What Are The Steps Involved In Manufacturing An Automotive Mold?

Manufacturing automotive molds is a complex and precise process essential for producing various components of vehicles, such as body panels, interior parts, and engine components. These molds are used to shape materials like metal, plastic, or composite materials into the desired automotive parts. The following is a step-by-step guide outlining the key steps involved in manufacturing automotive molds:

1. Conceptualization and Design:

The process begins with the conceptualization of the automotive component or part that needs to be manufactured. Engineers and designers work together to create detailed 3D models or CAD (Computer-Aided Design) drawings of the part. These designs take into account factors like material selection, dimensions, tolerances, and production feasibility.

2. Material Selection:

Determine the appropriate material for the automotive mold. The choice of material depends on factors such as the type of part being manufactured, expected production volume, and the material's durability. Common materials for automotive molds include tool steel, aluminum, and various composite materials.

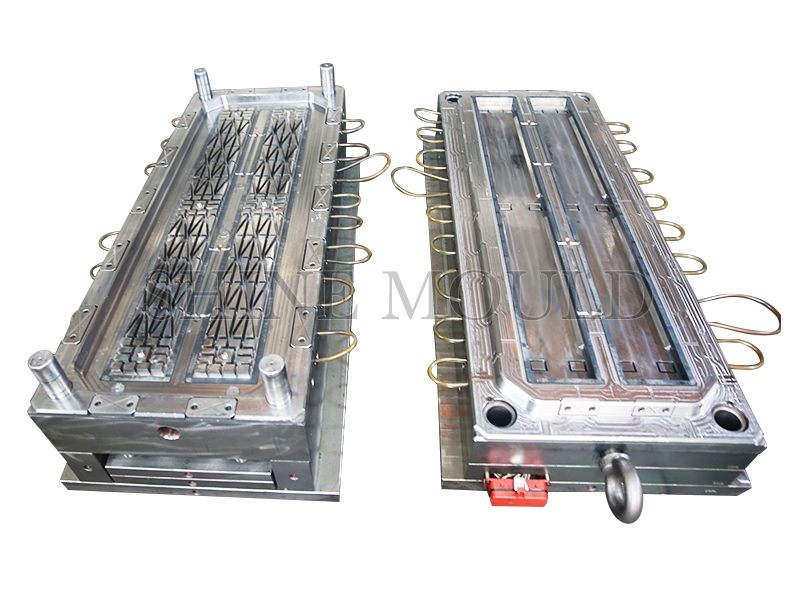

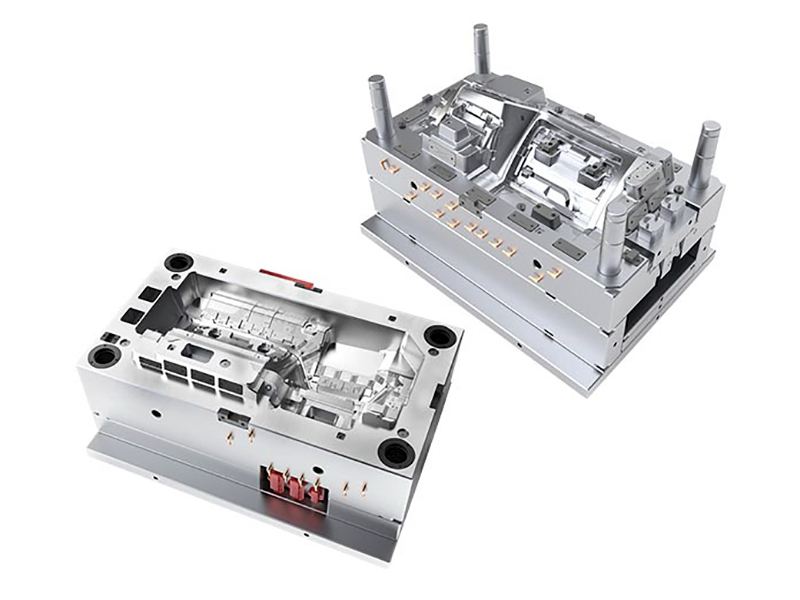

3. Mold Design:

The mold design phase involves the creation of two crucial components: the core and the cavity. These components define the final shape of the automotive part. The mold design must account for factors like draft angles, undercuts, and cooling channels. Additionally, the design should consider how the mold will be mounted in the molding machine.

4. Tooling and Machining:

Skilled toolmakers use CNC (Computer Numerical Control) machining, EDM (Electrical Discharge Machining), and other precision machining techniques to create the mold components. These processes ensure that the mold meets the exact specifications outlined in the design phase.

5. Mold Assembly:

Assemble the mold components, including the core and cavity, along with any necessary ejector pins, slides, and cooling channels. The mold's precise assembly is crucial for producing high-quality parts.

6. Mold Testing and Adjustments:

Before proceeding with mass production, it's essential to test the mold. This involves running sample production runs to check for defects, ensuring that the mold functions correctly, and adjusting as necessary. Mold testing helps identify and resolve issues like air traps, weld lines, or incomplete filling of the mold cavity.

7. Production Readiness:

Once the mold is tested and adjustments are made, it is considered production-ready. It is installed in an injection molding machine or other suitable machinery for the specific molding process.

8. Production:

The production phase involves injecting the chosen material (such as plastic or metal) into the mold cavity. The material is heated to a molten state and then injected under pressure. It fills the mold cavity and takes on the shape of the mold components. After cooling and solidifying, the molded part is ejected from the mold.

9. Quality Control:

Implement a comprehensive quality control process to inspect and test the molded automotive parts. This includes checking dimensions, surface finish, structural integrity, and any other specifications outlined in the design.

10. Maintenance and Repairs:

Regular maintenance and potential repairs of the mold are crucial for consistent quality and longevity. Cleaning, lubrication, and addressing any wear or damage are part of mold maintenance.

11. Scaling Production:

As demand for the automotive part grows, additional molds may be needed, or the production capacity may need to be increased through the use of multiple molding machines.

12. Documentation and Records:

Maintain detailed documentation and records of the mold's specifications, maintenance history, and any modifications or repairs made over time. This information is valuable for future reference and quality control.

13. Mold Storage:

Proper storage of molds is essential to prevent damage and ensure their longevity. Molds should be stored in a clean and controlled environment.

In summary, manufacturing automotive molds is a meticulous and multi-step process involving initial design, material selection, mold design, precision machining, assembly, testing, production, quality control, and ongoing maintenance. The quality and precision of the mold directly impact the quality and consistency of the automotive parts it produces, making it a critical component in the automotive manufacturing process. Collaboration with experienced mold designers and manufacturers is essential to ensure successful mold production for the automotive industry.

Search...

Search... English

English

.jpg)