Technical Strategies for Adapting Molds to Multi-Component and Multi-Color Injection Processes

Introduction to Multi-Color Injection Molding in the Toy Industry

The modern toy industry demands visually engaging, functionally complex, and durable products that meet both safety standards and market trends. Multi-color and dual-shot injection molding have become essential manufacturing technologies, enabling the integration of multiple colors or materials into a single toy part without additional assembly. This has driven the evolution of mold design and function. Particularly, a well-designed Children Toy Mould must be able to accommodate these advanced techniques through precise engineering, material compatibility, and automated coordination.

Key Principles of Multi-Color and Dual-Shot Molding

Multi-color injection molding generally refers to the process where two or more different colored plastics are injected sequentially or simultaneously into the mold. Dual-shot (or two-shot) molding, a subset of this process, involves injecting two different materials or colors in a controlled sequence, forming a strong bond between layers. This process is ideal for creating soft-touch features, contrasting visual details, or functional integrations such as seals and buttons. Both techniques enhance design freedom while reducing post-processing time.

Mold Design Adjustments for Color Segmentation

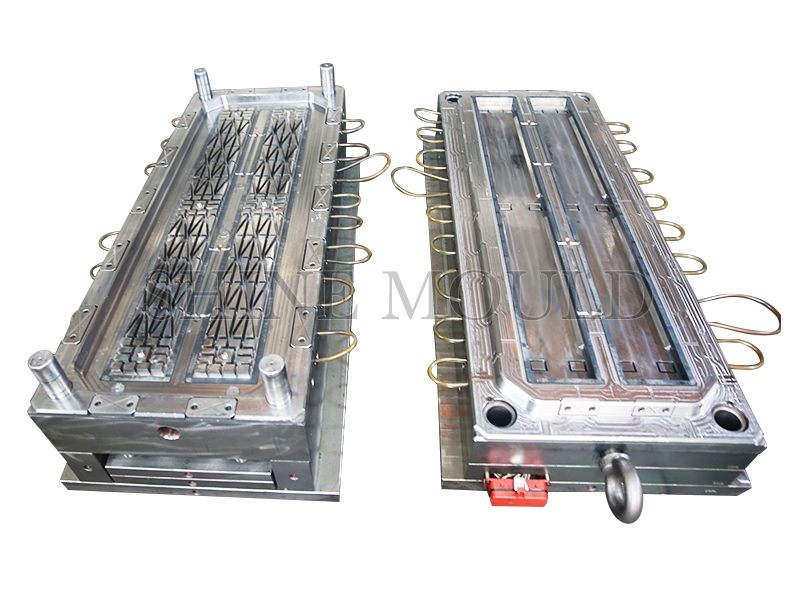

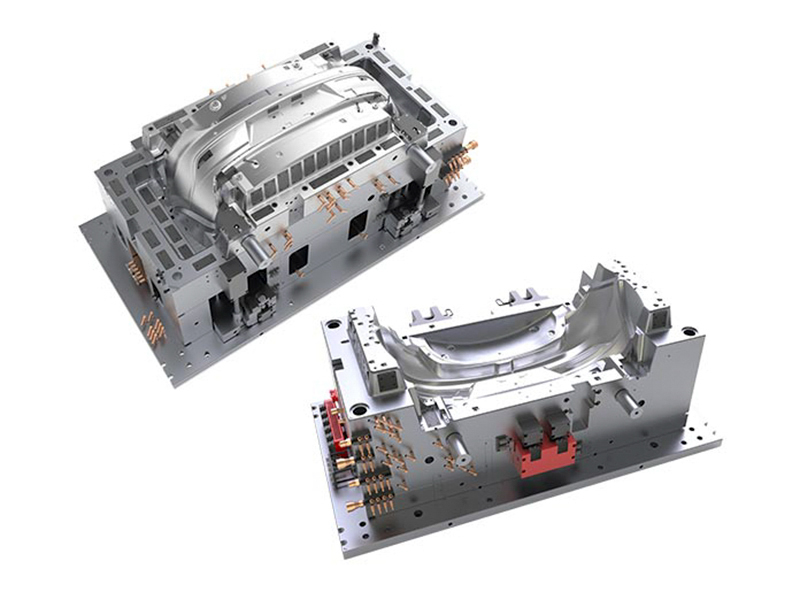

To achieve multi-color or dual-shot outcomes, the mold itself must be engineered with features like rotating cores, movable cavities, or indexing plates. These mechanisms allow different plastic materials to be injected into distinct regions of the mold without misalignment. Precise gating systems and multiple injection points are essential to avoid material bleeding and ensure crisp color separation. For example, when designing a toy with a smiling face in one color and the body in another, the gating system must direct each material to its corresponding section in good timing.

Synchronization with Specialized Injection Machines

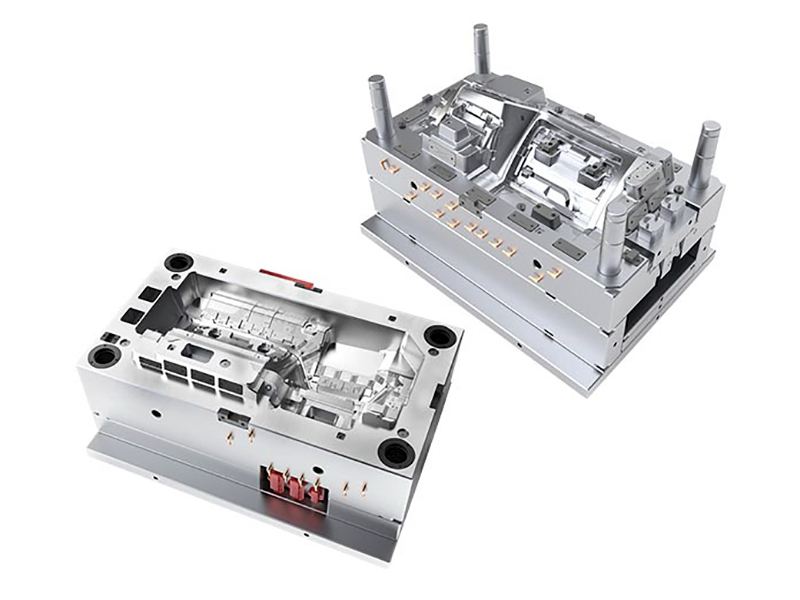

