What is the mold production mold for toy molds?

Toy plastic mold is a tool that is matched with a plastic molding machine in the plastic processing industry to give plastic products a complete configuration and precise size. The different molding methods can be divided into different types of molds. So what is a toy plastic mold?

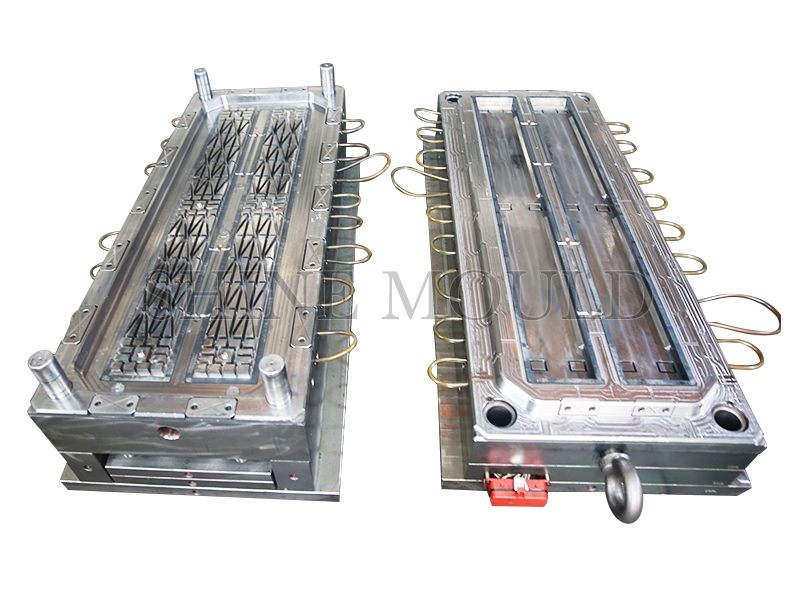

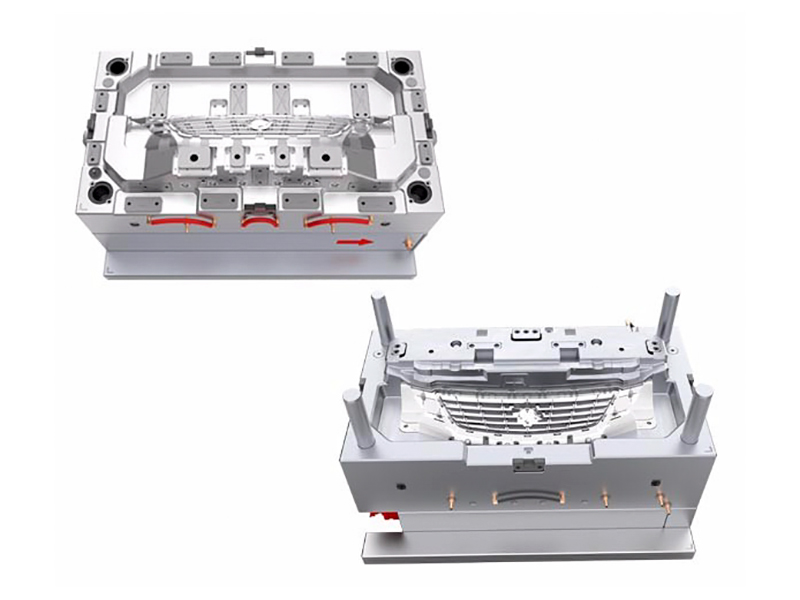

1. Injection mold. It is mainly a molding mold that is most commonly used in the production of thermoplastic parts, and the processing equipment corresponding to the plastic injection mold is a plastic injection molding machine. The plastic is first heated and melted in the heating barrel at the bottom of the injection machine, and then driven by the screw or plunger of the injection machine, enters the mold cavity through the injection machine nozzle and the pouring system of the mold, and the plastic is cooled and hardened to form and demolded to obtain the product. Its structure usually consists of forming parts, pouring system, guiding parts, pushing mechanism, temperature regulation system, exhaust system, supporting parts, and other parts. The manufacturing materials usually use plastic mold steel modules, and the commonly used materials are mainly carbon structural steel, carbon tool steel, alloy tool steel, high-speed steel, etc. The injection molding process is usually only suitable for the production of thermoplastic products. The plastic products produced by the injection molding process are very wide, ranging from daily necessities to various complex machinery, electrical appliances, and transportation parts. It is the most widely used processing method in the production of plastic products.

