Stable Slide and Core Design for Drawer Moulds

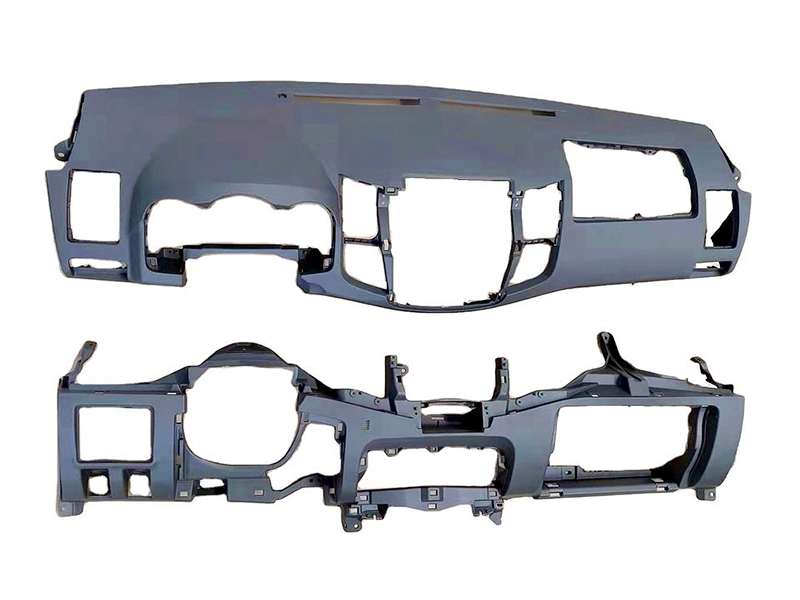

In plastic injection molding, drawers often feature complex geometries such as undercuts, internal ribs, guide rails, and locking features. These characteristics make the slide and core mechanisms essential parts of mould design. A stable slide and core structure directly affects product accuracy, surface quality, cycle time, and mould lifespan. When these mechanisms are poorly designed, problems such as misalignment, excessive wear, flashing, or even mould damage can occur. Therefore, understanding how to design stable slide and core systems is critical for achieving reliable and efficient production with a Drawer Mould.

Understanding the Role of Slides and Core Pulling Systems

Slides and core pulling mechanisms are used to form undercuts or side features that cannot be released by simple vertical mould opening. Slides typically move horizontally or at an angle, while core pulling systems may operate mechanically, hydraulically, or via inclined pins. Stability in these systems ensures that movement is smooth, positioning is accurate, and repeated cycles do not cause deviation. A well-designed Drawer Mould relies on precise interaction between these moving components to maintain consistent product dimensions over long production runs.

Structural Design for Mechanical Stability

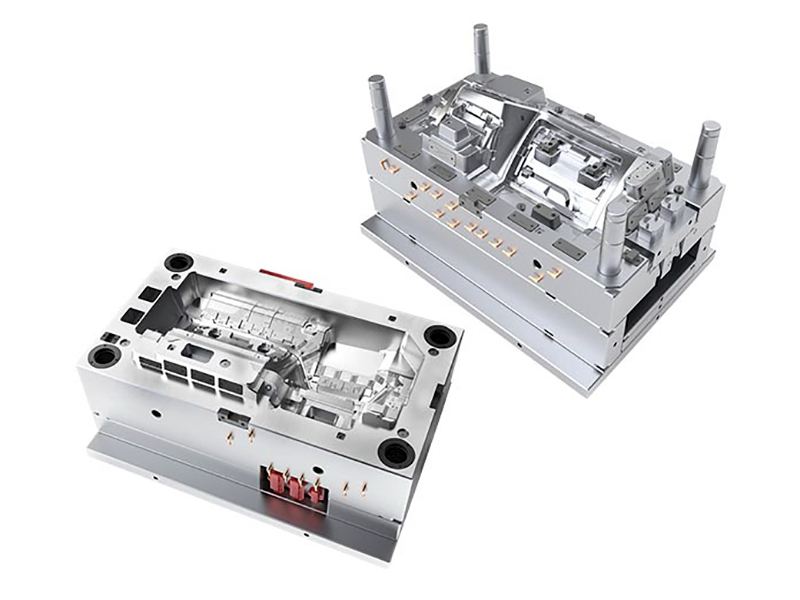

The foundation of a stable slide and core structure lies in solid mechanical design. Slides should have sufficient thickness and support length to resist deformation under injection pressure. Guide rails and wear plates must be designed to distribute forces evenly, preventing localized stress concentration. Proper alignment between the slide, cavity, and core is essential to avoid friction and jamming. Designers often increase contact surfaces and use reinforced backing plates to improve rigidity, especially for large or deep drawer components.

