The Benefits of Drawer Moulds in Manufacturing

Drawer moulds, also known as drawer moulds, are crucial tools in the manufacturing industry, specifically in the production of drawers for furniture, cabinets, and various storage solutions. These moulds offer a range of advantages that contribute to the efficiency and quality of the manufacturing process.

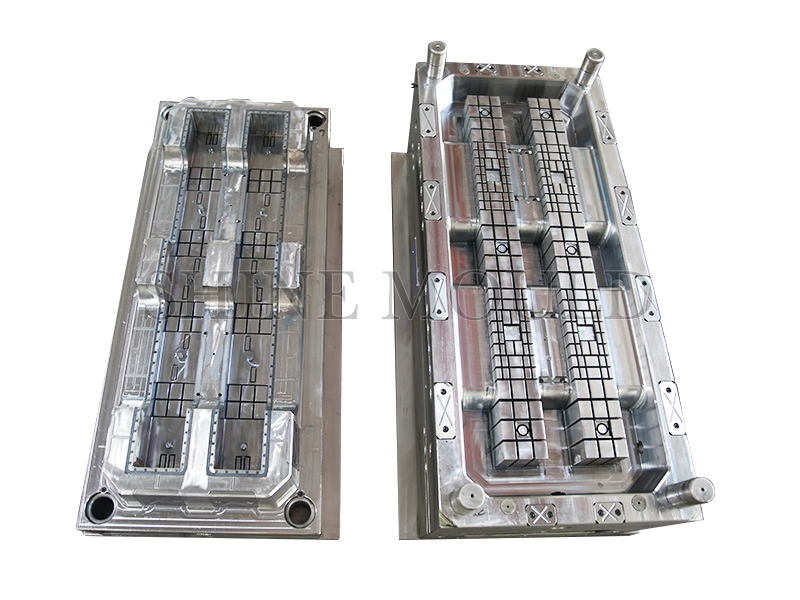

One of the primary benefits of using drawer moulds is the ability to achieve precision and consistency in the production of drawers. These moulds are designed to create the exact shape and dimensions required for drawers, ensuring that each product is uniform and meets the specified quality standards. This precision is essential for ensuring that drawers fit properly, operate smoothly, and align seamlessly in furniture and storage units.

Drawer moulds significantly improve the efficiency of manufacturing processes. When producing drawers manually, there is often a need for time-consuming adjustments and refinements to ensure uniformity and precision. Using moulds eliminates the need for such adjustments, reducing production time and labour costs. Manufacturers can produce a large number of drawers in a shorter timeframe, thus increasing overall efficiency.

Drawer moulds help minimize material waste. By ensuring that each drawer is produced with precision, there is less material wasted due to errors or misshapen components. This not only saves money but also contributes to a more environmentally sustainable manufacturing process.

The use of drawer moulds ultimately leads to cost savings for manufacturers. The increased efficiency, reduced material waste, and lower labour requirements translate into lower production costs. These cost savings can be passed on to consumers or reinvested in the business to drive innovation and growth.

Drawer moulds play a crucial role in maintaining consistent product quality. The quality of a drawer produced using a mould is highly predictable and can be closely controlled. This consistency is essential for meeting customer expectations and building a reputation for producing high-quality products.

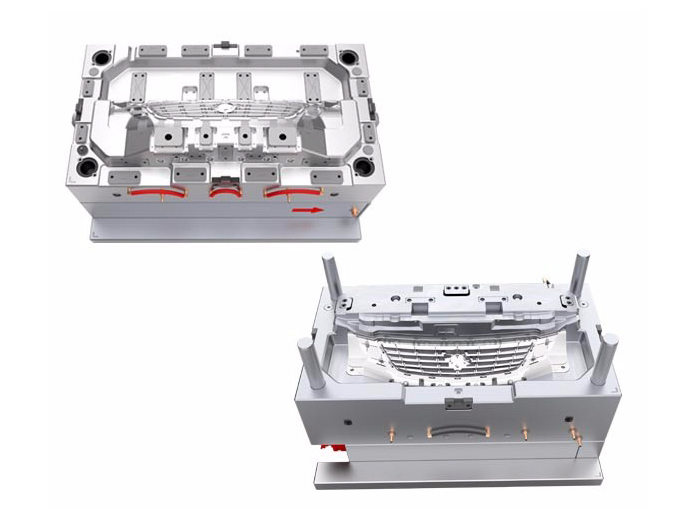

Drawer moulds can be customized to produce drawers in various shapes, sizes, and designs. This versatility allows manufacturers to cater to different customer requirements and market demands. Whether it's a small, simple drawer or a large, intricate one, the right mould can be designed and used.

Using drawer moulds significantly increases production speed and productivity. Manufacturers can produce drawers more quickly, thereby fulfilling orders in a shorter timeframe and potentially taking on more business. This can be particularly advantageous in high-demand markets or during peak seasons.

Drawer moulds can be engineered to create complex and intricate drawer designs that would be challenging to achieve through manual craftsmanship. These moulds offer the capability to produce drawers with unique shapes, decorative details, and multiple compartments.

Mould-based manufacturing allows for rigorous quality control checks. Each drawer produced using a mould can be inspected more easily and consistently for quality and accuracy. Any deviations from the required specifications can be quickly identified and rectified.

Well-maintained drawer moulds have a long service life. This durability ensures that they can be used for an extended period, providing a consistent and reliable manufacturing process over time. Manufacturers can achieve a high return on investment through the extended use of these moulds.

Drawer moulds are essential tools in the furniture and cabinetry industry, offering numerous benefits such as precision, efficiency, cost savings, and consistent quality. Their versatility and ability to produce a wide range of drawer designs make them a valuable asset to manufacturers. By utilizing drawer moulds, businesses can meet customer demands, streamline production processes, and ensure that each drawer they produce is of high quality and precision.

Search...

Search... English

English

.jpg)