Key Factors to Consider When Selecting a Bucket Mould Manufacturer

When sourcing molds for production, selecting the right Bucket Mould manufacturer is critical to ensuring the quality, efficiency, and cost-effectiveness of your production process. Whether you are manufacturing industrial buckets, storage containers, or custom-designed buckets, the right manufacturer can make a significant difference in the success of your product line. But with so many options out there, how do you choose the right one?

One of the important factors to consider when selecting a Bucket Mould manufacturer is their level of experience and expertise in the industry. A manufacturer with years of experience is more likely to understand the complexities of the molding process and produce high-quality molds. Experienced manufacturers also tend to have a better grasp of industry standards and can offer valuable advice on design optimization and material selection.

Quality is paramount when selecting a Bucket Mould manufacturer. A mold that is poorly made can result in defects in the final product, impacting both functionality and appearance. Ensure that the manufacturer adheres to strict quality control measures throughout the production process. This includes inspecting raw materials, testing mold designs, and conducting regular checks during the production phase.

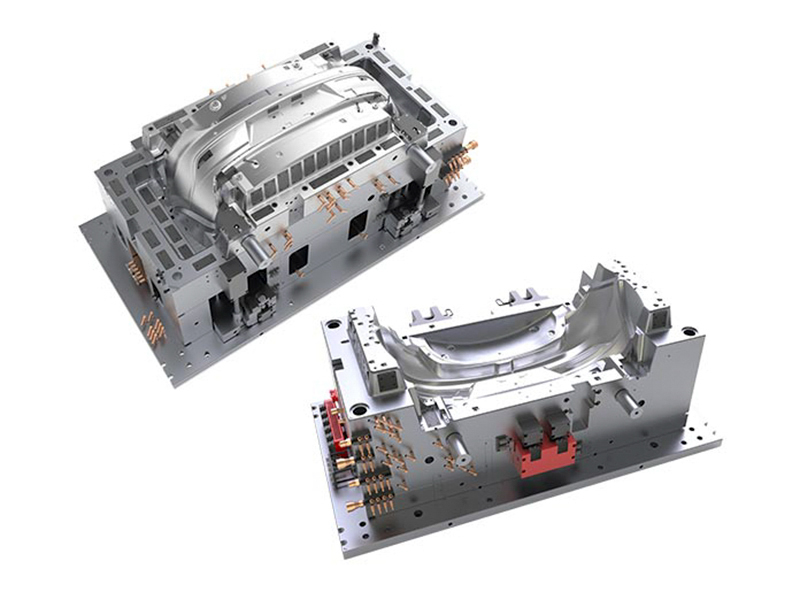

The material used for the mold is also essential for durability. A Bucket Mould is subject to high pressure and heat during the injection molding process, so it’s important to use durable materials such as high-quality steel or aluminum alloys. Ask the manufacturer about their material sourcing and whether they use industry-standard or specialized materials for making molds.

Each customer may have unique requirements when it comes to the design and functionality of their Bucket Mould. Whether you need a specific size, shape, or innovative features for your product, customization options are essential. When choosing a manufacturer, ensure they are capable of designing and producing molds tailored to your specific needs.

delivery times are a crucial factor when selecting a Bucket Mould manufacturer, especially if you are working on a tight production schedule. Delays in mold production can result in production bottlenecks, which can have a ripple effect on the entire supply chain.

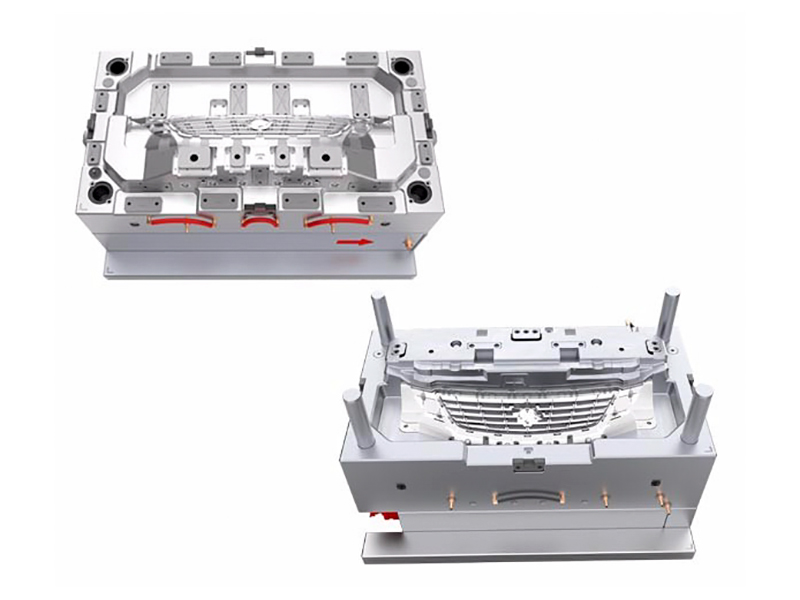

The technology and equipment used by the manufacturer play a major role in the precision and efficiency of the Bucket Mould production process. Modern manufacturing techniques, such as computer-aided design (CAD) and computer-aided manufacturing (CAM), can significantly enhance the accuracy of mold designs and improve the overall quality of the final product.

Check whether the manufacturer uses advanced machinery and software. Manufacturers with advanced technologies will be able to offer precise designs and faster production times, which can result in better-quality molds and fewer defects.

While cost should never be the only deciding factor, it’s essential to choose a Bucket Mould manufacturer that offers competitive pricing without compromising on quality. When evaluating costs, consider the total cost of ownership, which includes not only the mold's price but also shipping, maintenance, and any future modifications that may be necessary.

A mold may need adjustments, repairs, or maintenance after it has been used in production. For this reason, it’s important to choose a Bucket Mould manufacturer that offers reliable after-sales support and maintenance services. Some manufacturers provide ongoing support, including mold inspection, repairs, and modifications, which can extend the mold's life and improve its performance.

Lastly, always check the reputation of the Bucket Mould manufacturer before making a decision. Look for customer reviews, testimonials, and case studies to gain insight into their reliability and service quality. If possible, ask for references from businesses that have worked with the manufacturer in the past.

Selecting the right Bucket Mould manufacturer involves careful consideration of various factors, from experience and expertise to material selection and customization capabilities. By taking the time to evaluate manufacturers based on these criteria, you can ensure that the molds you receive meet your specific requirements, are built to last, and help streamline your production process.

Search...

Search... English

English

-1.jpg)