2. Blow mold. It is a mold used to form plastic container hollow products (such as beverage bottles, daily chemical products, and other packaging containers). The form of blow molding mainly includes extrusion blow molding and injection blow molding according to the process principle. , Injection stretch blow molding (commonly known as "injection stretch blow"), multilayer blow molding, sheet blow molding, etc. The equipment corresponding to blow molding of hollow products is usually called plastic blow molding machines, and blow molding is only suitable for the production of thermoplastic products. The structure of the blow mold is relatively simple, and the materials used are mostly made of carbon.

3. Extrusion die. A type of mold used to produce continuous-shaped plastic products, also known as extrusion molding head, is widely used in the processing of pipes, bars, monofilaments, plates, films, wire, and cable cladding, profiled materials, etc. The corresponding production equipment is a plastic extruder. The principle is that the solid plastic is melted and plasticized under the conditions of heating and the screw rotation of the extruder, and is made into the same cross-section as the shape of the die through a die of a specific shape. Continuous plastic products. Its manufacturing materials are mainly carbon structural steel, alloy tools, etc., and some extrusion dies are also inlaid with wear-resistant materials such as diamond on the parts that need to be wear-resistant. The extrusion process is usually only suitable for the production of thermoplastic products, which is significantly different from injection molds and compression molds in structure.

4. Blister mold. It is a kind of mold that uses plastic plates and sheets as raw materials to form some relatively simple plastic products. In the case of heating and softening, it is deformed and attached to the cavity of the mold to obtain the desired molded product, which is mainly used in the production of some daily necessities, food, and toy packaging products. Due to the low pressure during molding, the mold material is mostly made of cast aluminum or non-metallic materials, and the structure is relatively simple.

5. Compression mold. Including compression molding and injection molding two structural mold types. They are a type of mold mainly used to mold thermosetting plastics, and their corresponding equipment is a press molding machine. Compression molding method According to the characteristics of the plastic, the mold is heated to the molding temperature (generally 103°-108°), and then the measured compression molding powder is put into the mold cavity and the feeding chamber, the mold is closed, and the plastic is under the action of high heat and high pressure. It is a softened and viscous flow, and after a certain period of time, it will be solidified and shaped into the desired shape of the product. The difference between injection molding and compression molding is that there is a separate feeding chamber. Before molding, the mold is closed first. The plastic is preheated in the feeding chamber and is in a viscous flow state. Under the action of pressure, it is adjusted and squeezed into the mold cavity to harden and form. Compression molds are also used to form some special thermoplastics such as hard-to-melt thermoplastics (such as polyvinyl fluoride) blanks (cold pressing), resin lenses with high optical properties, slightly foamed nitrocellulose car steering wheels, etc. . The compression mold is mainly composed of cavity, feeding cavity, guiding mechanism, ejecting parts, heating system, etc. Injection molds are widely used in packaging electrical components. The materials used in the manufacture of compression molds are basically the same as injection molds.

6. High expanded polystyrene molding die. It is a kind of mold that uses expandable polystyrene (bead material composed of polystyrene and foaming agent) raw materials to form foam packaging materials of various desired shapes. The principle is that expandable polystyrene can be steamed in the mold, including two types of simple manual operation molds and hydraulic straight-through foam plastic molds, which are mainly used to produce packaging products for industrial products. The materials for making such molds are cast aluminum, stainless steel, bronze, etc.

Search...

Search... English

English

.jpg)