The Role of Automotive Mould in Automotive Manufacturing

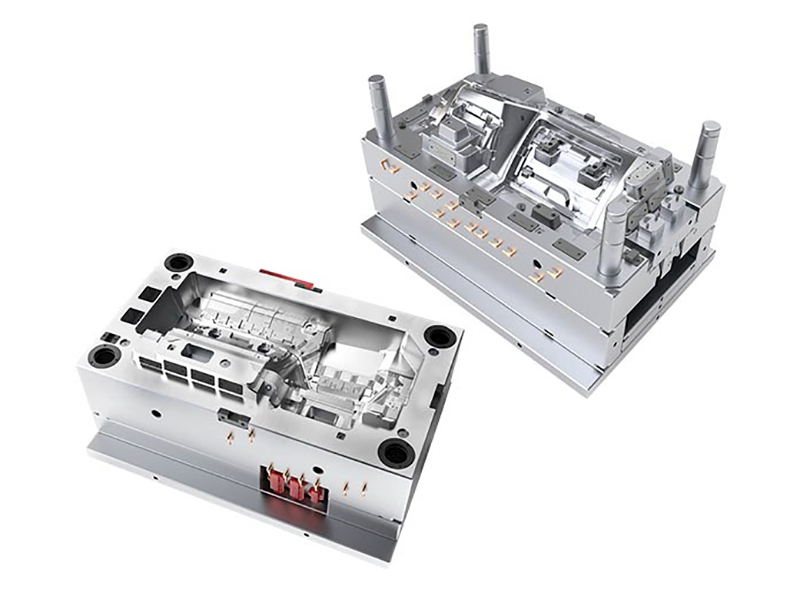

The automotive industry is a global powerhouse, producing millions of vehicles every year, each comprised of thousands of components. At the heart of automotive manufacturing lies the critical role of automotive moulds. These moulds are responsible for shaping and creating the various parts and components that make up a vehicle.

Automotive moulds are engineered with meticulous precision. They are essential for shaping components that must fit together seamlessly, whether it's the intricate design of an interior dashboard panel or the exact specifications of an engine part. Precision is a non-negotiable aspect in automotive manufacturing, where even minor deviations can lead to problems in the performance, safety, and aesthetics of the final product.

The choice of materials is crucial in automotive manufacturing, and automotive moulds enable the use of a wide range of materials, from plastics and composites to metals. The material used in the moulds directly affects the properties of the components produced, such as weight, strength, and durability. For example, lightweight materials can improve fuel efficiency, while high-strength materials can enhance safety.

Automotive moulds offer remarkable design flexibility. They can be customized to meet the unique requirements of each vehicle model. Whether it's a luxury car with intricate interior components or a heavy-duty truck with robust exterior parts, automotive moulds provide the flexibility to create parts that align with the design and functional specifications of each vehicle.

Automotive moulds play a significant role in reducing manufacturing costs. The molds are built for efficiency, allowing for rapid production and lower per-unit costs. Automation in moulding processes also reduces labour costs and minimizes the risk of human error. This efficiency contributes to the overall cost-effectiveness of automotive manufacturing.

Automotive manufacturers produce vehicles in large quantities. Consistency is vital to ensuring that each vehicle component is identical in terms of size, shape, and quality. Automotive moulds provide this level of consistency, which is critical for assembly line efficiency and overall product reliability.

In the fast-paced automotive industry, time is of the essence. Automotive moulds facilitate rapid prototyping and testing, allowing manufacturers to create and test components quickly. This not only speeds up the product development cycle but also enables manufacturers to make design modifications on the fly, ensuring that the final product meets all requirements.

Sustainability is a growing concern in the automotive industry. Automotive moulds align with these environmental goals by minimizing material waste. The process is highly efficient, and any excess material can be recycled or reused, reducing the environmental impact and lowering material costs for manufacturers.

Automotive components must withstand the rigours of everyday use, from harsh weather conditions to mechanical stress. Automotive moulds produce parts that are robust and durable, ensuring that vehicles can perform reliably over their lifespan. This durability is essential for the longevity and safety of automobiles.

Automotive moulds are the unsung heroes of automotive manufacturing, playing a pivotal role in shaping the components that makeup vehicles. Their precision engineering, material versatility, customization capabilities, efficiency, consistency, rapid prototyping, sustainability, and focus on durability are critical for producing high-quality and reliable vehicles. As the automotive industry continues to evolve and strive for innovation and sustainability, automotive moulds will remain a cornerstone of the manufacturing process, ensuring that vehicles are not only safe and reliable but also environmentally responsible and cost-effective. Their adaptability and precision are essential for keeping the wheels of the automotive world turning.

Search...

Search... English

English

.jpg)

.jpg)