Overcoming Micro Part Injection Challenges in Toy Moulds

Introduction to Small-Part Challenges in Toy Manufacturing

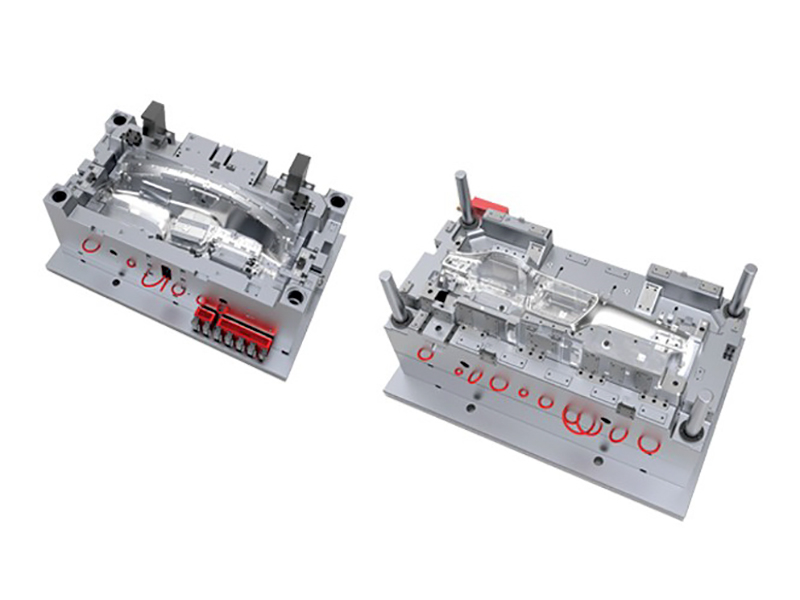

A Children Toy mould is often required to produce components with extremely small dimensions, fine details, and tight tolerances. These parts may include miniature gears, connectors, decorative features, or safety-related elements that must fit together precisely. Injection molding of such small components presents unique challenges, including incomplete filling, flashing, deformation, and difficulty in ejection. Addressing these issues requires careful mould design, material selection, and process control to ensure both product quality and production efficiency while meeting strict safety standards for children’s products.

Precision Cavity and Core Design

One of the important strategies for handling small parts is the precise design of the cavity and core. Micro-scale features demand high-accuracy machining to ensure dimensional consistency. Even minor deviations can cause assembly problems or functional failure. Polished cavity surfaces reduce flow resistance and improve material filling, while appropriate draft angles help with smooth demolding. In addition, maintaining uniform wall thickness in small components reduces the risk of sink marks and internal stress, which are common problems in miniature injection-molded parts.

Optimized Runner and Gate Systems

The runner and gate system plays a critical role in ensuring that molten plastic reaches every tiny feature of the mould. For small toy components, gate size and position must be carefully optimized to balance flow speed and pressure. Gates that are too small may restrict material flow, causing short shots, while oversized gates can cause excessive shear or surface defects. Well-designed runners help maintain stable melt flow and temperature, allowing the plastic to fill micro details consistently without degrading material properties.

Advanced Venting Techniques

Air entrapment is a frequent issue in the injection molding of small parts. When air cannot escape efficiently from fine cavities, it can result in burn marks, incomplete filling, or surface blemishes. Effective venting solutions are essential for micro-featured toy moulds. Micro-vents and precisely placed air channels allow trapped gases to escape during injection without causing flash. Proper ventilation improves filling performance and enhances surface quality, especially in intricate toy components with complex geometries.

Material Selection and Flow Behavior

Choosing the right plastic material is another key factor in overcoming small-part molding challenges. Materials with good flowability and stable shrinkage characteristics are better suited for fine details. The melt flow index of the plastic directly affects its ability to fill narrow cavities and thin walls. In toy manufacturing, materials must also comply with safety regulations, making it essential to balance processing performance with non-toxicity and durability. Proper material selection helps reduce defects while ensuring the final product is safe for children.

Temperature and Process Control

Precise control of temperature and injection parameters is critical when molding small toy parts. Higher mould temperatures can improve flow into micro features, while controlled injection speed and pressure help prevent material degradation or excessive shear. Cooling must also be carefully managed to avoid warping or uneven shrinkage. A stable and well-monitored process window ensures repeatability, which is especially important for high-volume toy production where consistency is essential.

Ejection System for Delicate Components

Ejecting small and delicate toy parts without damage is another major challenge. Traditional ejector pins may leave marks or deform thin features if not properly designed. Customized ejection systems that distribute force evenly help release parts smoothly. Proper alignment and timing of ejection prevent sticking or breakage, maintaining the integrity of fine details and ensuring efficient cycle times.

Search...

Search... English

English

.jpg)