Standard injection molding machines are not suitable for multi-shot processes unless paired with specialized mold systems. In dual-shot molding, two barrels are used to inject different materials sequentially. The mold must be synchronized with the machine to allow rotation or translation between shots without causing a shift in positioning. Proper alignment ensures the materials bond correctly and the final part meets dimensional tolerances. The design of the mold must take machine compatibility into account from the early stages of development.

Thermal and Material Compatibility Considerations

In multi-color molding, each plastic component may have different flow, shrinkage, and temperature characteristics. The mold must manage these variations to prevent warping, delamination, or other defects. Heat-resistant steels and precision-cooling channels are often integrated to maintain the ideal temperature profile across all sections. Moreover, surface finishes of the mold must accommodate differences in texture or gloss, especially when one material is transparent and the other opaque.

Enhancing Product Aesthetics and Durability

One of the core advantages of dual-shot molding is its ability to enhance both the appearance and durability of toys. The integration of soft-touch grips, colorful buttons, or layered facial features adds value to the final product. Mold design must allow for tight bonding between the materials to prevent detachment during use. This is particularly critical in children's toys, where safety is paramount and components must withstand repeated handling, chewing, and impact.

Quality Control and Efficiency Gains

Molds that are optimized for multi-color injection reduce the need for manual assembly, adhesive application, or secondary operations like painting. This improves both cost-efficiency and product consistency. Automated quality inspection systems, such as in-mold sensors or vision systems, are often integrated to monitor alignment and detect flow issues in real time. A well-calibrated mold shortens cycle time while maintaining high yield rates, which is essential in mass production environments.

Search...

Search... English

English