Relevant Skills To Confirm The Quality Of Bucket Mould

When you find a manufacturer of plastic injection molds for plastic barrel molds, you will have questions. We know that injection molds are the basic tools for making high-quality products. Therefore, as our decades of experience in manufacturing barrel molds, we have provided relevant techniques for confirming the quality of barrel molds. For ease of understanding, take a plastic Bucket Mould as an example.

- Product design

Why list product designs? Before the mold was made, it seemed to be independent. But it plays a key role in manufacturing injection molds. If you or the supplier do not pay attention to it, the trouble will continue to bother you until the mold stops working. For 20L plastic barrels, the basic functions and any special requirements should be checked, and then the barrel design should be carried out and checked through continuous improvement of mold flow analysis to ensure the best injection molding process.

- Mold design

When the product design is good, the experience of mold design will make it an important part of excellent mold design. It is not only related to the bucket forming structure but also related to the worker's productivity, mold life, and maintenance convenience.

These two steps can be regarded as a very important process for manufacturing high-quality plastic bucket molds. Therefore, when you want to check the quality of the mold, discuss these issues with the supplier, and then you will see how to do it.

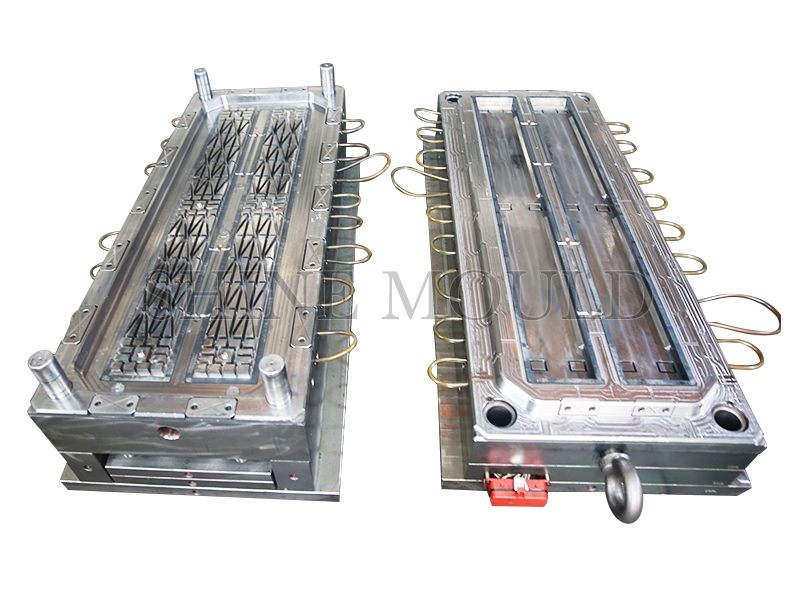

- Mould

If you do well in the first and second steps, if the mold equipment is accurate and the workers are responsible, mold processing will be very easy. Quality control is one of the key processes. If the supplier has a complete quality control system to control the accuracy of mold parts, it will be very good.

- Mold testing

Even if the above steps are well controlled, the mold test is still necessary. In any case, the practice is perfect. Check the method of mold testing, because most people cannot reach the supplier every time, so please confirm the method first. Usually, the most basic thing is to test whether the mold meets your requirements through molded products, but this is far from enough.

The best test is to simulate production, make it run in your factory, and then check whether all mold movements and products are good enough. As for the time, the situation will be different. For a 20L plastic barrel mold, the simulated production can usually be maintained for 24 hours.

- Mold operation

This is the last but not the least important point because it can check the previous steps well, and time can tell you the truth, which can help you and your suppliers become better.

In summary, you can see that a good plastic paint bucket mold mainly depends on the degree of professionalism of the supplier. Hope it can help you understand the basic skills of confirming plastic bucket molds.

Search...

Search... English

English

-1.jpg)