Understanding the Risk of Deformation and Cracking in Basket Moulds

Heat treatment is a critical stage in the manufacturing of Basket Mould, significantly affecting its mechanical properties and overall durability. During this process, metal components are subjected to elevated temperatures, followed by controlled cooling, to enhance hardness, strength, and wear resistance. However, the very nature of heat treatment can introduce stress within the mould material, potentially causing deformation or even cracking if not carefully managed. The complexity of mould geometry, combined with thermal expansion and contraction, creates conditions that must be carefully monitored to maintain precision and functionality.

Material Properties and Thermal Stress

The likelihood of deformation or cracking is heavily influenced by the type of material used in mould construction. High-carbon steels and alloy steels are commonly selected for their hardness and durability, yet these materials are also more susceptible to thermal stress during heating and quenching. As the metal is rapidly heated or cooled, uneven expansion and contraction can produce internal stresses, causing warping or surface cracks. Understanding the material’s thermal conductivity, hardness profile, and phase transformation behavior is essential for predicting and mitigating these risks.

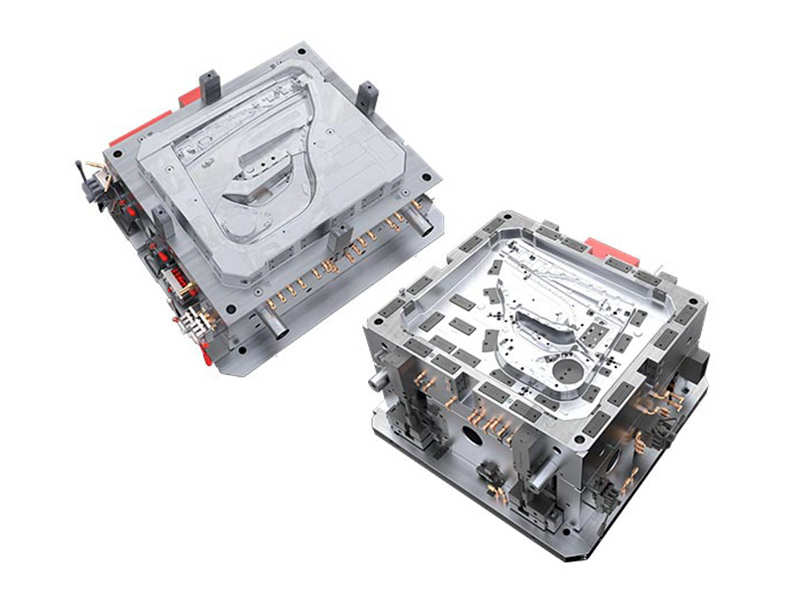

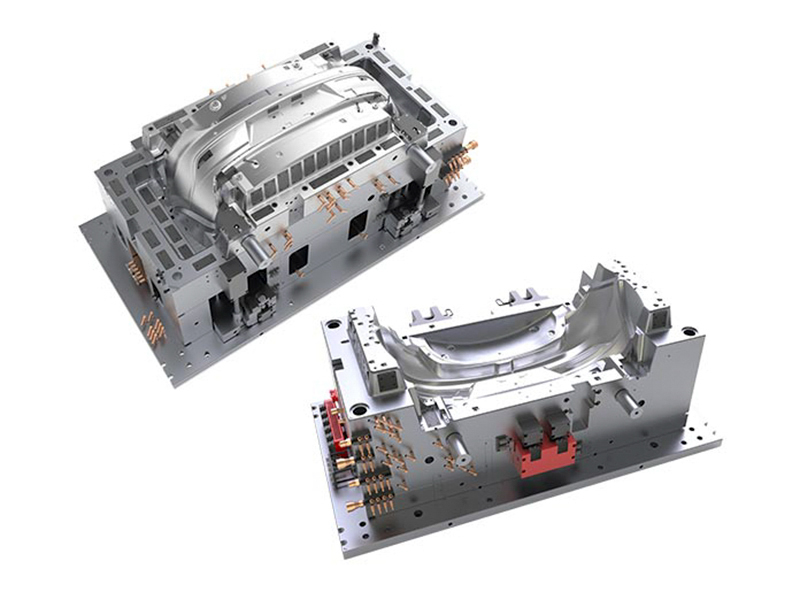

Geometric Considerations and Design Factors

The design of the mould plays a critical role in its response to heat treatment. Complex shapes, thin walls, or sharp corners can act as stress concentrators, making certain areas more prone to deformation or crack initiation. Engineers must carefully consider these factors during the design phase, incorporating features that promote even heat distribution and decrease stress concentrations. Symmetry and uniform wall thickness can reduce the risk, while fillets at sharp edges can prevent localized cracking during thermal cycling.

Heat Treatment Methods and Cooling Techniques

Different heat treatment methods can have varying impacts on the mould’s stability. Processes such as annealing, hardening, and tempering each introduce specific thermal cycles that must be carefully controlled. Quenching, in particular, poses a significant risk because rapid cooling can generate thermal gradients within the material. Employing controlled cooling techniques, such as staged quenching or the use of intermediate temperature baths, can alleviate internal stress. Additionally, preheating the mould prior to treatment and performing slow, uniform heating can further reduce the chance of distortion.

Preventive Measures and Post-Treatment Inspection

Preventing deformation and cracking requires a combination of careful planning, precise temperature control, and post-treatment inspection. Modern techniques, such as finite element analysis, allow engineers to simulate thermal stresses and predict potential problem areas before actual heat treatment. After treatment, dimensional checks, surface inspections, and non-destructive testing help identify any minor defects that may compromise mould performance. Adjustments and refinements at this stage can significantly extend the operational life of the mould.

Heat treatment is indispensable for enhancing the mechanical properties of moulds, but it inherently carries the risk of deformation and cracking. Material selection, geometric design, controlled thermal processes, and thorough inspection are all critical in mitigating these risks. By understanding the interplay between these factors, manufacturers can ensure that the moulds retain their precision and durability, providing reliable performance in high-demand production environments. Attention to these details helps prevent costly failures and extends the service life of essential tooling components, including Basket Moulds, without compromising quality.

Search...

Search... English

English