The Significance of Drawer Moulds in the Furniture Industry

Drawer molds are key tools used in the manufacture of drawers, through precise design and manufacture, consistent quality and precise specifications of drawer products are achieved. Molds are made of durable materials to withstand repeated use and ensure long-lasting durability. During the manufacturing process of the drawer mould, molten plastic is injected into the mold cavity, and after cooling and solidification, the mold is opened to release the formed drawer. The use of drawer molds brings several advantages, including cost-effective mass production, consistent end-product quality, design flexibility, and sustainable manufacturing. They play an important role in the furniture manufacturing industry, meeting market demands, driving production efficiency, and providing functional and aesthetic storage solutions.

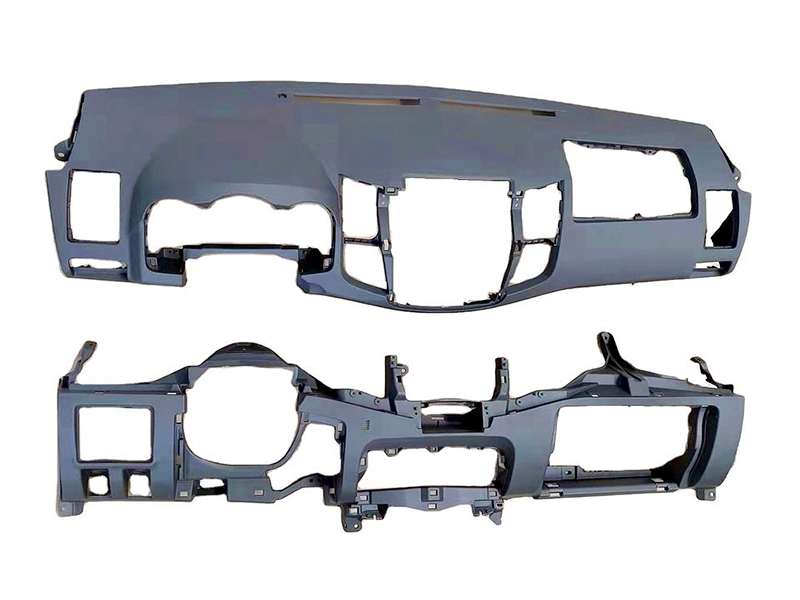

Drawer moulds play a crucial role in the manufacturing of drawers, providing the means to create functional and aesthetically appealing storage solutions. These moulds are carefully designed and constructed to produce drawers of consistent quality and precise specifications.

