The Ingenious World of Laundry Basket Moulds

Laundry baskets stand as indispensable tools, streamlining the chore of organizing and transporting laundry. Behind the scenes, the production of these everyday items is made possible through the ingenuity of laundry basket molds.

Laundry basket moulds are crafted from durable and robust materials, often high-density polyethylene (HDPE) or polypropylene (PP). These materials offer resilience to wear, tear, and exposure to moisture, ensuring the longevity and durability of the final product.

Laundry basket moulds come in a variety of designs, accommodating different shapes, sizes, and styles of laundry baskets. Whether it's a traditional rectangular basket or a stackable, space-saving design, moulds can be customized to meet the diverse preferences of consumers and manufacturers.

To address the need for proper aeration and ventilation of soiled clothes, laundry basket moulds often incorporate ventilation features. These may include perforations or openings strategically placed to allow air circulation, preventing unpleasant odors and mildew.

Laundry basket moulds are engineered for efficient storage and transportation. Stackable and nestable designs ensure that baskets can be conveniently stacked when in use and nested when not in use, optimizing space in homes and during shipping.

Moulds for laundry baskets provide flexibility in color and finish options. Manufacturers can choose from a spectrum of colors to match consumer preferences or branding strategies. Additionally, various finishes, such as matte or glossy, contribute to the aesthetic appeal of the final product.

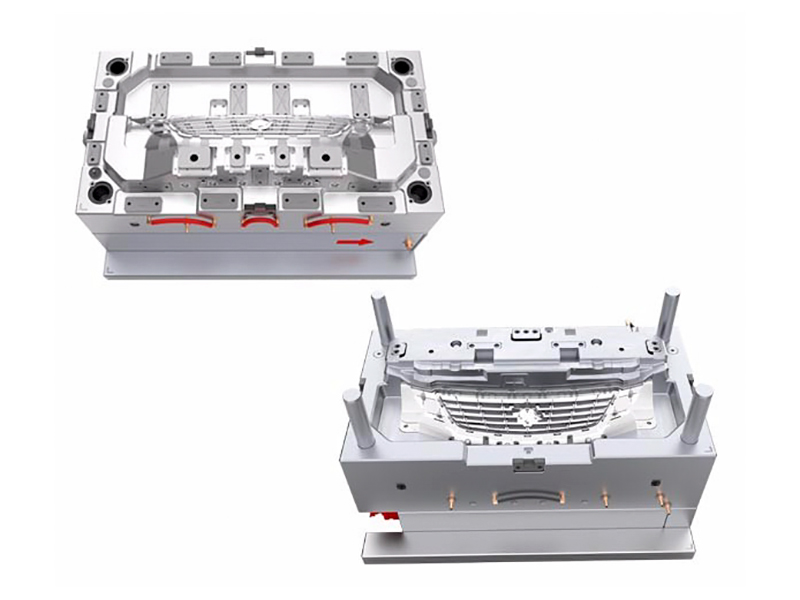

Laundry basket moulds primarily utilize the injection molding process. Molten plastic, typically HDPE or PP, is injected into the mould cavity, taking the shape of the mould. The precision of the injection molding process ensures uniform wall thickness and consistent product quality.

Laundry basket moulds often incorporate ribbed structures to enhance the strength and rigidity of the baskets. These ribs provide additional support, allowing the baskets to withstand the weight of laundry without warping or collapsing.

Ergonomics is a key consideration in laundry basket mould design. Moulds include features for handles and grips, making it easy for users to carry and transport the basket comfortably. Reinforced handles contribute to the overall durability of the product.

Laundry basket moulds offer customization options for branding purposes. Manufacturers can include logos, brand names, or other markings on the mould to create a distinct identity for their products in the market.

Laundry basket moulds play a fundamental role in providing households with essential tools for organizing and transporting laundry. The variety in designs and features caters to the diverse needs of consumers, making laundry baskets a staple in homes worldwide.

Beyond households, laundry basket moulds are utilized in commercial and industrial settings, such as laundromats, hotels, and healthcare facilities. The durability and functionality of the baskets make them suitable for heavy usage in these environments.

With the rise of online shopping, laundry baskets have found applications in e-commerce packaging. Moulds enable the production of stackable and space-efficient baskets that can be shipped conveniently, meeting the storage and organization needs of consumers.

Laundry basket moulds epitomize the marriage of form and function, providing a means to produce essential household items efficiently. From durable materials to customizable designs, these moulds contribute to the creation of versatile, stackable, and aesthetically pleasing laundry baskets that simplify the daily task of laundry management.

Search...

Search... English

English

.jpg)

.jpg)