Practicality Meets Innovation: The Versatility of Plastic Injection Moulds in Furniture Production

Sales Plastic Injection Mould, Custom Plastic Furniture Mould, Plastic Furniture Mould Manufacturer

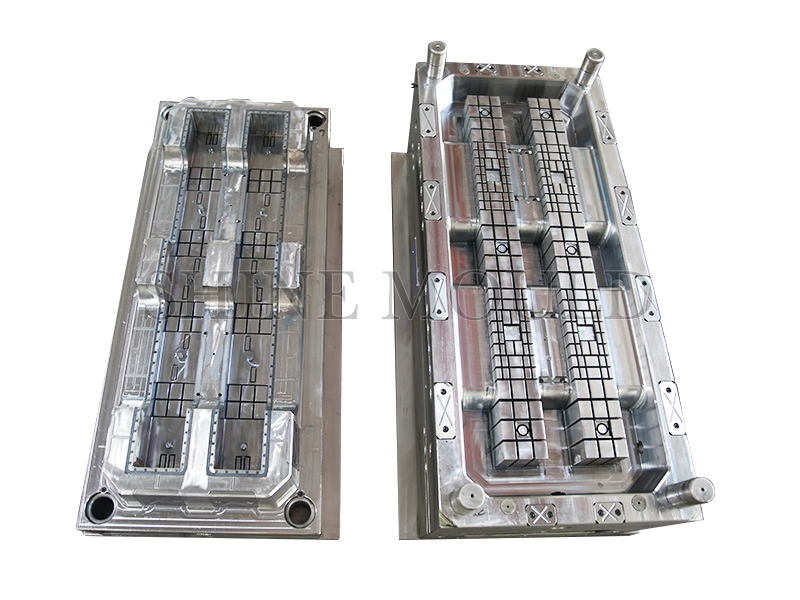

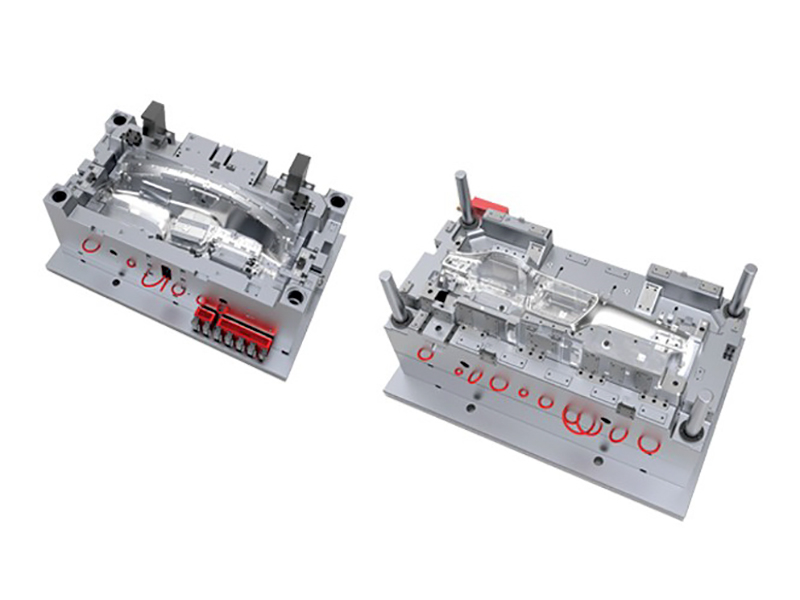

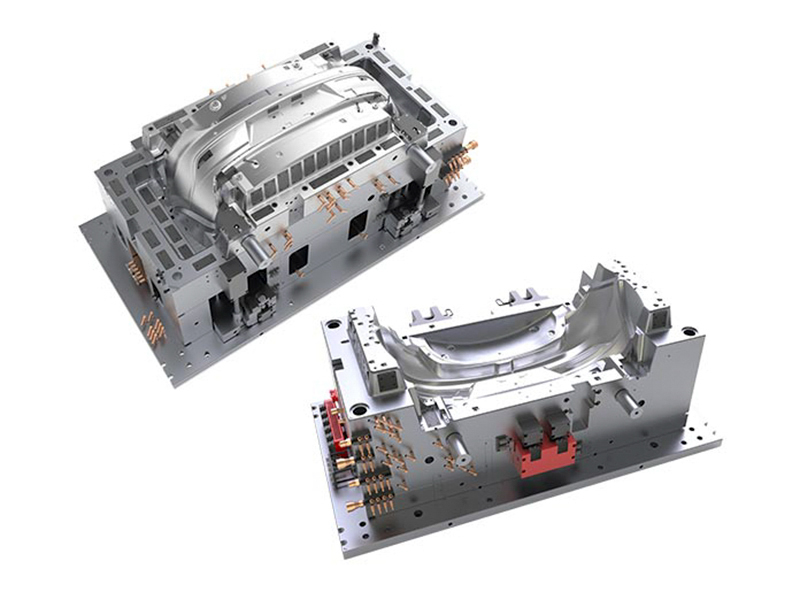

In the realm of furniture production, one crucial element that plays a pivotal role in shaping the final outcome is the plastic injection mould. This ingenious tool showcases its remarkable functionality and versatility, making it an indispensable part of the furniture manufacturing process. Let's explore the various applications and benefits of plastic injection moulds in the creation of high-quality plastic furniture.

1. Precise and Consistent Formability:

Plastic injection moulds excel in delivering precise and consistent forms for plastic furniture pieces. The mould's intricate design and construction ensure that every detail and contour of the furniture piece is accurately reproduced. This precision allows manufacturers to create furniture with a seamless finish, boosting both its visual appeal and functionality.

2. Wide Range of Furniture Designs:

Plastic injection moulds cater to the diverse needs of furniture designers by offering an extensive array of design possibilities. Whether it's modern, minimalistic chairs or elegant and ergonomic tables, these moulds can effortlessly adapt to various styles and specifications. The adaptability of plastic injection moulds expands the creative horizons of furniture manufacturers, enabling them to produce a range of innovative designs.

3. Enhanced Durability and Longevity:

Plastic furniture moulds are specifically engineered to withstand heavy usage and environmental challenges. By utilizing robust materials and advanced manufacturing techniques, these moulds ensure that the produced furniture pieces maintain their structural integrity for extended periods. The durability of the moulds translates into long-lasting, reliable furniture solutions that are built to endure.

4. Reduced Production Time and Cost:

