Manufacturing Of Crate Mould And Dustbin Mould

Manufacturing of Crate Mould and Dustbin Mould

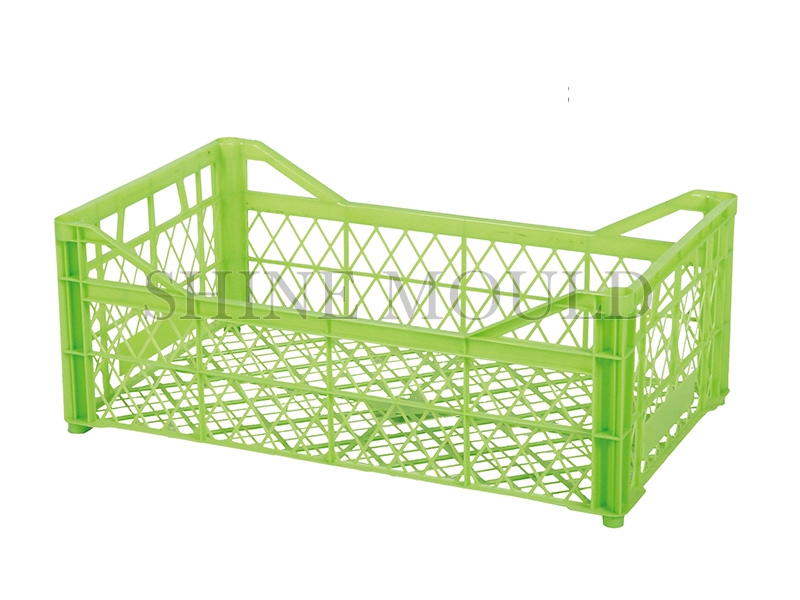

Industrial plastic products cover a wide range, including Crate Mould, pallet molds, auto parts, electrical application parts molds, PVC pipe fittings molds, etc. These industrial products are produced using rigid plastic materials including high-density polyethylene (HDPE), low-density polyethylene (LDPE), polyvinyl chloride (PVC), and acrylonitrile butadiene styrene (ABS).

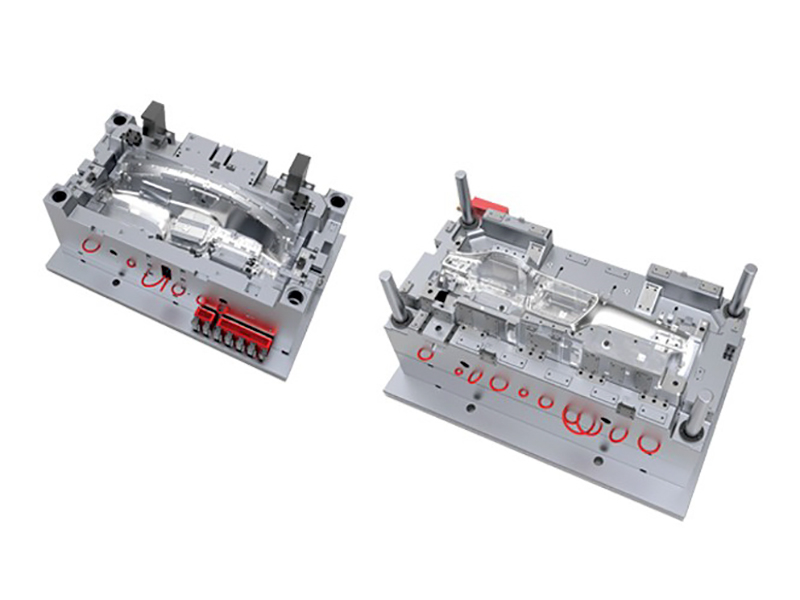

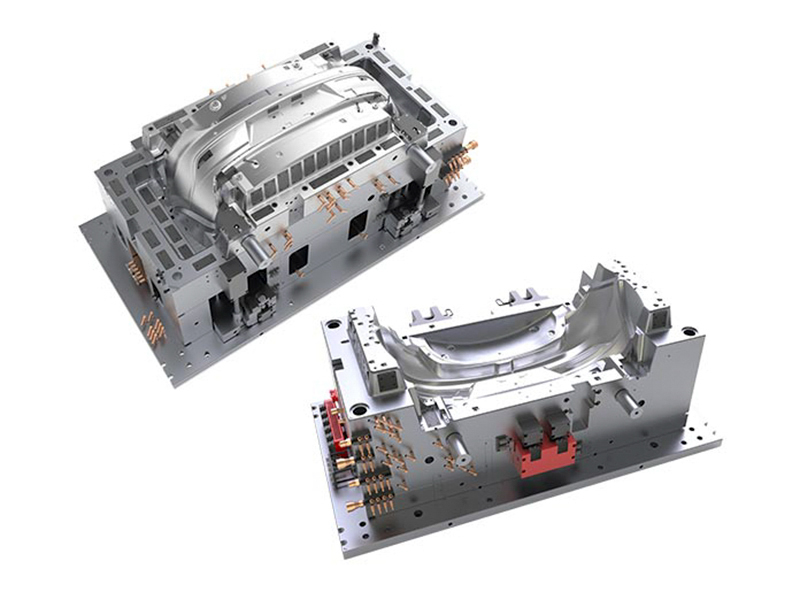

Before choosing the right steel for these molds, the most basic points to pay attention to are to understand the complexity of the parts, the flow of materials, conduct structural analysis and provide a suitable ejection system for the product. In many cases, it is important to conduct mold flow analysis before mold design and mold assembly, and functional design.

Every industrial product mold needs to reach the exact part size and part weight. Therefore, it is important to consider the shrinkage of the material after molding. For this reason, the quality of the gate system, cooling line, and hot runner plays an important role in obtaining high-quality final products.

Mold cooling time in crates, pallets, electronic parts, and pipe fitting molds is the biggest factor to consider for high-end products. Many tool manufacturers use conventional cooling designs for these products but need to design customized cooling systems for each part. The optimization of the cooling process can save thousands of dollars during the entire production cycle. In many industrial categories, especially in the case of multi-cavity complex molds, even cooling lines are regarded as the backbone of product functions.

In the next stage, the choice of steel determines the life of the mold. The most commonly used steels in HDPE crates and pallets are China P20 for cores and cavities, and C45 for mold bases. The hardness of steel is 35×38 HRC. Using China P20 can run at least 500,000 without failure.

Parts made of PVC require steel such as 3Cr13 (a type of stainless steel) from China, which helps to make the material flow well without sticking, especially in the case of hollow products (such as pipe fittings). This mold steel does not require chrome plating or polishing and is hard enough to produce more than 500,000 shots.

Search...

Search... English

English