

After the mold is put into use, as an Automotive Mold Supplier, we will also provide continuous technical support and services. This includes regular maintenance and repair of molds, as well as providing solutions to problems that may arise during production. Our goal is to ensure that customers can use our lighting system molds smoothly and achieve efficient and stable production.

As the automotive industry continues to develop, the design and manufacturing of lighting system molds are also constantly improving. As a professional Automotive Mold Supplier, we keep up with industry trends and continuously develop new technologies and materials to meet the market's demand for lighter, more energy-saving, and smarter lighting systems. For example, we are exploring the use of carbon fiber composites to make molds to reduce their weight and increase their strength.

In short, the manufacturing of lighting system molds is a complex and delicate process, involving many aspects such as design, material selection, processing technology, quality control and follow-up services. As a professional Automotive Mold Supplier, we are committed to providing customers with high-quality lighting system molds through continuous technological innovation and optimization to meet their high standard requirements in automobile manufacturing. We believe that through our efforts, we can promote the development of automotive lighting systems and provide drivers with a safer and more comfortable driving experience.

Search...

Search... English

English

.jpg)