The efficiency of plastic injection moulds contributes significantly to reducing production time and cost. The moulds efficiently shape the molten plastic into the desired furniture design in a fraction of the time it would take using traditional manufacturing methods. Additionally, the high repeatability of plastic injection moulds minimizes material waste and the need for excessive post-production modifications, resulting in significant cost savings.

5. Versatile Material Compatibility:

Plastic injection moulds are compatible with a wide range of plastic materials, offering manufacturers flexibility in material selection. From polypropylene to polyethylene, designers can choose materials that best suit the desired furniture properties, such as flexibility, strength, or heat resistance. This versatility expands the possibilities of creating furniture suitable for both indoor and outdoor use, ensuring durability and functionality in various settings.

6. Efficient Mass Production:

Plastic injection moulds excel in mass production scenarios, making them an ideal choice for furniture manufacturers aiming to meet high-volume demands. These moulds facilitate the rapid production of identical furniture pieces with minimal variation, ensuring consistency throughout the process. This efficiency enables manufacturers to fulfill orders promptly, reinforcing customer satisfaction and business growth.

7. Eco-Friendly Manufacturing:

Plastic injection moulds promote eco-friendly practices in furniture production. By utilizing precise moulding techniques, manufacturers can minimize material waste and optimize resource utilization. Additionally, the longevity of plastic furniture created with these moulds reduces the need for frequent replacements, significantly reducing environmental impact.

In conclusion, the practicality and versatility of plastic injection moulds in furniture production are undeniable. From precise formability and a broad range of design possibilities to enhanced durability and cost-effective mass production, these moulds provide numerous advantages to furniture manufacturers. With Plastic Injection MouldPlastic Furniture Mould at the forefront of furniture production, the industry can forge ahead with innovation and continue to meet the evolving demands of both designers and consumers alike.

Search...

Search... English

English

-1.jpg)