The Significance of Automotive Moulds

In the ever-evolving landscape of automotive manufacturing, one crucial element has played a pivotal role in the automotive mould. With the constant demand for innovative designs, precision engineering, and efficient production processes, automotive moulds have emerged as the unsung heroes shaping the vehicles we drive today. This article delves into the world of automotive moulds, highlighting their significance, evolution, and impact on the automotive industry.

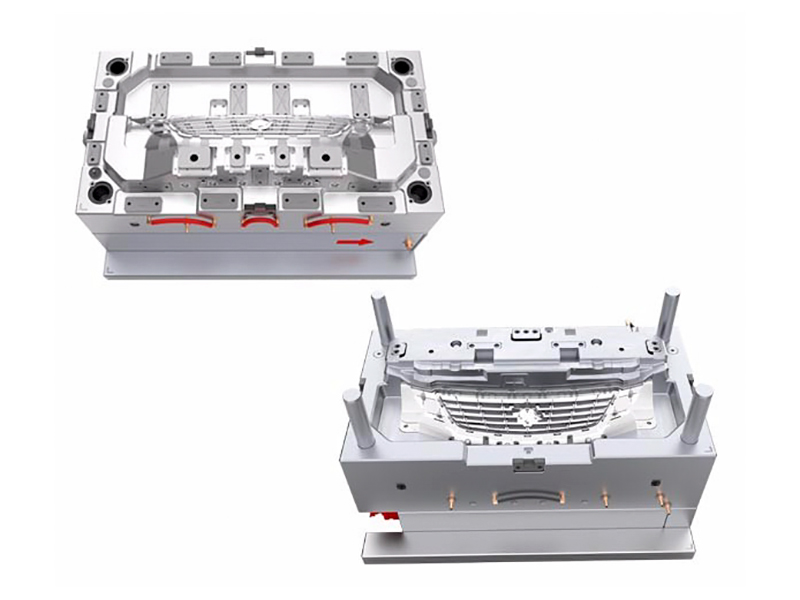

Automotive moulds, also known as molds, are intricate tools used in the production of vehicle components. These moulds are responsible for shaping and forming various parts of an automobile, ranging from the exterior body panels to interior components. Their precision and accuracy are essential in ensuring that each component meets the exact specifications required for optimal performance and safety.

Over the years, automotive mould technology has witnessed remarkable advancements. Early moulds were often made from materials like wood or metal, requiring extensive manual labour and limited design possibilities. However, with the advent of computer-aided design (CAD) and computer-aided manufacturing (CAM) technologies, the process underwent a transformation.

Modern automotive moulds are typically created using advanced materials such as high-strength steel, aluminium, or even composite materials. These materials offer enhanced durability, precision, and the ability to produce complex shapes that were once thought to be impossible. Computer simulations and virtual prototyping have become integral to the mould design process, enabling engineers to test and refine their designs before actual production.

The utilization of automotive moulds has revolutionized the efficiency of vehicle production. Mass production techniques, enabled by these moulds, have significantly reduced production times and costs, making vehicles more affordable and accessible to a wider consumer base. The repetitive nature of mould-based manufacturing ensures consistency and quality across each produced component, contributing to the overall reliability of the final product.

While automotive moulds have greatly facilitated mass production, they have not hindered the industry's drive for innovation and customization. Modern moulding technologies allow for rapid tooling changes, enabling manufacturers to adapt to evolving design trends and consumer preferences. This flexibility has led to the production of vehicles with diverse aesthetics, features, and functionalities, catering to a wide range of consumer demands.

Despite the numerous advantages offered by automotive moulds, challenges persist. The initial investment in mould design and fabrication can be substantial, particularly for specialized components. Additionally, the shift towards electric and autonomous vehicles presents new challenges, as the designs and components required for these vehicles differ significantly from those of traditional internal combustion engine vehicles.

Looking ahead, the automotive industry is poised to witness further innovations in moulding technology. Additive manufacturing, commonly known as 3D printing, has shown promise in producing complex moulds with reduced lead times. Furthermore, the integration of artificial intelligence and machine learning into the design and optimization of moulds could enhance their efficiency and performance.

In conclusion, automotive moulds have emerged as indispensable tools in the automotive manufacturing process. Their evolution from rudimentary forms to highly advanced, computer-aided designs has revolutionized the industry, enabling efficient mass production, design flexibility, and customization. As the automotive landscape continues to evolve, so too will the role of moulds, driving innovation and shaping the vehicles of the future.

Search...

Search... English

English