Unveiling the Ingenious Design of Foldable Crate Moulds

Foldable crate moulds have emerged as a cornerstone in the packaging industry, offering versatility, efficiency, and sustainability. These moulds enable the production of crates that can be conveniently folded when not in use, optimizing storage space and enhancing transport efficiency.

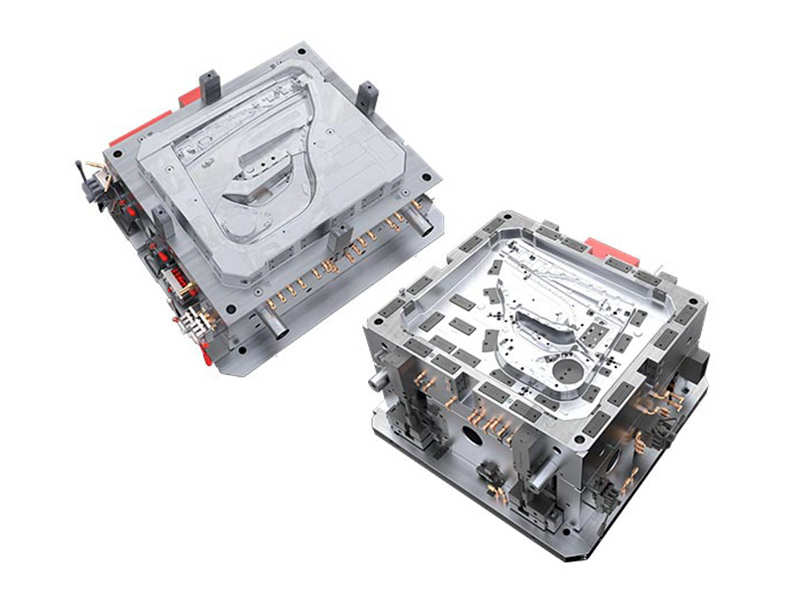

At the heart of foldable crate moulds lies a meticulously crafted structural composition. Typically, these moulds comprise multiple components, including a cavity, core, runner system, and ejection mechanism. The cavity and core form the internal shape of the crate, while the runner system facilitates the flow of molten material into the mould cavity during the injection moulding process. Additionally, an efficient ejection mechanism ensures seamless removal of the finished crate from the mould.

The manufacturing process of foldable crate moulds involves precision engineering and advanced manufacturing techniques. Initially, the design specifications are translated into computer-aided design (CAD) models, which serve as blueprints for mould fabrication. High-quality materials, such as hardened steel or aluminium, are then meticulously machined to create the various mould components. Subsequently, these components are assembled and subjected to rigorous testing to ensure dimensional accuracy and optimal performance.

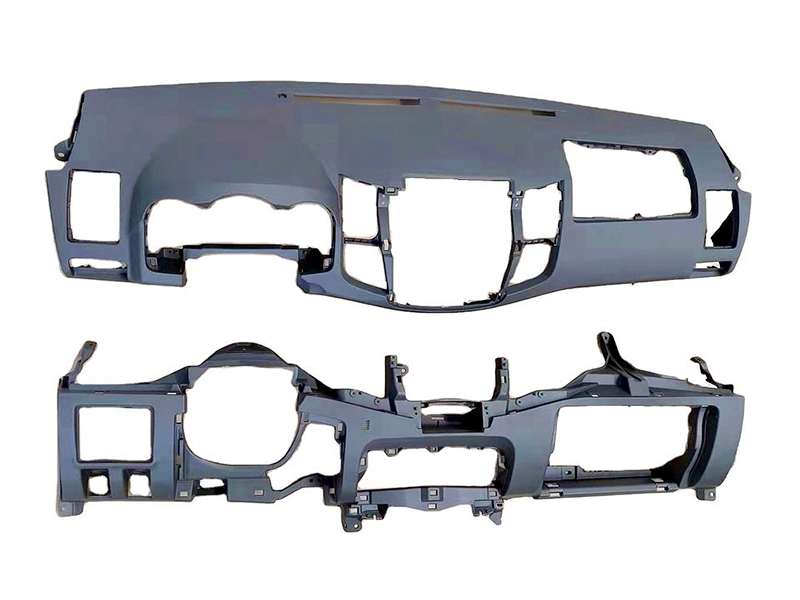

The design of foldable crate moulds is governed by several key considerations aimed at achieving functionality, durability, and cost-effectiveness. One crucial aspect is the incorporation of foldable features into the crate design, allowing for easy collapsing and unfolding while maintaining structural integrity. Additionally, attention is paid to optimizing wall thickness and ribbing patterns to enhance strength and rigidity without compromising material efficiency. Furthermore, considerations such as parting line design and venting ensure smooth moulding processes and high-quality finished products.

Foldable crate moulds offer a myriad of advantages that make them indispensable in the packaging industry. Firstly, their collapsible design enables significant space savings during storage and transportation, leading to reduced logistics costs and environmental impact. Secondly, the durable construction of these moulds ensures longevity and repeated use, contributing to sustainability efforts by minimizing waste. Moreover, foldable crates provide enhanced stackability and nesting capabilities, further optimizing storage and transportation efficiency.

The versatility of foldable crate moulds renders them suitable for a wide range of applications across various industries. In the food and beverage sector, these crates are utilized for the storage and transportation of fresh produce, dairy products, and beverages. In the retail industry, foldable crates serve as efficient display and storage solutions for merchandise and goods. Additionally, they find application in automotive, agriculture, and logistics industries, where efficient handling and storage of goods are paramount.

As the demand for sustainable packaging solutions continues to grow, foldable crate moulds are poised to play an increasingly significant role. Future innovations in material science and manufacturing technology are expected to further enhance the performance and versatility of these moulds. Moreover, advancements in automation and digitalization are anticipated to streamline the production process, making foldable crate moulds even more cost-effective and environmentally friendly.

In conclusion, foldable crate moulds epitomize the synergy of innovation and functionality in the packaging industry. Their intricate design, efficient manufacturing process, and diverse applications underscore their pivotal role in optimizing storage, transportation, and sustainability efforts.

Search...

Search... English

English

.jpg)