Optimizing Gate and Runner Design of Crate Mould to Reduce Defects

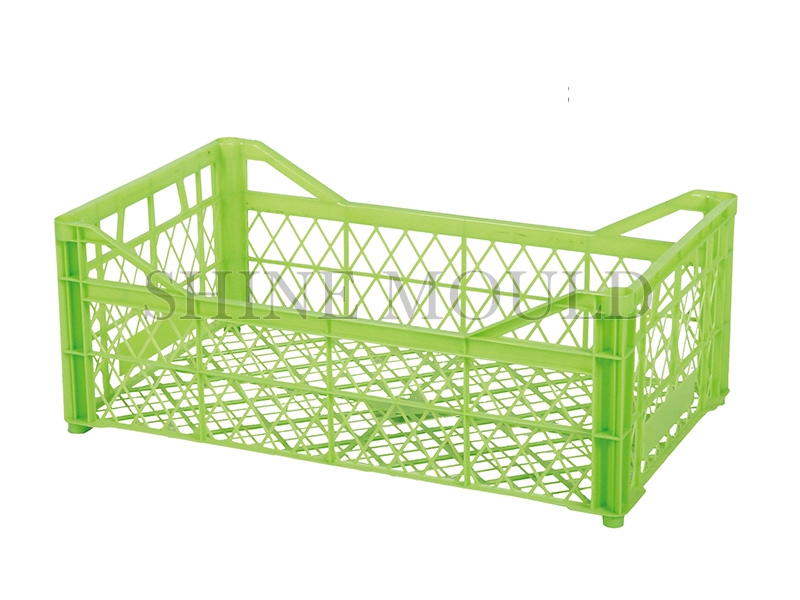

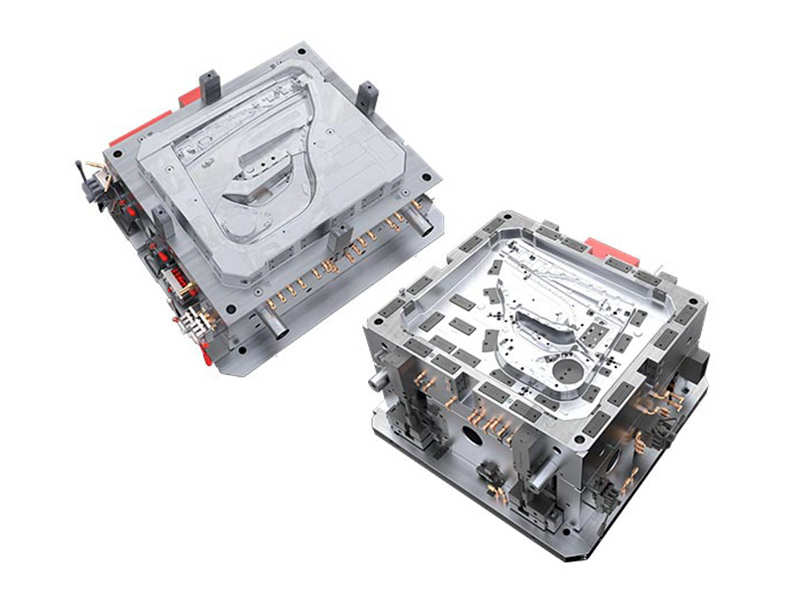

The design of gates and runners is critical to the quality of the final product. Crate Mould, used for producing plastic crates and similar containers, relies on efficient material flow to prevent defects such as sink marks, warping, or incomplete filling. The gate serves as the entry point for molten plastic into the cavity, while the runner system distributes material to multiple areas of the mould. Poorly designed gates or runners can cause uneven flow, resulting in weak spots or cosmetic imperfections. Therefore, optimizing this aspect of the mould is essential for high-quality production.

Factors Influencing Flow Efficiency

Several factors affect the efficiency of flow through the gates and runners. The size and shape of the gate influence both the flow rate and pressure drop of the molten plastic. A gate that is too small may create excessive backpressure, causing incomplete filling, while a gate that is too large can cause flash or uneven surface finish. Similarly, the runner layout must ensure uniform distribution to all cavities in multi-cavity moulds. Sharp turns, sudden diameter changes, or long runner paths can cause turbulence, temperature loss, or premature solidification of the plastic. Considering these factors during design improves flow stability and reduces the likelihood of defects.

Gate Type Selection

The choice of gate type is another key aspect of optimisation. Pin gates, edge gates, and fan gates each have specific applications and influence the performance of Crate Mould differently. Pin gates are suitable for small injection points, providing a gate vestige but may require careful pressure control. Edge gates allow for better flow in larger sections, reducing internal stress and ensuring uniform packing. Fan gates help distribute molten material evenly across wide areas of the cavity. Selecting the appropriate gate type based on crate geometry, wall thickness, and production requirements can significantly reduce common injection moulding defects.

Runner System Optimization

Runner systems should be designed to balance flow rates across all cavities, especially in multi-cavity moulds. Hot runner systems offer advantages by keeping the plastic molten until it reaches the cavity, reducing waste and cycle time. Cold runner systems are simpler but require precise diameter and path optimization to prevent pressure loss and uneven filling. Proper insulation, consistent cross-sectional areas, and bends help maintain uniform temperature and flow velocity. Computational flow simulation tools are often employed to model plastic behavior within the runner system, allowing engineers to identify potential issues before mould fabrication.

Practical Testing and Adjustments

Even with careful design, real-world testing is essential to fine-tune gates and runners. Trial runs can reveal unexpected flow imbalances, air traps, or weld lines. Adjustments may include modifying gate location, changing runner diameters, or improving venting to eliminate trapped air. Continuous monitoring of part quality and cycle parameters ensures that the Crate Mould produces consistent, defect-free components throughout production. Feedback from testing allows for iterative improvements, causing a more reliable manufacturing process.

Optimizing the gate and runner design of Crate Mould is fundamental to reducing defects and ensuring high-quality plastic crate production. Careful consideration of gate size, type, and location, along with efficient runner layout, ensures uniform material flow and reduces common injection moulding problems. By combining thoughtful design with practical testing and adjustments, manufacturers can achieve consistent part quality, lower waste, and improved production efficiency. Properly optimized gates and runners are therefore a cornerstone of reliable and cost-effective crate moulding operations.

Search...

Search... English

English