Precision Engineering in Automotive Mould Manufacturing

Automotive mould manufacturing stands as a cornerstone in the automotive industry, where precision engineering plays a pivotal role in the production of high-quality components and parts.

1. Historical Foundations:

The roots of automotive mould manufacturing can be traced back to the early days of automobile production. As the automotive industry burgeoned, the need for efficient and standardized manufacturing processes became apparent. Early moulds were basic, serving the purpose of mass-producing components, and laid the foundation for the sophisticated moulds used today.

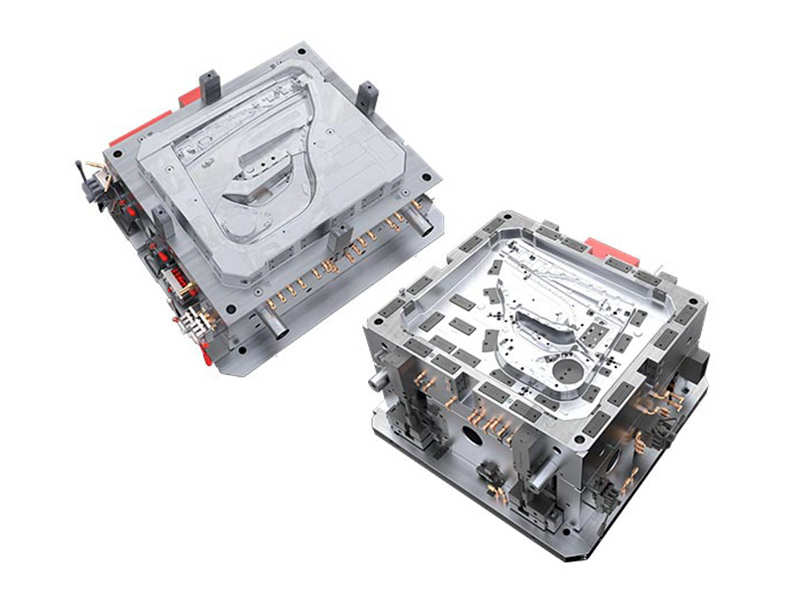

2. Precision Engineering and CAD/CAM Technologies:

Modern automotive moulds are a testament to precision engineering, leveraging cutting-edge technologies such as computer-aided design (CAD) and computer-aided manufacturing (CAM). These technologies enable engineers to design intricate and precisely detailed moulds with exceptional accuracy, ensuring the consistent production of automotive components to exact specifications.

3. Materials and Durability:

The choice of materials in automotive mould manufacturing is critical for ensuring durability and longevity. High-quality metals, such as tool steel or aluminum, are commonly employed to create robust moulds capable of withstanding the demands of high-volume production. The durability of automotive moulds directly influences the quality and performance of the automotive components they produce.

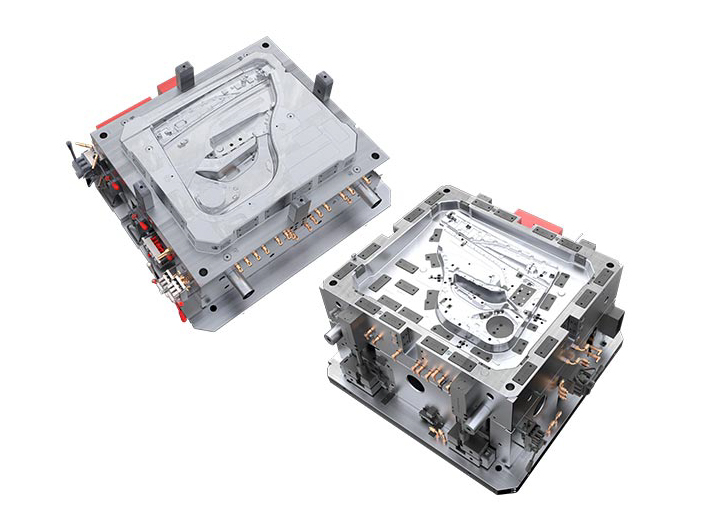

4. Injection Moulding Techniques:

Automotive moulds primarily play a crucial role in the injection moulding process, a highly efficient method for producing complex automotive parts. This process involves injecting molten material, often plastic or metal, into the mould cavity. The intricacies of the mould design dictate the final form and features of the automotive component, making precision and attention to detail paramount in the manufacturing process.

5. Design Innovation for Automotive Excellence:

The evolution of automotive mould manufacturing has seen a shift towards design innovation focused on automotive excellence. Modern automotive designs prioritize efficiency, aerodynamics, and safety. Automotive moulds are crafted to capture these design nuances, ensuring that the final components not only meet functional requirements but also contribute to the overall performance and aesthetics of the vehicle.

6. Customization and Design Flexibility:

Advancements in automotive mould manufacturing have expanded possibilities for customization and design flexibility. Manufacturers can now create moulds that accommodate a diverse range of automotive designs, allowing for unique shapes, textures, and finishes. This flexibility enables the production of automotive components that cater to various styles and design preferences in the market.

7. Efficiency in Production:

Automotive moulds significantly contribute to the efficiency of automotive component production processes. The ability to produce a large number of components efficiently is crucial for meeting the demands of the automotive industry. Well-designed automotive moulds, combined with advanced manufacturing techniques, enhance production efficiency, reduce lead times, and ensure the timely delivery of components to automotive assembly lines.

8. Sustainability Considerations:

In response to the growing emphasis on sustainability, automotive mould manufacturing is incorporating eco-friendly practices. This includes the use of recyclable materials, optimizing production processes to minimize waste, and designing moulds that contribute to the recyclability of the final automotive components. Sustainability in automotive mould manufacturing reflects an industry-wide commitment to responsible and environmentally conscious practices.

9. Impact on the Automotive Industry:

The impact of automotive mould manufacturing on the automotive industry is profound. Reliable and high-quality components are essential for the performance, safety, and overall durability of vehicles. The precision, efficiency, and design possibilities offered by advanced automotive moulds have played a crucial role in shaping the modern automotive landscape, contributing to the development of vehicles that meet and exceed consumer expectations.

Search...

Search... English

English

.jpg)