The Role of Basket Mould in Modern Plastic Injection Moulding Factories

In today’s competitive manufacturing environment, plastic injection moulding factories play a vital role in supplying products for various industries, including household goods, agriculture, logistics, and retail. Among the many tools used in these factories, the Basket Mould holds a unique and important position. This mould is responsible for shaping plastic baskets, which are widely used for storage, transport, and display purposes in daily life and industrial applications.

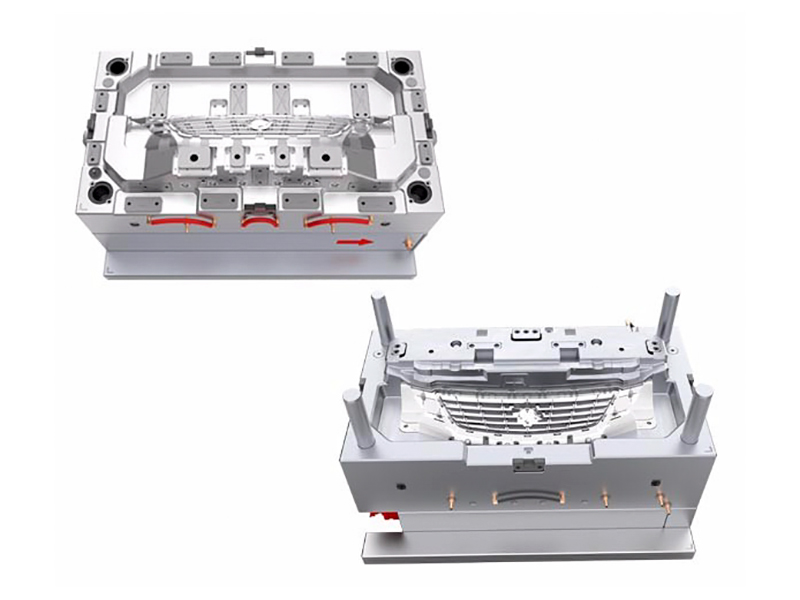

A Basket Mould is a specialised tool designed to form baskets of different shapes and sizes from molten plastic. It is fitted into an injection moulding machine, where plastic material is heated, injected into the mould cavity, and cooled to form the desired product. The mould determines the size, structure, wall thickness, and surface texture of the final basket. In modern factories, it has become an essential piece of equipment for producing high-quality and durable plastic baskets that meet market demands.

One of the main reasons for the popularity of the Basket Mould in plastic factories is its ability to support high-volume production. As plastic baskets are used in large quantities across various industries, manufacturers require moulds that can deliver consistent results over extended production cycles. A well-made mould enables factories to maintain stable product quality while meeting tight delivery schedules.

Modern injection moulding factories value the precision offered by the Basket Mould. Every detail, from the basket’s shape to its handle design and ventilation holes, depends on the mould’s accuracy. High-precision moulds reduce the risk of product defects such as uneven edges, warping, or improper fitting. This is especially important for factories supplying baskets to industries where consistency and reliability are critical.

The role of the Basket Mould extends beyond basic production; it also contributes to improving factory efficiency. A well-designed mould incorporates advanced cooling systems and ejection mechanisms, helping to reduce cycle times and simplify product removal. Faster production cycles mean higher output rates, which allow factories to increase their capacity without significant changes to equipment or staffing levels.

Flexibility is another advantage provided by the Basket Mould in modern factories. Manufacturers often need to produce a variety of basket types, from small storage containers to large, heavy-duty bins. By using interchangeable inserts or modular mould designs, a single Basket Mould can be adapted to create different products. This versatility helps factories respond to market trends and customer requests more quickly.

Durability is an important characteristic of any Basket Mould used in industrial settings. Moulds are exposed to high temperatures, strong injection pressures, and continuous operation. A durable mould resists wear and deformation, providing long service life and reducing the need for frequent maintenance or replacement. This durability benefits factories by lowering operational costs and reducing downtime.

Another significant role of the Basket Mould in modern factories is its contribution to environmental goals. As more businesses adopt sustainable practices, the demand for recyclable and eco-friendly plastic products is increasing. The mould must be capable of handling new types of plastic materials, such as bio-based resins or recycled polymers. Factories using moulds that work efficiently with these materials can reduce waste and offer products that align with current environmental expectations.

Automation has become a standard feature in many plastic injection moulding factories, and the Basket Mould plays a part in supporting these automated systems. Moulds that integrate smoothly with robotic arms and automated product handling systems help streamline production lines. This improves operational safety, reduces labour costs, and maintains steady production speeds. A factory equipped with automation-friendly mould solutions can stay competitive in a fast-changing market.

Quality control is a key priority in modern factories, and the Basket Mould contributes directly to achieving this goal. By producing baskets with consistent dimensions, smooth surfaces, and uniform structural strength, the mould ensures that every product meets quality standards. This reduces the risk of product recalls and customer complaints while enhancing the factory’s reputation in the market.

Search...

Search... English

English

.jpg)

.jpg)

.jpg)