The Role of Advanced Materials in Modern Bucket Mould Manufacturing

As the demand for plastic buckets grows across different industries, manufacturers are continually searching for ways to improve the efficiency, durability, and precision of their moulds. At the heart of this improvement lies the smart use of advanced materials. In the field of Bucket Mould production, the choice of materials directly influences the quality of the final product, the mould’s lifespan, and overall production efficiency.

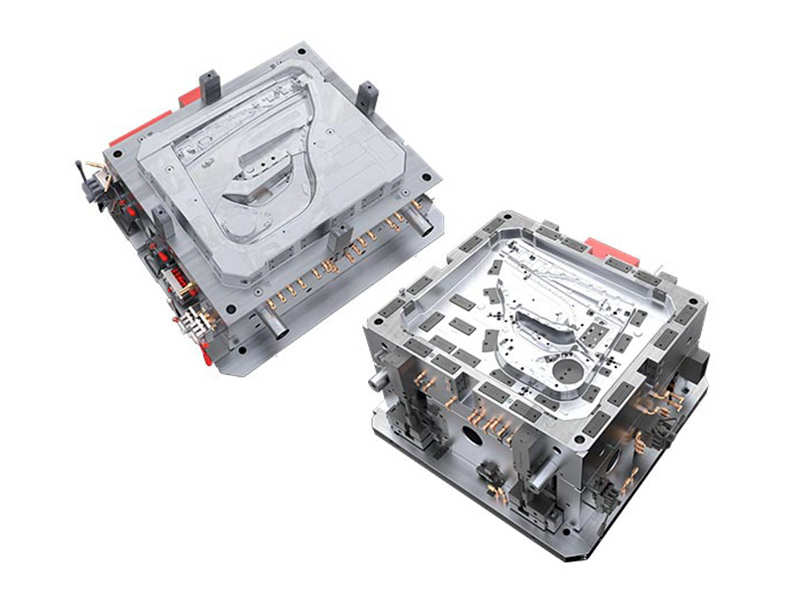

A Bucket Mould undergoes intense pressure, heat, and repeated use in a typical injection molding environment. The materials chosen for creating the mould must be able to handle these demands while maintaining accuracy and resisting wear over time. Using the right material means fewer breakdowns, consistent product quality, and a longer service life for the mould.

One of the widely used materials in Bucket Mould manufacturing is high-grade tool steel. This material is known for its strength, toughness, and ability to maintain its shape even after many injection cycles. Some manufacturers also turn to specialized hardened steel, which provides greater resistance against abrasion and corrosion, especially when working with abrasive plastics or additives.

Another option in modern Bucket Mould making is stainless steel. While it may not be as hard as tool steel, stainless steel offers good corrosion resistance and is easier to polish, making it ideal for products that require a smooth finish.

Certain Bucket Mould designs may also incorporate materials like beryllium copper in specific areas, such as cores and inserts. This material is appreciated for its outstanding thermal conductivity, which helps speed up the cooling process during production and shortens cycle times.

Besides the base material of the Bucket Mould, surface coatings play an essential role in extending mould life and improving product quality. Advanced coatings such as nitriding, chrome plating, and PVD (physical vapour deposition) coatings are increasingly popular in modern mould-making.

These coatings help reduce surface friction, making it easier to release the finished product from the mould. They also offer added protection against corrosion and wear, which is particularly useful for Bucket Mould applications involving frequent use or exposure to harsh materials.

Using advanced materials doesn’t just improve mould durability — it also enhances production efficiency. A Bucket Mould made with high-performance materials can maintain consistent product quality over long runs, reducing the need for adjustments or repairs.

Better thermal conductivity, as found in certain alloys and beryllium copper, allows for quicker cooling times. Faster cooling reduces overall cycle times, which means more products can be made in less time without sacrificing quality. This efficiency is especially important in high-volume production lines where even small time savings per cycle add up quickly.

Another key advantage of advanced materials in Bucket Mould manufacturing is improved product consistency. High-quality materials resist deformation and wear, maintaining their precision over thousands of production cycles. This means each bucket produced retains the same shape, wall thickness, and finish, which is critical in industries where uniformity matters.

As sustainability becomes a growing concern for manufacturers, advanced materials contribute to more responsible production practices. A durable Bucket Mould made from long-lasting materials reduces the frequency of mould replacements, cutting down on material waste.

Additionally, materials with better thermal conductivity help reduce energy consumption during the injection process by shortening cooling times. These small improvements can result in noticeable energy savings over time, supporting more efficient and environmentally conscious manufacturing operations.

The use of advanced materials has become an essential part of modern Bucket Mould manufacturing. From tool steel and stainless steel to beryllium copper and protective coatings, these materials help improve mould durability, production efficiency, and product consistency.

As customer expectations and industry standards continue to evolve, Bucket Mould manufacturers that invest in high-performance materials will be better equipped to meet these demands. Not only do these materials enhance the quality of the finished product, but they also help manufacturers streamline their operations and adopt more sustainable production practices.

Search...

Search... English

English

-1.jpg)