Using Advanced Technologies in Armchair Mould Fabrication

In the modern furniture manufacturing industry, the role of technology continues to evolve, influencing how products are designed, produced, and finished. One significant area where these advancements are clearly seen is in the fabrication of the Armchair Mould. This essential tool in chair production benefits from the integration of various advanced technologies, which improve efficiency, precision, and product quality. As the demand for high-quality seating options grows, so does the need for reliable and innovative mould solutions.

A crucial advancement in Armchair Mould fabrication is the widespread use of computer-aided design (CAD) systems. These systems allow mould designers to create highly detailed and accurate digital models of a Mould before any physical work begins. Through CAD, adjustments to dimensions, shapes, and contours can be made quickly to meet specific customer or market needs. The ability to visualise the final mould from every angle ensures that potential production challenges can be identified early in the process.

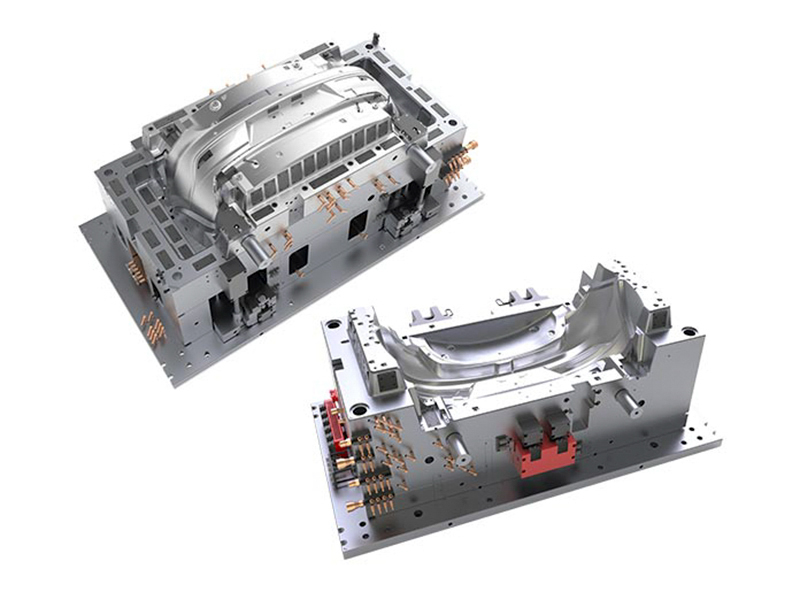

In addition to CAD, computer-aided manufacturing (CAM) software is now a standard tool in Armchair Mould production facilities. CAM works alongside CAD systems, translating the digital design into instructions for automated machines. This allows CNC (computer numerical control) equipment to cut, drill, and shape materials with a high degree of accuracy. CNC machining is particularly valuable in the production of Mould components because it ensures consistent results, even when producing complex designs with unique armrests or contoured backrests.

Another important technology transforming the fabrication of the Armchair Mould is simulation software. Before physically producing the mould, manufacturers can run digital simulations to predict how materials will behave during the moulding process. These simulations help identify issues such as uneven material distribution or potential shrinkage, enabling engineers to make necessary modifications to the Mould design. This step reduces trial-and-error production, saving time and material costs.

Material innovation is equally important in modern Armchair Mould fabrication. While traditional steel and aluminium continue to be used, newer materials such as high-strength alloys and engineered composites are being introduced. These materials are valued for their durability, heat resistance, and lighter weight, making them suitable for handling large, multi-component Mould systems. Certain advanced materials also offer improved surface finishes, which reduce sticking and simplify product release during the moulding process.

Surface treatment technology has also progressed in recent years. In the past, basic polishing and coatings were applied to protect the Armchair Mould and improve the appearance of finished products. Today, specialised coatings such as ceramic layers, anti-wear treatments, and anti-corrosion finishes are widely available. These advanced treatments extend the working life of a Mould and improve the consistency of the final product’s surface texture.

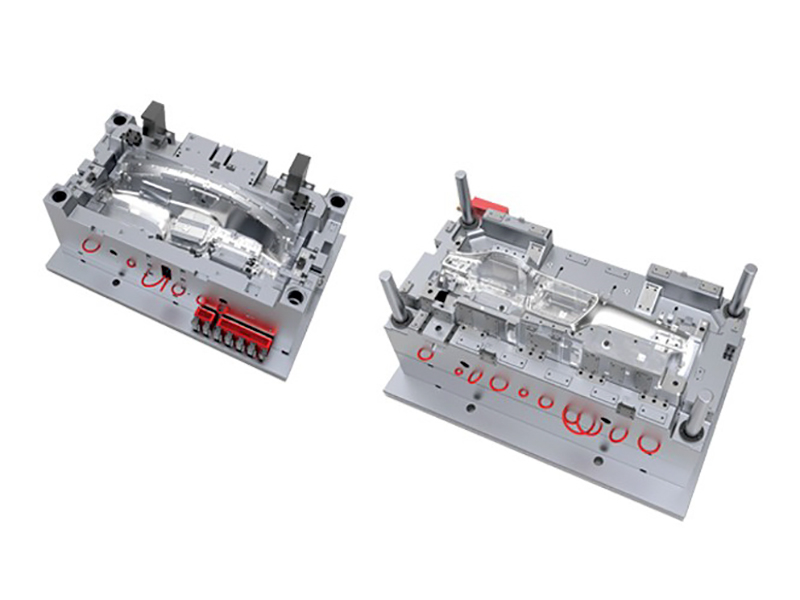

The rise of modular mould design is another development made possible by advanced technology. Traditional moulds were often fixed in form, limiting the range of designs manufacturers could offer. However, with modular Armchair Mould systems, different mould sections can be swapped out or adjusted without having to build an entirely new mould. This flexibility allows manufacturers to respond quickly to market trends and customer requests for new armchair styles.

3D printing technology is also beginning to influence the production of the Armchair Mould. While large-scale moulds are still typically made through CNC machining, 3D printing is increasingly used for creating prototype moulds, mould inserts, and small components. This technology allows for the fast production of test pieces, enabling manufacturers to evaluate new Mould designs quickly and cost-effectively.

Automation is making a noticeable impact on the way Armchair Mould production lines operate. Automated systems now handle various tasks such as material handling, component assembly, and quality inspection. These systems reduce labour costs, increase production speed, and improve consistency across mould production batches. Automation is particularly valuable for complex Armchair Mould systems, where precise alignment and assembly of multiple mould parts are necessary for performance.

Search...

Search... English

English

.jpg)