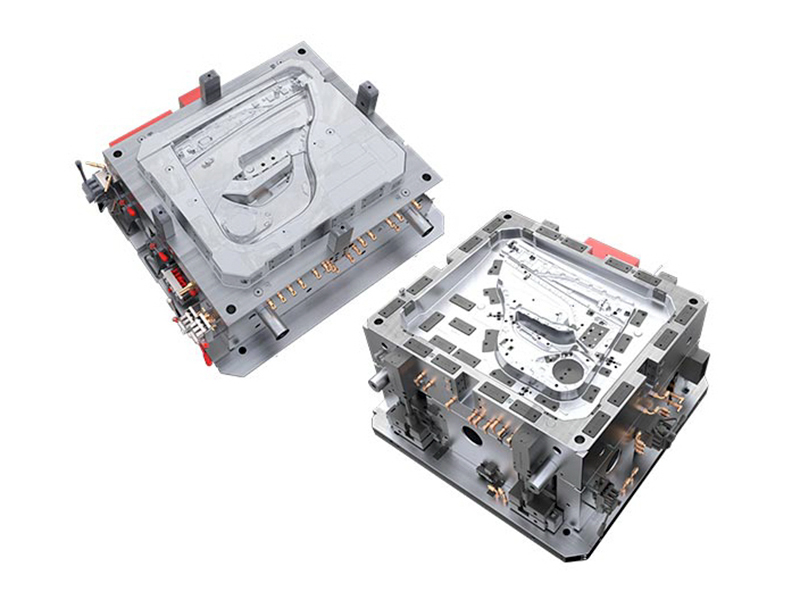

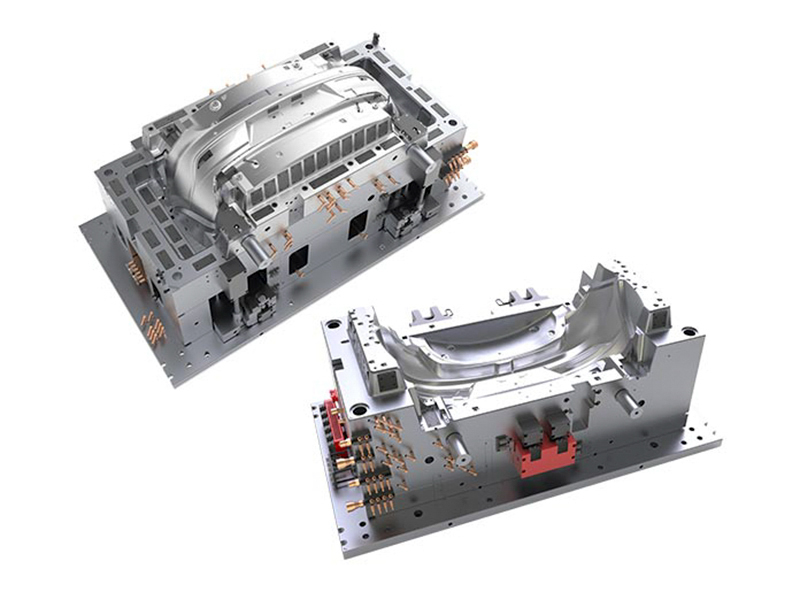

Made from durable materials such as steel or aluminium, drawer moulds are built to withstand the demands of repeated use and ensure longevity. The moulds are meticulously crafted to replicate the desired drawer design, including details such as drawer fronts, handles, and grooves. This precision engineering guarantees that each drawer produced will have the same shape, size, and dimensions, ensuring uniformity in the final product.

The manufacturing process using drawer moulds involves injecting molten plastic into the mould cavity, allowing it to cool and solidify. Once hardened, the mould is opened, and the drawer is released. This repeatable process allows manufacturers to produce drawers in large quantities efficiently, meeting market demand.

Drawer moulds offer several advantages in the furniture industry. Firstly, they enable cost-effective mass production, allowing manufacturers to produce drawers in large volumes, reducing production costs and ensuring availability. Secondly, drawer moulds ensure consistency in the final product, with every drawer having the same dimensions and fitting seamlessly into furniture units.

Furthermore, drawer moulds allow for design flexibility. Manufacturers can customize the moulds to create drawers with different styles, finishes, and features. This adaptability ensures versatility and allows businesses to cater to diverse customer preferences, offering a wide range of drawer options for various furniture applications.

In addition to their functional benefits, drawer moulds contribute to sustainability efforts. Many moulds are designed with energy-efficient features that minimize waste and optimize material usage. This eco-friendly approach aligns with the growing focus on sustainable manufacturing practices and reduces the environmental impact of production processes.

The use of drawer moulds also enhances productivity. With the ability to produce drawers in large quantities and consistent quality, manufacturers can streamline their operations and meet customer demand efficiently. This increased productivity translates into faster turnaround times and improved customer satisfaction.

In conclusion, drawer moulds are indispensable tools in the furniture manufacturing industry. With their precision engineering, durability, design flexibility, and contribution to sustainability, these moulds enable cost-effective mass production of high-quality drawers. They play a critical role in meeting market demand, ensuring consistency in product offerings, and driving efficiency in furniture manufacturing processes. As the furniture industry continues to evolve, drawer moulds will remain vital in delivering functional and aesthetically pleasing storage solutions.

Search...

Search... English

English

.jpg)

.jpg)