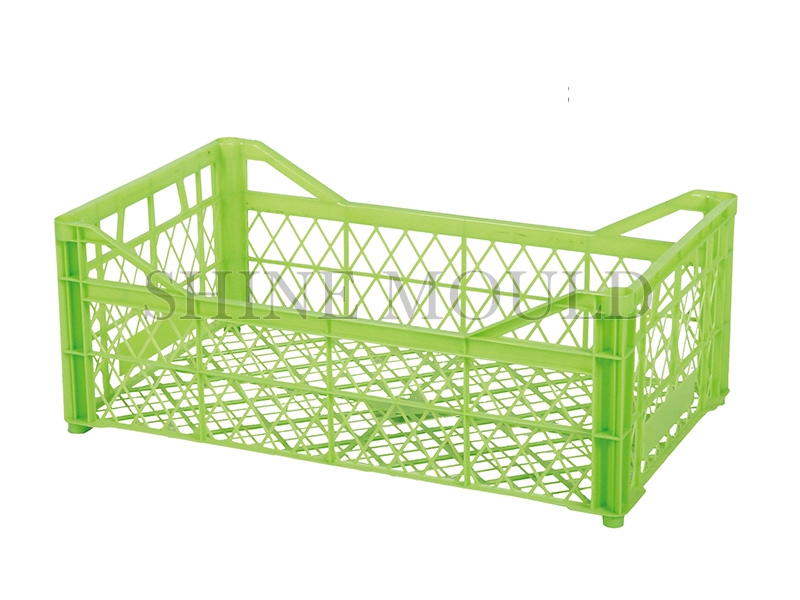

Lightweight and Modular Crate Mould Designs for Efficiency

In modern manufacturing, efficiency and flexibility are critical considerations for high-volume production. Traditional moulds are often heavy and complex, which can limit the speed of setup, handling, and maintenance. In response to these challenges, engineers have explored the concept of lightweight and modular designs. Such innovations aim to reduce mould weight, simplify assembly, and enhance adaptability, thereby improving overall production efficiency. These advancements are particularly relevant in industries that require frequent mould changes or customization for different product specifications.

Benefits of Lightweight Crate Moulds

Reducing the weight of a mould brings multiple advantages. A lighter mould can be more easily handled by machinery or operators, decreasing the time required for installation and removal. This can cause shorter production downtime and increased throughput. Additionally, a reduction in weight can decrease wear and tear on supporting equipment such as presses or robotic arms, prolonging the lifespan of both the mould and the machinery. Lightweight designs may also allow for faster heat transfer during the injection or cooling process, resulting in shorter cycle times and more consistent product quality.

