The Impact of Sandblasting and Plating on the Touch and Feel of Toys

Surface Treatments and Their Effects on Toy Tactile Quality

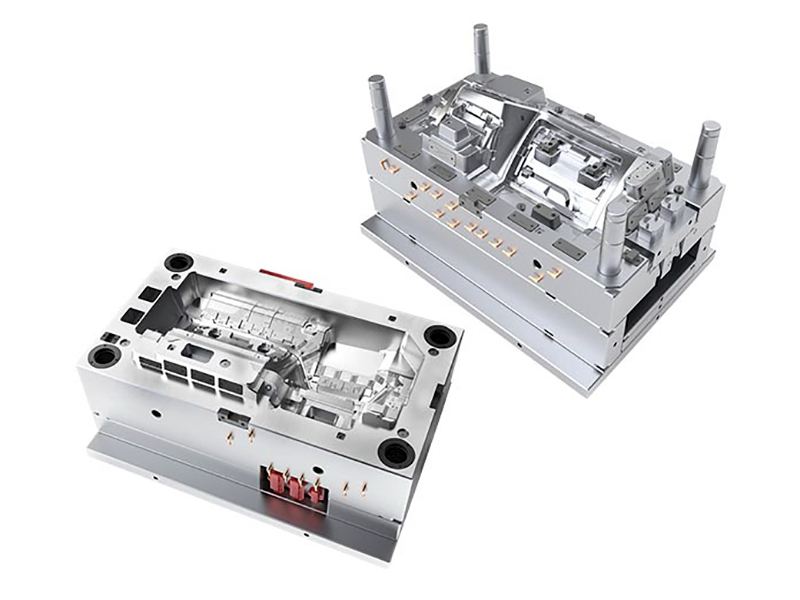

The texture and feel of a toy are just as important as its visual appeal and durability. For manufacturers, especially those using Children Toy Mould technology, surface treatment processes such as sandblasting, electroplating, polishing, and etching play a crucial role in defining the final sensory experience of a toy. While the primary purpose of moulds is to create accurate shapes, the finishing treatments applied to the mould surface directly translate into the tactile feedback children receive when handling toys.

Sandblasting is one of the common surface treatment techniques used to impart a matte, slightly roughened texture. This method involves bombarding the mould surface with abrasive particles, which creates fine indentations that are then replicated on the plastic toy surface during the injection moulding process. The resulting finish feels soft and less slippery, often preferred in toys designed for younger children. A matte surface also helps reduce visible fingerprints and smudges, maintaining a cleaner appearance during regular use. The sandblasted finish can make the toy feel more “grippable,” which is especially valuable for small hands still developing motor skills.

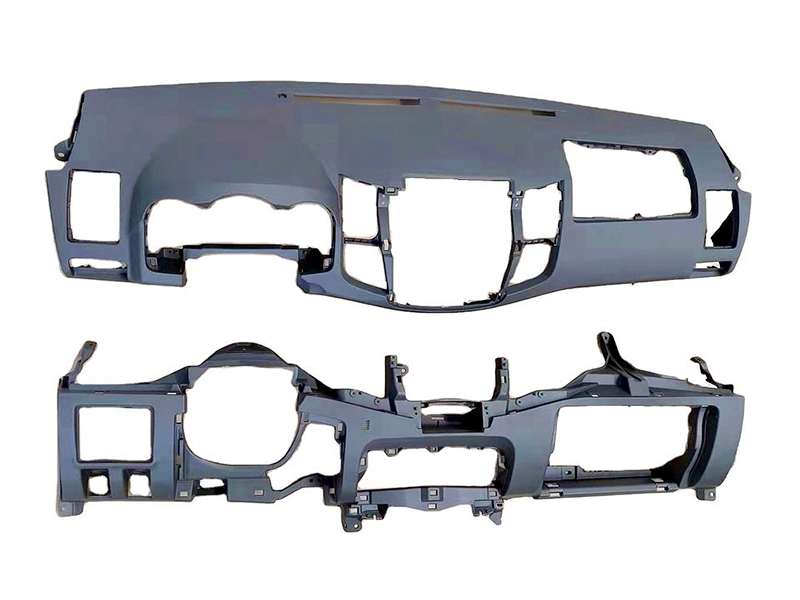

In contrast, electroplating is a process where a metallic layer is deposited on the mould surface, which can provide a mirror-like finish when transferred onto the toy. The toys produced from these highly polished moulds often have a glossy and smooth surface that feels sleek to the touch. This finish is commonly used for figurines, vehicles, and decorative components. Although it offers a premium aesthetic, such high-gloss surfaces can sometimes feel slippery or cold, depending on the material used and the ambient temperature. Moreover, smooth surfaces may highlight scratches or wear over time, slightly diminishing the product's long-term tactile quality.

Between these extremes lie a variety of other treatments like chemical etching or laser texturing, which offer precise control over micro-patterns and texture distribution. These techniques can replicate surfaces that mimic natural materials like leather, fabric, or even wood grain. This diversity allows designers to customize the toy’s feel according to age group, intended function, and even emotional impact. For example, a plush-textured handle might create a feeling of warmth and safety, while a patterned grip might be more appropriate for action toys that require active hand engagement.

The choice of surface finish also affects how children interact with toys during extended play. Smooth finishes might encourage sliding, stacking, or rolling actions, while rougher finishes offer friction that aids in gripping or sensory exploration. This is especially important for developmental toys, where texture plays a role in cognitive and sensory development. In tactile learning tools, a thoughtfully chosen surface can help stimulate touch perception and improve concentration.

Additionally, surface treatments impact how coatings, paints, or decals adhere to the toy. Matte finishes may absorb paints more evenly, causing longer-lasting colors and designs, while ultra-smooth surfaces might require primers or special adhesives. From a manufacturing standpoint, this influences not only the aesthetic quality but also the durability of the final product. Children often subject toys to rough use, so a surface that maintains both feel and appearance over time is a competitive advantage.

Lastly, safety considerations must not be overlooked. Certain surface treatments reduce the risk of sharp edges or burrs, contributing to the overall safety of the toy. A well-finished surface also resists the accumulation of dirt and bacteria, making it easier for parents to clean and maintain hygiene. In regulated markets, ensuring that surface treatments are non-toxic and hypoallergenic is a mandatory step, further reinforcing the importance of selecting the right finishing process.

Search...

Search... English

English

.jpg)