The development of automobile mold industry in foreign countries

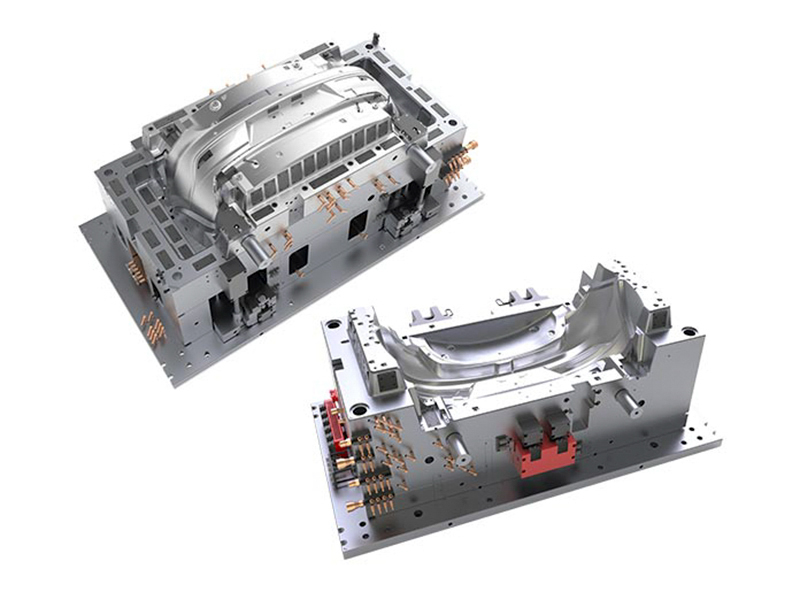

Automobile molds are important basic process equipment in the automobile industry. In automobile production, more than 90% of the parts need to be formed by molds, and 60% to 70% of the metal parts need to be formed by plastic processing. Stamping is one of the most basic, traditional, and important metal processing methods for metal plastic forming.

In the development of new models, 90% of the work is carried out around the body, and about 60% of the development cost is used for the development of the body, stamping process, and equipment. About 40% of the cost of vehicle manufacturing is used for body stamping parts and their assembly.

Major foreign automobile companies attach great importance to the development of automobile mold design and manufacturing technology. Each major automobile company has its own mold manufacturing plant to produce molds for key automotive parts, especially for main exterior parts. For example, the stamping die factory of Japan's Toyota Corporation is one of the largest and most advanced autos die manufacturing plants in the world.

Although the factory has strong mold manufacturing capabilities, it does not produce all the molds required by Toyota. It is mainly responsible for the stamping process of vehicle parts and the coordination of vehicle molds, as well as the design and manufacture of molds for major components such as interior and exterior body panels. The molds for the floor and skeleton parts are all outsourced, and the self-made mold rate is about 60%.

Specialized production is a significant feature of the automotive mold industry. A specialized division of labor is an inevitable development trend to improve production efficiency, shorten mold design and manufacturing cycles, and ensure mold product quality. The specialized production of molds makes mold enterprises more prominent in the core business of Baiji, which is conducive to accumulating rich experience in product development, production management, and service, and can provide high-quality and low-cost molds for automobile manufacturing customers in a short period of time.

Another notable feature of the development of the foreign auto mold industry is the wide application of various high-tech technologies, which has brought the design and manufacturing technology level of auto molds to an unprecedented level. These new technologies that strongly promote the rapid development of the automotive mold industry include digital mold technology, stamping process simulation, high-speed machining, automated machining, tailor-welded blank and high-strength steel plate stamping technology, and information management technology.

Search...

Search... English

English

.jpg)

.jpg)