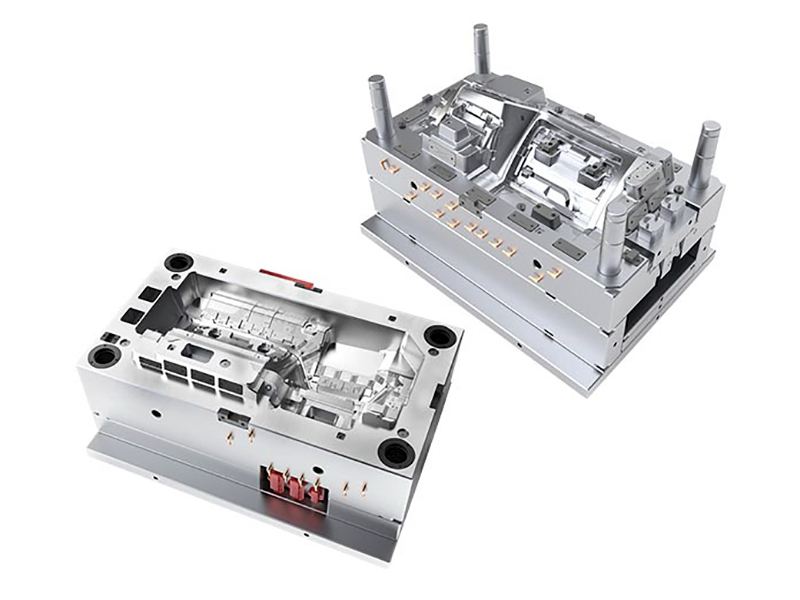

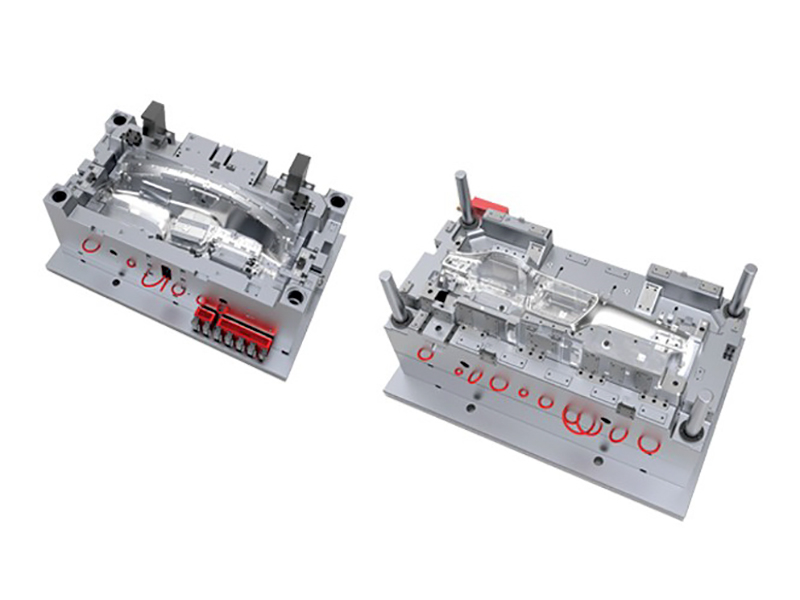

Modular Design Concepts

Modular moulds are constructed from interchangeable components that can be assembled in different configurations depending on production needs. This design philosophy enables manufacturers to adapt to a wide variety of product shapes and sizes without the need for entirely new moulds. Modular Crate Moulds allow sections of the mould to be replaced individually, rather than the entire unit, reducing maintenance costs and downtime. The modular approach also facilitates easier storage and transportation, as individual components are more compact and manageable than a single large mould.

Impact on Production Flexibility

The combination of lightweight and modular design significantly enhances production flexibility. Manufacturers can quickly switch between different product variants by reconfiguring modules or adjusting inserts, without extensive retraining or machinery recalibration. This flexibility is particularly valuable in industries with high demand for customized crates or limited production runs. Moreover, modular designs support incremental improvements; individual modules can be optimized for wear resistance or surface finish without replacing the entire mould, improving overall operational efficiency over time.

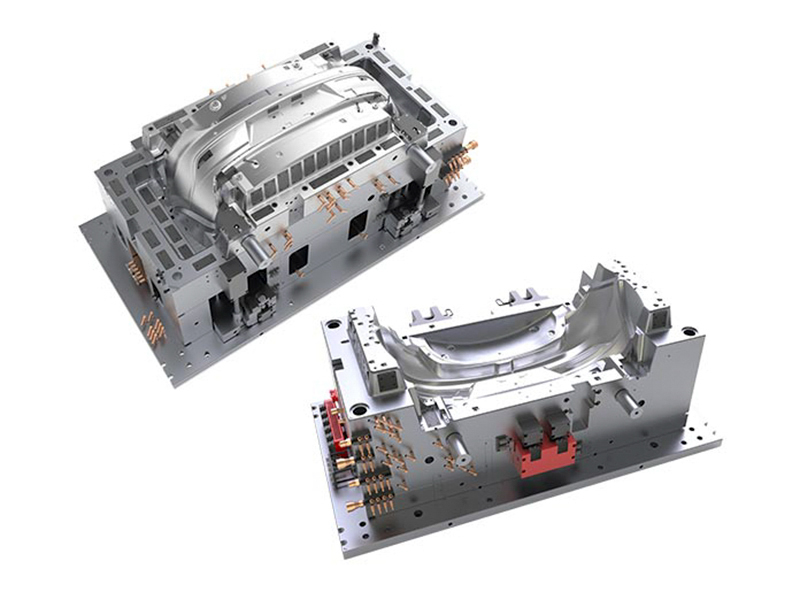

Challenges and Considerations

Despite the benefits, implementing lightweight and modular Crate Moulds requires careful engineering. Material selection is critical to ensure that reducing weight does not compromise structural integrity or dimensional accuracy. Joining mechanisms between modules must be precise and durable to prevent misalignment or leakage during the moulding process. Additionally, thermal management must be addressed, as lighter sections may have different heat retention and cooling characteristics, potentially affecting cycle times and product quality. Engineers must balance these considerations to fully realize the advantages of innovative mould designs.

Lightweight and modular design represents a promising direction for improving the efficiency and flexibility of mould-based manufacturing. By reducing weight and enabling interchangeable modules, Crate Moulds can be handled more easily, reconfigured rapidly, and maintained more efficiently. While technical challenges exist, careful design and material selection can mitigate potential issues, making these moulds an effective solution for modern production demands. Adoption of such innovative approaches not only increases throughput but also enhances adaptability in an evolving manufacturing environment.

Search...

Search... English

English

.jpg)