The Importance of Drawer Moulds in Custom Furniture Manufacturing

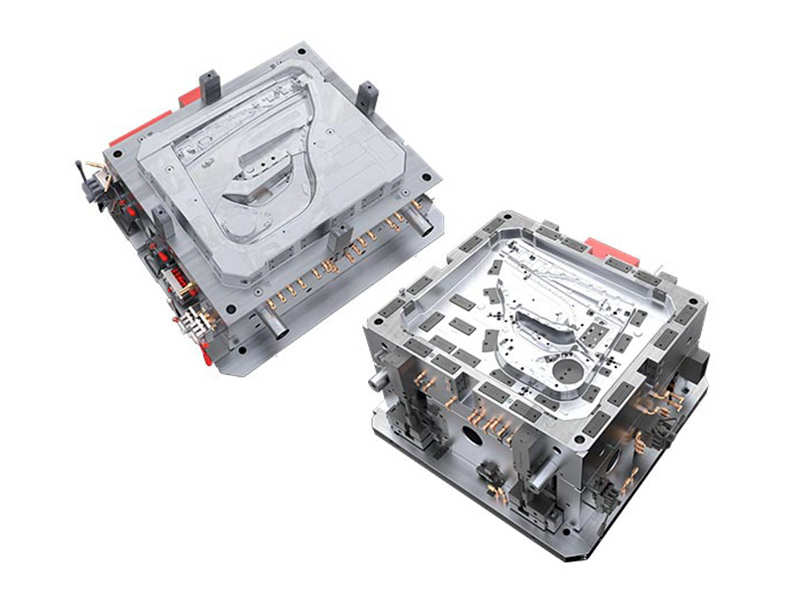

Sale OEM Small Injection Molding Drawer Blowing Plastic Mould For Sale

Drawer moulds play a crucial role in the custom furniture manufacturing process. These moulds are specially designed to shape and form the components that make up the drawers of furniture pieces, from kitchen cabinets to office desks. Understanding the importance of Sale drawer moulds can help manufacturers create high-quality, durable, and aesthetically pleasing furniture that meets the specific needs of customers.

Drawer moulds are essential for achieving precise dimensions and consistency in the production of drawer components. Custom furniture often requires a high level of accuracy to ensure that each drawer fits ideally within the designated space. The moulds allow manufacturers to produce identical parts with reduced variation, which is particularly important for custom designs that require attention to detail. This consistency in size and shape contributes to the overall functionality and visual appeal of the finished product.

In addition to precision, drawer moulds contribute to the overall strength and durability of custom furniture. By providing a consistent and uniform structure, moulds help ensure that the components are strong enough to hold up under regular use. The moulding process can also enhance the quality of the material used, as the uniform pressure applied during the moulding ensures that the drawer parts are free from weaknesses or defects. This is especially important for furniture that will be used frequently, as it ensures that the drawers function smoothly and can withstand everyday wear and tear.

Another important aspect of drawer moulds is their ability to help manufacturers achieve intricate designs. Custom furniture often includes unique details or decorative elements that require specific moulding techniques. Moulds can be designed to create these complex shapes, allowing manufacturers to incorporate custom features such as decorative handles, intricate trim, or unique drawer fronts. This adds a level of personalization to the furniture, allowing it to match the customer's specific style preferences or the design vision of the space where it will be placed.

Drawer moulds also contribute to the efficiency of the manufacturing process. Instead of manually shaping each drawer component, manufacturers can use moulds to quickly and accurately produce multiple identical parts. This not only speeds up production times but also reduces labor costs, making the process more cost-effective. In custom furniture manufacturing, where every piece is often made to order, the use of it helps ensure that production remains efficient, even when producing bespoke pieces with unique specifications.

Furthermore, drawer moulds enable manufacturers to create furniture that is both functional and visually appealing. The smooth, even surfaces that result from using high-quality ones help enhance the overall aesthetic of the furniture. Whether the goal is to create a sleek, modern look or a more traditional design, OEM Blowing Plastics provide the tools necessary to achieve the desired result. Additionally, the moulds can be used to create ideally sized compartments within the drawers, making the furniture more practical and user-friendly.

In terms of material selection, drawer moulds also allow manufacturers to work with a variety of materials, from wood to metal and composite materials. This flexibility makes it possible to create custom furniture that meets both aesthetic and functional needs. Whether the project requires lightweight materials or more robust options, Small Injection Molding For Sale ensure that the desired material is shaped and formed precisely as needed.

In conclusion, drawer moulds are an indispensable tool in custom furniture manufacturing. They provide the precision, durability, and design flexibility necessary to create high-quality, functional, and visually pleasing pieces of furniture. Whether used for basic designs or intricate, custom features, drawer moulds help manufacturers achieve the desired results in a cost-effective and efficient manner. The importance of these moulds cannot be overstated, as they are integral to producing furniture that meets the specific needs and preferences of customers.

Search...

Search... English

English

.jpg)