Package Mould Compatibility with Various Molding Processes

Versatility in Modern Packaging Production

In contemporary packaging manufacturing, the flexibility and adaptability of moulds are critical to meeting diverse product requirements. Package moulds must perform efficiently across different production methods, including injection molding, compression molding, and thermoforming. Understanding the suitability of a specific mould for each process is essential for ensuring product quality, minimizing defects, and optimizing production efficiency. By evaluating the compatibility of a mould with various manufacturing techniques, manufacturers can improve operational flexibility and reduce costs.

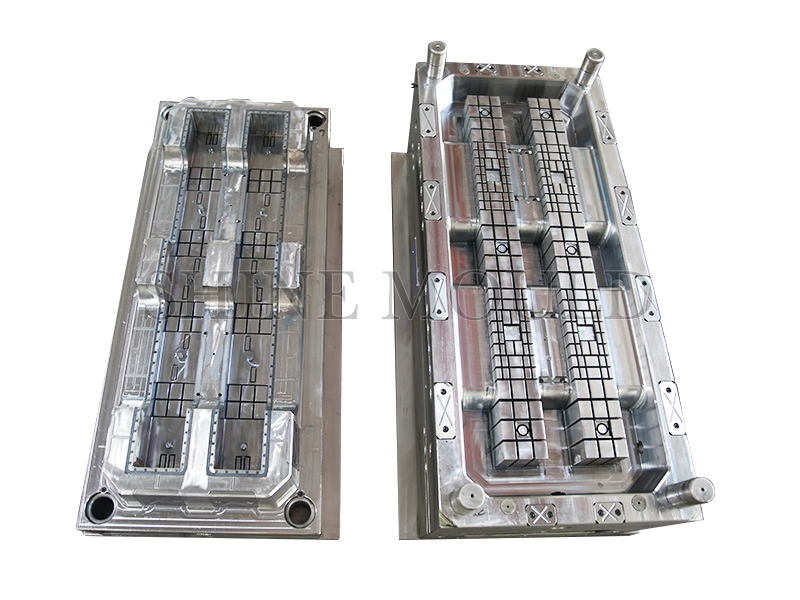

Injection Molding Compatibility

Injection molding is widely used for producing high-precision, complex packaging components. The suitability of a Package Mould for this process depends on its ability to withstand high injection pressures, provide precise cavity filling, and maintain dimensional accuracy. Molds designed for injection molding typically feature reinforced cavities, optimized cooling channels, and smooth surface finishes to facilitate rapid material flow and uniform curing. Proper venting is also crucial to prevent air traps and voids. When a mould is appropriately engineered for injection molding, it can consistently produce detailed, high-quality packaging items at high production rates.

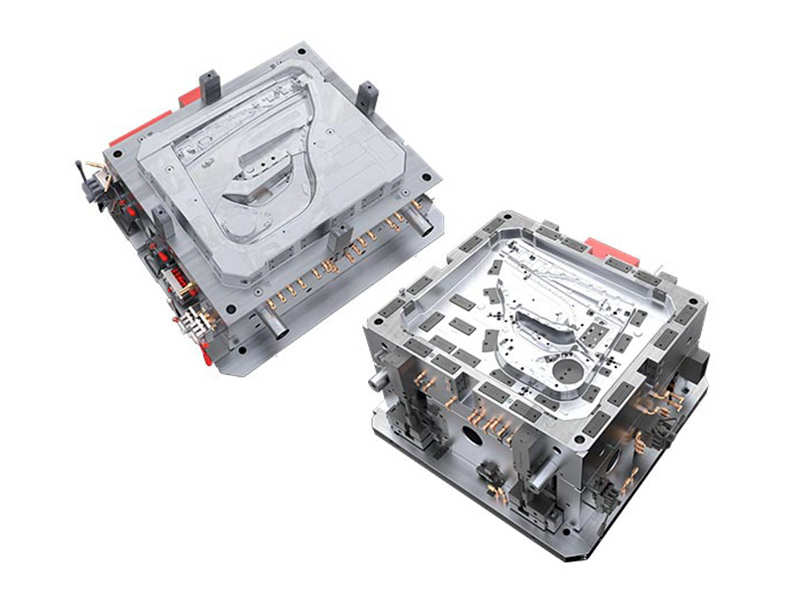

Compression Molding Adaptability

Compression molding is commonly employed for thermosetting plastics and elastomers, which require heat and pressure to form into the desired shape. The Package Mould used in this process must endure elevated temperatures and significant mechanical forces without deformation. Mould design considerations include sufficient wall thickness, robust structural support, and precise alignment features to ensure even material distribution and consistent part quality. While compression molding is generally slower than injection molding, using molds tailored for this process allows for efficient production of large, durable packaging components with defects.

Thermoforming and Other Specialized Processes

Thermoforming involves heating plastic sheets until they become pliable and then forming them over a mould. The suitability of a Package Mould for thermoforming depends on its ability to provide uniform contact, allow controlled cooling, and resist wear from repeated sheet contact. Surface finish and mould geometry play critical roles in achieving consistent wall thickness, smooth surfaces, and accurate product dimensions. Moulds compatible with specialized processes, such as vacuum forming or pressure-assisted forming, expand the range of packaging designs that manufacturers can produce without additional tooling investments.

Material Considerations Across Processes

The material of the Package Mould influences its adaptability to different processes. High-quality tool steels, alloys, and treated surfaces enhance durability, heat resistance, and dimensional stability. The choice of material must align with the intended manufacturing method to prevent premature wear, thermal deformation, or surface damage. By selecting appropriate materials and incorporating surface treatments, manufacturers ensure the mould maintains its performance across multiple production techniques.

Benefits of Multi-Process Compatibility

A mould compatible with various manufacturing processes provides significant advantages. It reduces the need for multiple dedicated moulds, minimizes changeover time, and lowers tooling costs. Manufacturers can respond more quickly to market demands, accommodate small-batch or custom packaging orders, and maintain high product quality across diverse production methods. Multi-process compatibility also enhances operational flexibility, allowing a single mould to serve multiple production lines and product designs.

Improving Production Efficiency with Versatile Moulds

Evaluating the suitability of a Package Mould across injection molding, compression molding, and thermoforming processes is essential for optimizing production efficiency and ensuring consistent product quality. Proper design, material selection, and process-specific features allow moulds to perform reliably under different manufacturing conditions. By leveraging versatile moulds, manufacturers can achieve flexibility, reduce costs, and maintain high standards for packaging products across a variety of production methods.

Search...

Search... English

English

.jpg)