What Factors Affect The Cost Of Making Children Toy Mold?

The cost of manufacturing children's toy molds can be influenced by a variety of factors, each of which plays a role in determining the overall expenses associated with the production of these molds. Understanding these factors is crucial for managing costs effectively.

Mold Material Selection:

The choice of material for the mold significantly affects the cost. Common materials for toy molds include steel and aluminum. Steel molds are durable but more expensive, while aluminum molds are lighter and less costly but may have a shorter lifespan. High-quality steel molds tend to be more expensive due to their durability and precision.

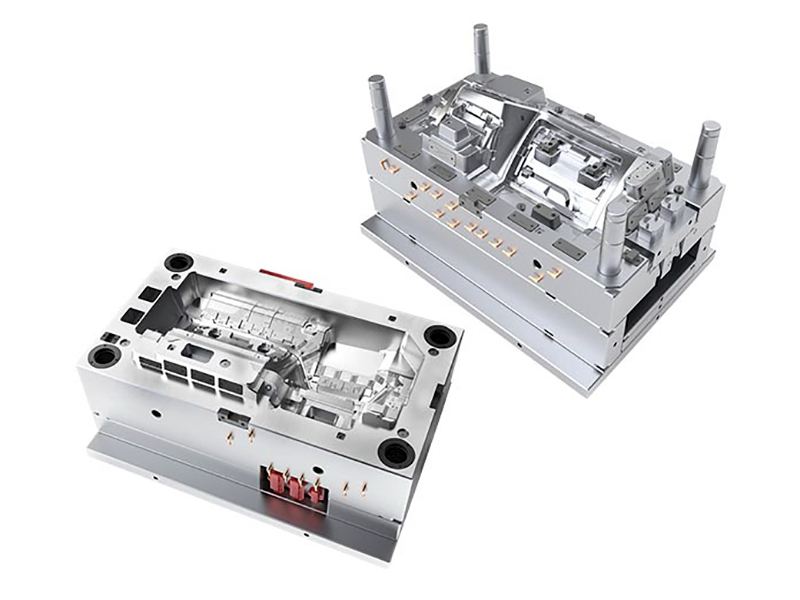

Mold Complexity:

The complexity of the toy mold design can greatly impact manufacturing costs. Complex molds with intricate shapes, multiple cavities, and tight tolerances are more expensive to produce than simpler molds. Complex molds require more machining and labor hours, driving up costs.

Mold Size and Weight:

The physical size and weight of the mold also affect the cost. Larger and heavier molds require more material and machining, leading to higher production expenses.

Surface Finish and Texture:

The desired surface finish and texture of the toy mold can influence costs. Molds that require a smooth, polished finish or intricate textures may require additional machining and labor, contributing to increased expenses.

Tolerances and Precision:

Tighter tolerances and higher precision in mold manufacturing demand more accurate machining and quality control processes. Achieving these specifications can increase costs, but it is often necessary for producing precise and high-quality toy components.

Production Volume:

The expected production volume of the toy molds plays a significant role in cost determination. Producing a larger quantity of molds may allow for cost savings through economies of scale, as some costs can be distributed over more units. Conversely, producing a single prototype or a small batch of molds can be more expensive per unit.

Lead Time and Urgency:

The urgency and lead time for manufacturing the toy molds can affect costs. Rushed projects often require additional resources and overtime, which can result in higher manufacturing expenses.

Labor Costs:

Labor costs can vary based on the complexity of the mold design and the skills required for manufacturing. Highly skilled mold makers may charge higher labor rates, especially for intricate or custom molds.

Mold Accessories:

Some toy molds may require additional accessories, such as ejector pins, cooling channels, or inserts. The inclusion of these accessories can impact the overall cost of the mold.

Mold Maintenance and Repairs:

Over time, molds may require maintenance and repairs to ensure consistent quality and longevity. Factoring in these ongoing costs is important when assessing the overall cost of mold ownership.

Quality Control and Testing:

Comprehensive quality control and testing processes can add to the overall cost. However, they are essential to ensure that the molds meet the required specifications and produce high-quality toy components.

Material Costs:

Beyond the mold material itself, other materials used in the manufacturing process, such as inserts, coatings, and surface treatments, can influence costs.

Regulatory Compliance:

Ensuring that the toy molds meet safety and regulatory standards may require additional testing and documentation, which can add to the cost.

Geographical Location:

The cost of manufacturing children's toy molds can also vary based on the geographic location of the mold maker. Labor and overhead costs may differ significantly between regions and countries.

The cost of manufacturing children toy molds is influenced by a combination of factors, including material selection, complexity of the design, production volume, labor costs, and quality control requirements. Careful consideration of these factors is essential to manage costs effectively while ensuring the production of safe and high-quality toy components.

Search...

Search... English

English

-1.jpg)