The Manufacturing Process Behind an Armchair Mould

The production of durable and reliable furniture components requires precision, especially when it comes to creating moulds. Among these, the Armchair Mould plays a significant role in the furniture industry, providing the necessary form for producing consistent, high-quality armchairs. The manufacturing process behind an Armchair Mould involves several stages, each contributing to the final product’s functionality and performance.

It all begins with design. Before any physical work starts, a team of designers and engineers collaborates to develop a detailed blueprint of the Armchair Mould. This stage takes into account various factors such as chair dimensions, armrest curves, seat depth, and backrest angles. The design process ensures the Mould will meet the requirements for both aesthetics and user comfort, as well as for efficient production.

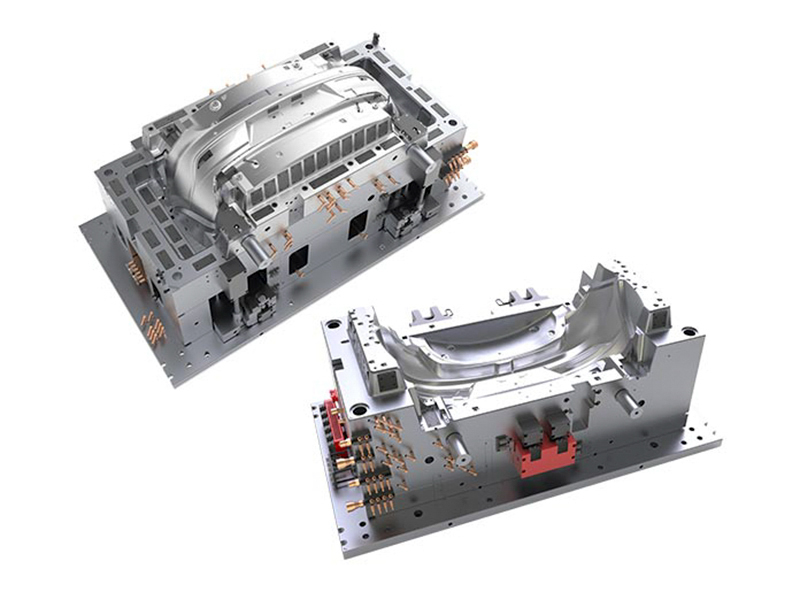

Once the design is approved, the next step is selecting suitable materials. The choice of material for an Armchair Mould typically depends on the type of chair being manufactured and the production method to be used. Common materials for a Mould include high-grade steel and aluminium alloys, known for their durability and resistance to wear. The material selection process ensures that the Mould will maintain its shape and functionality through repeated use.

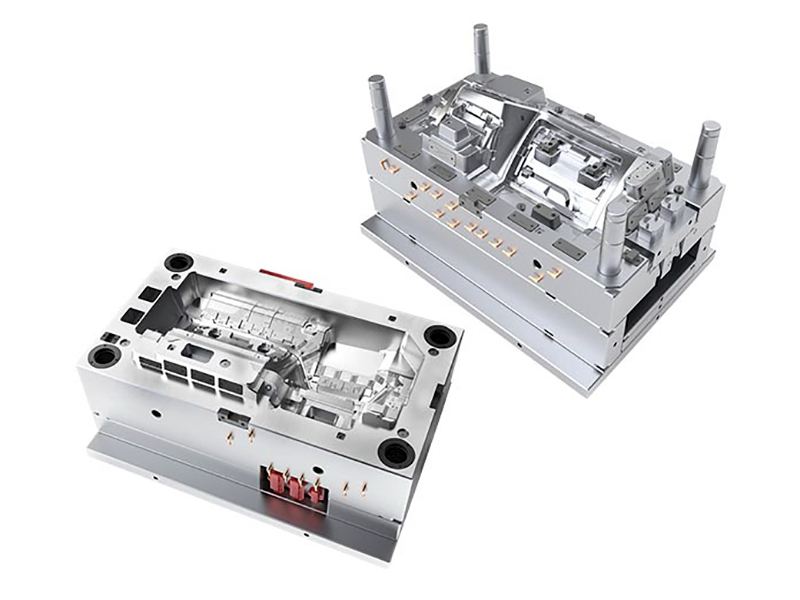

The machining process follows material selection. In this phase, the raw material is cut and shaped into the basic form of the Armchair Mould using a combination of CNC (computer numerical control) machines, milling, and turning tools. CNC machines are particularly useful for achieving the intricate details often required for armrest designs and backrest contours. Throughout this process, precision is crucial to ensure that every component of the Mould fits together seamlessly.