Material Selection and Surface Treatment

Material choice plays a crucial role in stability and durability. High-strength mould steels with good toughness are commonly used for slides and cores to withstand repeated movement and pressure. Surface treatments such as nitriding, hard chrome plating, or PVD coatings reduce friction and wear, improving long-term stability. These treatments also help maintain dimensional accuracy by reducing abrasion between moving parts. In high-volume production, enhanced surface hardness can significantly extend service life and reduce maintenance frequency.

Guidance and Locking Mechanisms

Stable movement depends heavily on effective guidance and locking systems. Precision guide rails ensure that slides move in a controlled and predictable path. Locking mechanisms, such as angled locks or wedge blocks, hold slides firmly in position during injection, preventing backward movement caused by melt pressure. Reliable locking is especially important for Drawer Mould applications where side walls and internal structures must meet strict dimensional tolerances. Properly designed locks improve both safety and consistency.

Synchronization and Motion Control

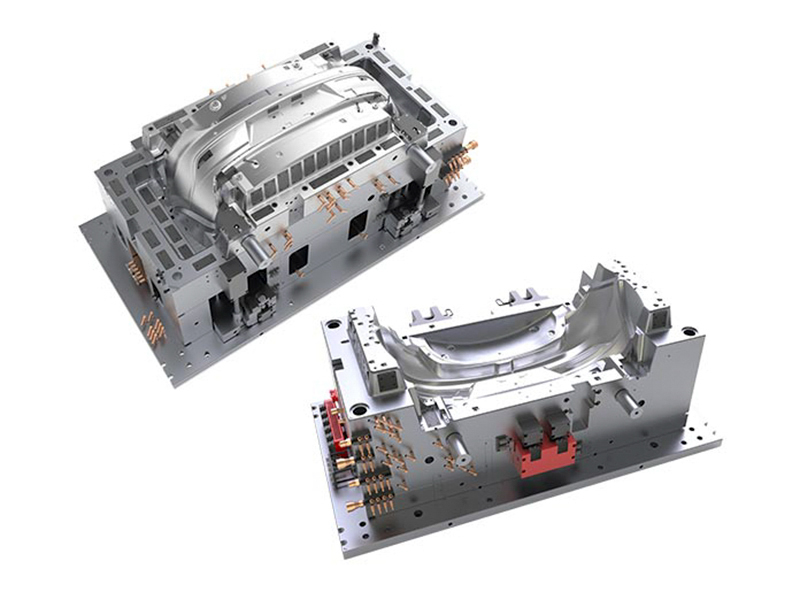

Slides and core pulls must operate in precise coordination with the mould opening and closing sequence. Mechanical timing mechanisms, such as inclined guide pins, ensure that slides retract before ejection begins. Hydraulic or pneumatic systems offer more control and are often used in complex designs, though they require careful tuning to maintain stability. Smooth acceleration and deceleration of moving parts reduce impact forces, reducing wear and improving operational reliability.

Cooling and Thermal Stability

Temperature variation can affect slide and core stability by causing uneven expansion. Integrating proper cooling channels near slides and cores helps maintain uniform temperature distribution. Thermal stability ensures consistent movement clearances and prevents sticking or misalignment during continuous production. Effective cooling design is particularly important in thick or large drawer components where heat buildup can be significant.

Stable slide and core design is a key factor in the successful production of plastic drawers. Through robust structural design, appropriate material selection, reliable guidance and locking systems, controlled motion, and effective cooling, manufacturers can significantly enhance mould stability. When these elements are carefully integrated, a Drawer Mould delivers accurate parts, longer service life, and efficient, trouble-free production in demanding manufacturing environments.

Search...

Search... English

English

-1.jpg)