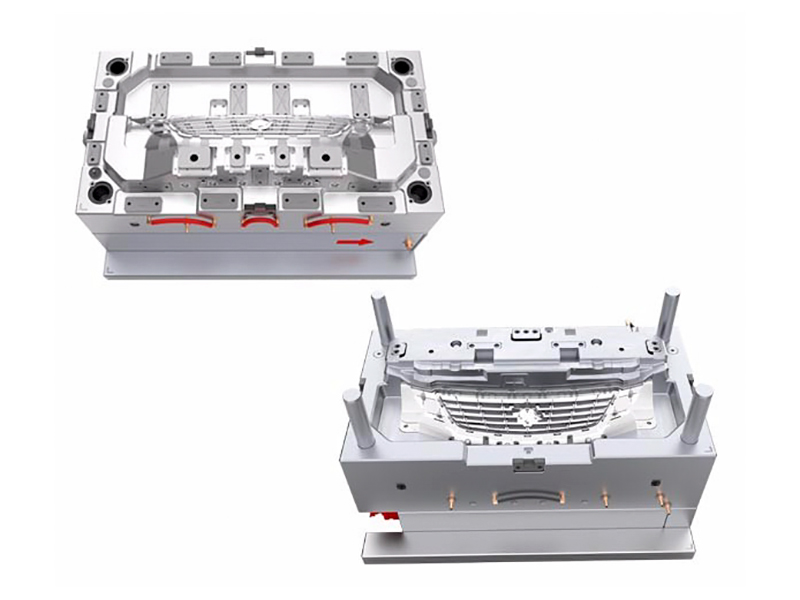

Understanding Basket Mould Structure and Functional Components

Introduction to Basket Mould Design

A Basket Mould is a specialized injection mould used to manufacture plastic baskets for household, industrial, agricultural, and commercial applications. Because baskets often feature complex hollow structures, perforated walls, and reinforced ribs, their moulds must be carefully engineered to ensure dimensional accuracy, strength, and efficient production. Understanding the basic structural components of such a mould helps manufacturers improve product quality, reduce defects, and extend mould service life. Each part of the mould plays a distinct role in shaping, cooling, and ejecting the final plastic basket.

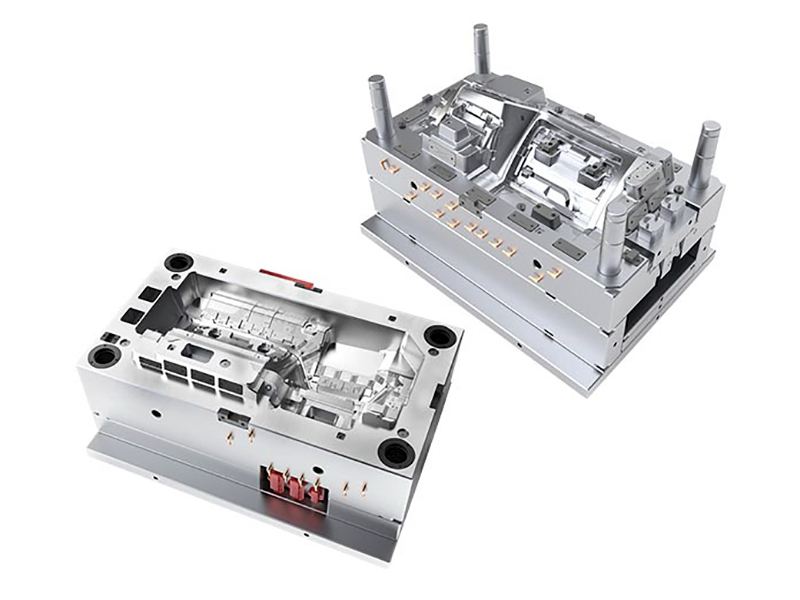

Mould Base and Support Structure

The mould base forms the foundation of the entire mould assembly. It supports all internal components and ensures alignment during the injection process. Typically made from hardened steel, the mould base absorbs clamping force from the injection molding machine and maintains structural stability under high pressure and temperature. Proper rigidity of the mould base is essential, as any deformation can cause misalignment, causing flashing or uneven wall thickness in the finished basket.

Cavity and Core System

The cavity and core are the critical parts of a basket mould because they directly define the shape and surface quality of the plastic basket. The cavity forms the external surface, while the core shapes the internal structure. Since baskets often include holes and grid-like designs, the core is usually complex and requires precise machining. High-quality surface finishing on both cavity and core ensures smooth demolding and a consistent appearance. Their accuracy directly impacts the dimensional precision and load-bearing capacity of the final product.

Runner and Gate System

The runner and gate system is responsible for delivering molten plastic from the injection machine nozzle into the mould cavity. The runner channels guide the material flow, while the gate controls how the plastic enters the cavity. For basket moulds, proper gate placement is essential to ensure uniform filling, especially for large or perforated designs. A well-designed runner and gate system reduces flow resistance, reduces weld lines, and helps prevent defects such as short shots or uneven filling.

Cooling System

The cooling system plays a vital role in controlling cycle time and product quality. Cooling channels are strategically placed within the mould to remove heat from the molten plastic after injection. Effective cooling ensures that the basket solidifies evenly, reducing internal stress and deformation. Since baskets often have varying wall thicknesses, balanced cooling is particularly important. An optimized cooling system improves productivity while maintaining consistent part dimensions and mechanical strength.

Ejection System

Once the plastic basket has cooled and solidified, the ejection system removes it from the mould. This system typically includes ejector pins, ejector plates, and return mechanisms. For basket moulds, careful ejection design is essential to avoid deformation or surface damage, especially because baskets are relatively large and may have thin walls. Uniform ejection force helps release the product smoothly, maintaining its shape and structural integrity during removal.

Ventilation and Air Release Components

Ventilation components allow trapped air to escape from the mould cavity during injection. Proper venting is particularly important for basket moulds due to their intricate structures and multiple ribs. If air cannot escape efficiently, defects such as burn marks or incomplete filling may occur. Well-designed vents ensure smooth material flow and improve surface quality, contributing to consistent and reliable production.

The structural design of a basket mould is a carefully coordinated system in which each component serves a specific and essential function. From the mould base that provides stability to the cavity and core that defines product shape, every part contributes to efficient and high-quality manufacturing. The runner, cooling, ejection, and ventilation systems work together to ensure proper material flow, solidification, and product release. By understanding these basic components and their roles, manufacturers can optimize mould performance, reduce defects, and produce durable, well-formed plastic baskets suitable for a wide range of applications.

Search...

Search... English

English

.jpg)

.jpg)