After rough machining, the semi-finished Mould undergoes a series of fine-tuning processes. This involves grinding, polishing, and adjusting the surfaces to achieve the desired texture and dimensions. Fine-tuning ensures that the final chair products produced using the Mould will have a smooth finish and consistent appearance. Special attention is given to areas such as the armrests and seat surface, where user comfort is essential.

Next comes the assembly stage, where multiple mould components are combined to form the complete Armchair Mould. Many moulds are designed as two or more interlocking parts to facilitate easy removal of the finished product. During assembly, technicians carefully check the alignment and secure all components in place. A properly assembled Mould ensures efficient production and reduces the risk of defects during the moulding process.

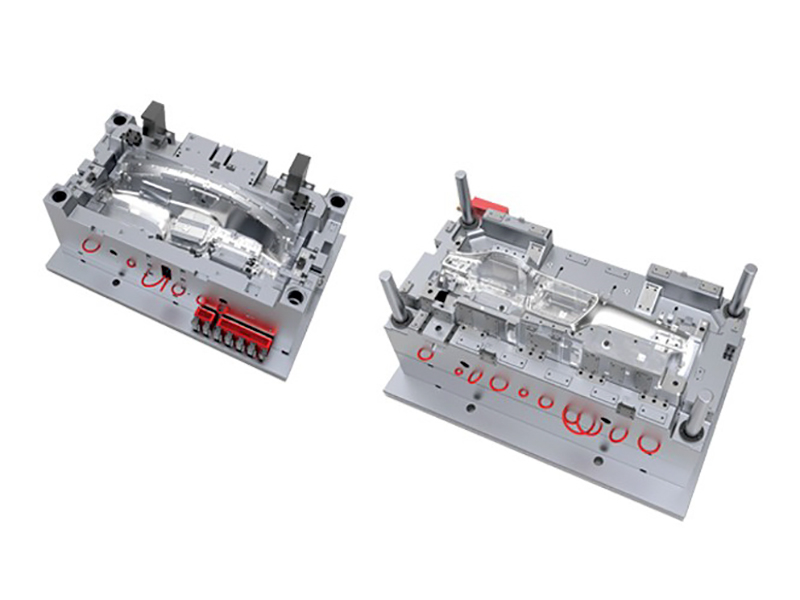

Before the Armchair Mould is ready for mass production, it undergoes a series of testing procedures. These tests typically involve trial moulding runs using the actual materials intended for the final armchairs, such as plastic, fibreglass, or polyurethane foam. The testing phase allows manufacturers to identify any issues with the Mould’s shape, alignment, or surface finish and make necessary adjustments.

Surface treatment is another critical step in the manufacturing process. To prolong the lifespan of the Armchair Mould and improve its performance, protective coatings such as chrome plating or specialised finishes may be applied. These treatments help reduce surface wear, prevent corrosion, and make the mould easier to clean after each production cycle. By applying these treatments, manufacturers can ensure that the Mould remains in ideal working condition over time.

Once the Armchair Mould passes all tests and surface treatments, it moves on to the final inspection stage. Experienced quality control technicians examine the mould to confirm that it meets all required specifications. This includes checking dimensions, surface smoothness, and structural integrity. Only after passing this final inspection is the Mould considered ready for operational use.

In the production phase, the Armchair Mould is used in conjunction with various moulding techniques depending on the material of the armchair being produced. Common methods include injection moulding for plastic chairs, compression moulding for composite materials, or rotational moulding for larger, hollow designs. The Mould is subjected to heat, pressure, or rotational force to shape the raw material into the final chair form.

Search...

Search... English

English

.jpg)

.jpg)

.jpg)